EV Charging Pile Manufacturer

4 days ago · Fast-Charging Piles deliver rapid, reliable EV charging with cutting-edge technology. High efficiency, smart energy management, and robust design ensure quick top-ups, reducing

A deployment model of EV charging piles and its impact on

Nov 1, 2020 · The promotion effect of direct-current charging piles on EV sales is twice that of alternating-current charging piles in the one-year simulation of our model. Increasing the

The World''s First Autonomous Piling System for Utility

3 days ago · Built engineers have spent thousands of hours developing an advanced autonomous solution that can rise to meet the challenges of utility-scale solar. Don''t compromise on your

Fully automatic energy storage charging pile group

A deployment model of EV charging piles and its impact The construction of public-access electric vehicle charging piles is an important way for governments to promote electric vehicle

Design and Research on Test System of AC and DC Charging Pile

Dec 31, 2021 · Design and research electric vehicle AC and DC charging pile test system, develop charging pile test system user interface, and complete automatic charging pile test.

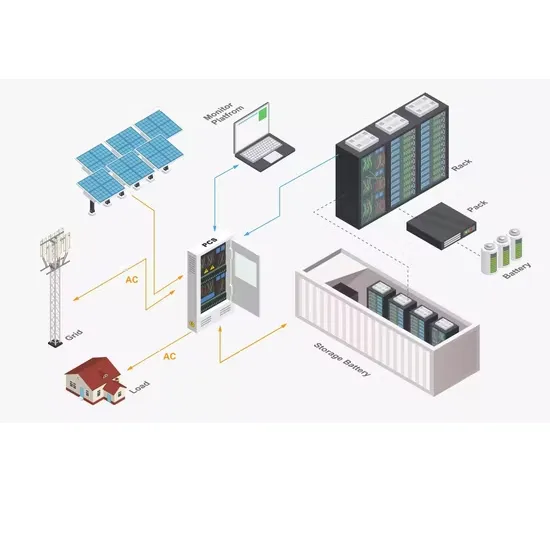

Working principle diagram of solar charging pile

Because of the popularity of electric vehicles, large-scale charging piles are connected to the distribution network, so it is necessary to build an online platform for monitoring charging pile

Solar charging pile installation design

In addition, when purchasing electric vehicles, users mainly consider whether the charging piles are fully equipped, whether charging is convenient enough, and whether it is feasible to install

EV charging fairness protective management against charging

Oct 15, 2024 · A ″1 to N″ automatic charging pile is proposed, which enables a single automatic charging pile to provide self-consistent charging and energy replenishment services for

The Future of Electric Vehicles: Exploring Electric Vehicle Charging Piles

Feb 28, 2024 · Characteristics: One key characteristic of an electri wind generator c vehicle charging pile is its ability to provide efficient and fast charging for plug-in electric vehicle

Fully automatic energy storage charging pile group

other inno In this paper, we make full use of the scale advantage of electric vehicles to construct a new type of highly efficient vehicle-pile-pile complementary energy storage The energy

Fully automatic energy storage charging pile within 100

Fully automatic energy storage charging pile within 100 000 Power balancing mechanism in a charging station with on-site energy storage unit (Hussain, Bui, Baek, and Kim, Nov. 2019). for

Technical Analysis and Research on DC Charging Pile of

Nov 22, 2021 · In recent years, with the improvement of human awareness of environmental protection, the emerging electric vehicle industry has developed vigorously. Meanwhile, as the

Fully autonomous solar panel cleaning robot from Greenleap

Nov 24, 2022 · The robot is powered by an on-board lithium battery and can complete a single cleaning cycle of a 1 MWp solar plant under 2.5 hours. The robot battery takes less than two

Design and implementation of an automatic charging

Aug 27, 2023 · An economic and practical method combined with the infrared sensor and laser sensor is developed to realize the accurate automatic charge docking. The phase-shifted full

Configuration of fast/slow charging piles for

Nov 23, 2024 · By arranging to charge piles of different types and capacities in different microgrid areas and formulating different charging price strategies, it

