What are the Different types of Batteries used in Space?

Feb 11, 2025 · Space missions often require batteries that can be recharged multiple times, especially for long-duration missions such as those aboard satellites or rovers. Rechargeable

International Space Station (ISS) power system

Jan 26, 2014 · This article will outline the ISS power system, starting with the Solar arrays and moving into stability analysis criteria of the rest of the power

Space Battery Market Insights: Powering Satellites and Beyond

Nov 6, 2024 · Explore the growing space battery market, powering satellites, rovers, and missions with resilient technology for extreme space environments.

NASA and the Joint Center for Energy Storage Research

Mar 19, 2014 · NASA Glenn Research Center, Cleveland, Ohio and the DOE Joint Center for Energy Storage Research (JCESR) Argonne, Ill., are collaborating to develop next generation

A review on battery technology for space application

May 1, 2023 · In all this, an energy storage system (e.g., battery) with a primary energy source (e.g., photovoltaic) is a critical component of the spacecraft that ensures optimum operation

Are lithium batteries allowed in the International Space Station?

Jul 13, 2019 · Note that the batteries in the space station are purchased from known vendors and handled according to carefully reviewed procedures. The batteries on an airplane are of

Hubble Battery Tech Holds Power on Earth | NASA Spinoff

Feb 11, 2025 · Battery technology that has powered the International Space Station, the Hubble Space Telescope, and numerous satellites is now storing energy on Earth, enabling

Batteries – Space Steps

Oct 10, 2024 · Space-rated, Lithium-based battery cells can have energy densities of 120 to 140 W-hrs/kg, which can be twice what a Nickel-based cell offers. That''s the kind of big leap that

Solar in Space: Powering the International Space

Aug 7, 2017 · The first module was launched into orbit in 1998, and new modules continue to be added to the space station. In the nearly 20 years of continuous

Battery System Design, Testing, and Operation for the

Mar 13, 2024 · Mars 2020 mission required various power, energy storage, and distribution systems Includes power and pyrotechnic thermal batteries, baseload resistor assemblies,

Utility-Scale Battery Storage: What You Need To

Dec 6, 2023 · With the declining cost of energy storage technology, solar batteries are an increasingly popular addition to solar installations. It''s not just

International Space Station Electric Power System (EPS):

Nov 11, 2020 · The International Space Station (ISS) electrical power system consists of power generation, energy storage, power management, and distribution (PMAD) equipment.

6 FAQs about [What kind of energy storage battery does the space station use]

What batteries are used in space?

The primary batteries used for space applications include Ag Zn, Li-SO 2, Li-SOCl 2, Li-BC X, Li-CFx, and secondary rechargeable batteries are Ag Zn Ni Cd, Ni H 2, and Li-ion. In these battery systems, the Ag Zn battery was used in the early days of space missions such as the Russian spacecraft “Sputnik” and the US spacecraft “Ranger 3” .

Which rechargeable batteries are used in space missions?

The utilization of rechargeable batteries such as silver‑zinc (Ag Zn), nickel‑cadmium (Ni Cd), nickel‑hydrogen (Ni H 2), and lithium-ion (Li-ion) have been increasing in space missions , as shown in Table 8. Table 8. Battery chemistry deployed in different space missions.

What energy storage systems are used in space missions?

This review article comprehensively discusses the energy requirements and currently used energy storage systems for various space applications. We have explained the development of different battery technologies used in space missions, from conventional batteries (Ag Zn, Ni Cd, Ni H 2), to lithium-ion batteries and beyond.

Does ISS use a battery?

Public Use Permitted. The International Space Station (ISS) Electric Power System (EPS) currently uses Nickel-Hydrogen (Ni-H2) batteries to store electrical energy. The batteries are charged during insolation and discharged during eclipse.

Why are batteries important in space exploration?

Batteries are an essential part of the spacecraft when considering space exploration missions. Space operations and all the electronics, scientific equipment, and communications largely depend on the onboard battery power.

How much energy does a space station need?

The energy storage system required for these missions largely depends on the particular type of space application. For instance, satellite batteries used in geostationary earth orbit (GEO) preferably require 180 cycles per year, whereas medium earth orbit (MEO) requires 5500 cycles per year.

Update Information

- What kind of energy storage battery is the energy storage battery on the communication base station

- What is the use of lithium battery energy storage rack

- What are the power equipment of the communication base station battery energy storage system

- What kind of enterprise is energy storage cabinet battery

- What is cp in lithium battery energy storage power station

- What does the battery energy storage system of the Montenegro communication base station look like

- Doha Base Station Energy Storage Battery System

- Communication base station battery energy storage system design CAD

- Papua New Guinea s communication base station energy storage battery

- Safety distance specification for battery energy storage system of communication base station

- What are the lithium battery energy storage power stations in Sri Lanka

- Energy storage cabinet space analysis base station

- Nanya Communication Base Station Battery Energy Storage System Bidding Project

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

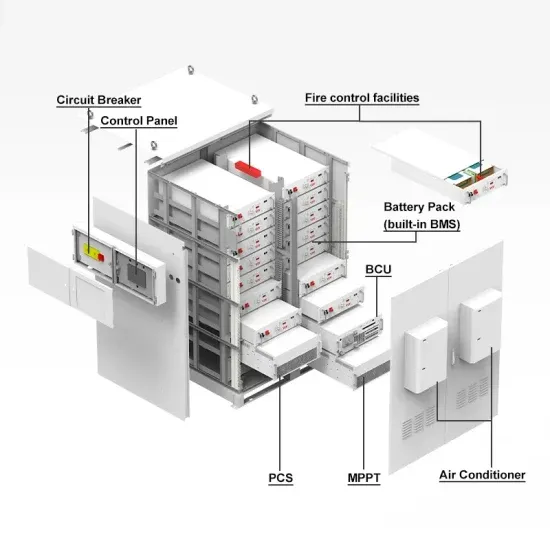

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.