Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

Stand‐alone multiple input photovoltaic inverter

Jun 9, 2020 · Design of multi-input inverter for extracting maximum power under weather intermittency and maintaining load voltage regulation for widely

Photovoltaic Inverter Reliability Assessment

Nov 5, 2019 · The switching model of the inverter contains the electrical models of the switches along with the topology of the power converter, passive components, electrical model of a PV

Maximizing photovoltaic system power output with a master

Jun 1, 2024 · The PV inverters waste power if the shared load power is less than their maximum output power. When shared load power surpasses the PV inverter''s maximum output power,

Maximum Power Output Control Method of

Jul 16, 2021 · Thus, a novel droop control method has been proposed to achieve the maximum power output of PV (MPO-PV) unit in this paper, where the PV units of parallel system always

Technical Note: Oversizing of SolarEdge Inverters

Oct 30, 2023 · PV inverters are designed so that the generated module output power does not exceed the rated maximum inverter AC power. Oversizing implies having more DC power than

Technical Information

Feb 4, 2025 · Grid operators frequently ask manufacturers of PV and battery inverters to provide maximum values of short-circuit currents. In other cases, the manufacturers are asked to

Improving PV plant performance via optimized inverter

Jan 23, 2025 · Researchers in Ireland have proposed, for the first time, a deterministic approach for designing inverter loading ratio (ILR) in utility-scale PV projects. The novel methodology is

Harmonics in Photovoltaic Inverters & Mitigation

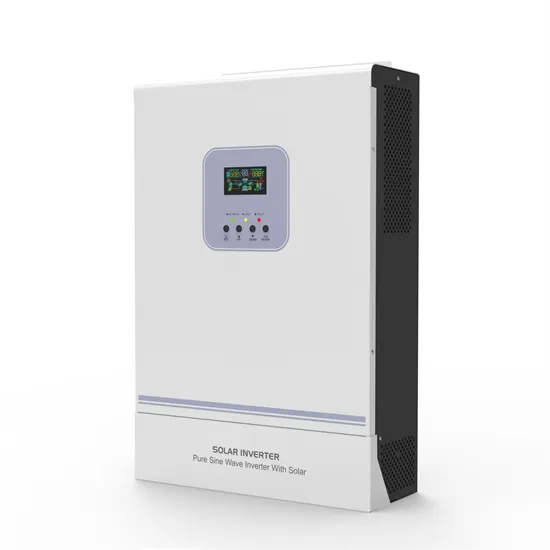

Dec 22, 2022 · PV Inverter System Configuration: Above g shows the block diagram PV inverter system con guration. PV inverters convert DC to AC power using pulse width modulation

difference between PV input and MPPT range

Aug 31, 2021 · this is my solar inverter datasheet i don''t get the difference between the MPPT and The PV input voltage my each pv in series should equal to 500v? or to 425?

The optimal capacity ratio and power limit setting method of the PV

Sep 1, 2023 · Reference [1] pointed out that improving the lifetime and reliability of photovoltaic inverters is of great significance for reducing the cost of photovoltaic power generation.

6 FAQs about [Maximum load photovoltaic inverter]

What is the maximum power rating of a PV inverter?

The maximum power rating is the amount of DC power that the inverter can accept from the PV array before it starts shutting down in order to protect itself from damage. This value is usually about 20-25% higher than the nominal power rating which refers to the AC power that the inverter can deliver under normal operating conditions.

What is a solar inverter capacity?

1. Understanding Inverter Capacity The capacity of an inverter is the maximum power output it can handle, usually measured in kilowatts (kW) or kilovolt-amperes (kVA). The goal is to match the inverter capacity with the solar array's size (in terms of power output) and the load (electricity demand) to ensure optimal performance.

Why do inverters have a maximum power rating?

The maximum power rating of inverters may be restricted by technical or financial constraints as the demand for MG power increases. Consequently, it is often necessary to operate multiple inverters in parallel to enhance the system's capacity (Baghaee et al., 2016).

What is a good inverter capacity for a grid-tied solar PV system?

A DC to AC ratio of 1.3 is preferred. System losses are estimated at 10%. With a DC to AC ratio of 1.3: In this example, an inverter rated at approximately 10.3 kW would be appropriate. Accurately calculating inverter capacity for a grid-tied solar PV system is essential for ensuring efficiency, reliability, and safety.

What is inverter loading ratio?

In this study, the inverter loading ratio is defined as: (1) ILR = P d c, peak P a c, peak where Pdc,peak is the maximum rated module power output for all modules in all strings at standard test conditions and Pac,peak is the inverter’s maximum AC power output.

How much power does a 20kW inverter need?

The first is the wattage rating. This is the maximum amount of power that the inverter can handle. For a 20kW system, you’ll need an inverter with a wattage rating of at least 20,000 watts. The second thing to consider is the type of AC output that you need. Most homes in the US use 120-volt AC power.

Update Information

- Maximum voltage of photovoltaic inverter

- Photovoltaic inverter load reduction

- Three-phase photovoltaic inverter maximum voltage

- Photovoltaic solar water pump inverter

- Photovoltaic inverter price trend

- Price of photovoltaic inverter in Milan Italy

- Bucharest photovoltaic inverter recommendation

- Typical two-stage photovoltaic inverter

- Photovoltaic inverter mw

- Does solar power require a photovoltaic inverter

- Capacity of photovoltaic inverter installation

- Photovoltaic energy storage inverter structure

- 1000 kW photovoltaic inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.