May 2024 Mobile Charging Robot Research Rep

May 22, 2024 · harging. In August 2023, Lotus Automatic Charging Robot and Solar Storage Supercharging Station settled in Fuyang District, hejiang. The supercharging station is

Advantages and disadvantages of solar automatic charging piles

Working principle, types and advantages of DC charging piles Advantages of DC charging piles. Compared with AC charging, DC charging piles have the following advantages: Fast charging

Shanghai''s first smart mobile facility for photovoltaic storage

Feb 11, 2025 · Situated on Sanhui Road, the station is equipped with two building integrated photovoltaic, one intelligent and mobile vehicle for energy storage and charging, as well as 22

6 FAQs about [Fully automatic station solar charging pile]

What are the characteristics of an electric vehicle charging pile?

As the electric vehicle charging pile (bolt) on the power distribution side of the power grid, its structure determines that the characteristics of the automatic communication system are many and scattered measured points, wide coverage, and short communication distance.

How does a charging pile work?

Charging piles generally provide two charging methods: conventional charging and fast charging. People can use a specific charging card to swipe the card on the human-computer interaction interface provided by the charging pile to perform corresponding charging operations and cost data printing.

What is the protection level of the charging pile (bolt)?

m) The protection level of the charging pile (bolt) complies with the IP54 requirements of “GB 4208-1993 Enclosure Protection Level (IP Code)”; The input end of the charging pile is directly connected to the AC grid, and the output end is equipped with a charging plug for charging the electric vehicle.

How to choose a charging pile (bolt)?

The charging pile (bolt) should have a good shielding function against electromagnetic interference; ⑤ The bottom of the pile (bolt) body should be fixedly installed on a base not less than 200mm above the ground. The base area should not be larger than 500mm×500mm; 3. Power requirements 4. Electrical requirements

How to choose a good AC charging pile?

The AC charging pile (bolt) should comply with IP54 (outdoor), and be equipped with necessary rainproof and sunscreen devices; 7. Three defenses (anti-moisture, anti-mildew, anti-salt spray) protection The printed circuit boards, connectors and other circuits in the charger should be treated with anti-moisture, anti-mildew, and anti-salt spray.

Can a robotic pile driver meet the challenges of utility-scale solar?

Built engineers have spent thousands of hours developing an advanced autonomous solution that can rise to meet the challenges of utility-scale solar. Don’t compromise on your tools. The RPD 35 is a fully autonomous robotic pile driver that combines four steps — surveying, pile distribution, pile driving, and data collection — into a single robot.

Update Information

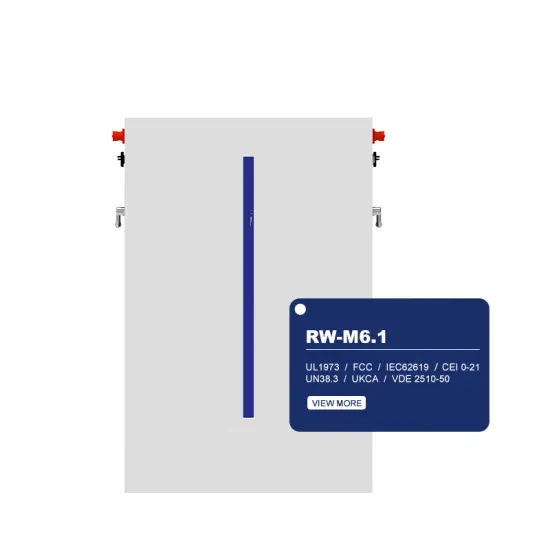

- Energy storage material of solar charging station

- Solar energy storage cabinet station charging voltage

- 5g micro base station and charging pile

- Which solar base station in Bishkek is the best

- Saint Lucia Solar Communication Base Station Factory

- Communication base station wind and solar complementary photovoltaic small

- Communication base station wind and solar complementary settled

- Solar power station in China in Korea

- What are the solar energy storage charging stations in Benin

- Tashkent Public Solar Base Station Lead-acid Battery

- China Solar Base Station Costs

- Container foldable solar charging panel

- Solar Home Power Station System

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.