How do pure sine wave inverters work?

Feb 11, 2022 · There are two main types of sine wave inverters: pure sine wave and modified sine wave. The former uses more expensive electronics to produce a more stable and smooth sine

Design and Simulation of Low Cost Pure Sin Wave

Aug 3, 2025 · Engr Shaiq Ali, Engr Muhammad Iftikhar Abstract— Pure sine wave transformers are very important nowadays when it comes to using ds power sources for both low and high

What Is Pure Sine Wave Inverter And Why Do

Jun 18, 2025 · A pure sine wave inverter (PSW) transforms direct current (from batteries, solar panels, or car batteries) into alternating current with a smooth,

How to Make a Pure Sine Wave Inverter Using the EGS002

A Pure Sine Wave Inverter is ideal for providing clean, stable AC power that mimics your mains supply. This is crucial for powering sensitive electronics like medical equipment, TVs, and

What You Need to Know About Pure Sine Wave

Apr 13, 2025 · Before diving into the details, you should first know that a pure sine wave inverter converts direct current (DC) into alternating current (AC) with a

Does "inverter generator" mean it is a "pure sine wave"

Jul 15, 2025 · I know that an inverter alone can be a "modified sine wave" or "pure sine wave", but the price difference is huge. Does this apply to "inverter generators"? When these companies

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · Here are the step-by-step processes involved in how a pure sine wave inverter works: DC Power Input: The pure sine wave inverter is connected to a DC power source, such

Highly Efficient Pure Sine-Wave Inverter for Photovoltaic

Mar 8, 2022 · Abstract—with the increase in the utilization of solar energy there is a need for renewable energy sources. A low frequency transformer is used to make project cost effective

Use a line conditioner to convert modified to pure sine wave?

Jul 29, 2013 · Dell claims it will stabilize voltage, not the wave. Sine wave is, basically, Hertz. A ''pure sine'' inverter very closely replicates the ''waves'' in which AC current flows while a

Smoothing modified sinewave Inverter | All About Circuits

May 21, 2009 · A pure sine-wave inverter uses Pulse-Width-Modulation at a high frequency to switch its Mosfets completely on and off so they stay fairly cool, then the high frequency is

Pure sine wave generation in battery-less solar system using

Jun 1, 2024 · If the system involves an inverter generating an electrical signal fed into a motor, and the mechanical output from the motor needs to be converted back into a pure sine wave, it

6 FAQs about [Inverter converted to pure sine wave]

What is a pure sine wave inverter?

A pure sine wave inverter is a type of power inverter that converts DC (direct current) power from batteries or other DC sources into AC power that can be used to power a wide range of electronic devices and appliances, including sensitive equipment such as laptops, refrigerators, air conditioners, and more.

What is the difference between a sine wave and an inverter?

Conventional AC power is produced by rotating machines (alternators) that produce a smooth alternation, like that of a pendulum. It is described mathematically as a “sine wave”. It is the ideal waveform for the transfer of AC power. An inverter is an electronic device that converts DC to AC through a switching process.

Do you need a sine wave inverter?

When a pure sine wave inverter isn’t necessary if you have electronic devices that use rectifiers to convert AC to DC, then you probably don’t need a pure sine wave inverter. However, most electronic devices run just fine on a modified sine wave. How do you turn a square wave into a sine wave?

What is the output voltage of a sine wave inverter?

Typically, the output voltage is at 120V or 230V level depending on the region, and the frequency is 50Hz or 60Hz. Pure sine wave inverters are good at handling power conversion efficiently and generally in the range of 85% to 95% efficiency, which means more of the DC power is successfully converted into high-quality AC power.

What is a modified sine wave inverter?

Modified sine wave inverters and pure sine wave inverters are two types of power inverters. The main difference between them lies in the quality and characteristics of the AC waveform they produce.

Is a pure sine wave inverter better than a modified sine wave?

In summary, pure sine wave inverters are generally considered to be more suitable for powering sensitive electronic devices and appliances, while modified sine wave inverters may be a more cost-effective option for basic power needs. When Do You Need a Pure Sine Wave Inverter?

Update Information

- Lebanon pure sine wave 20kw inverter for sale

- Branded industrial frequency pure sine wave inverter

- Amman pure sine wave 50kw inverter

- How to choose pure sine wave inverter

- Huawei pure sine wave inverter price

- Which pure sine wave inverter 12v is better

- Pure sine wave inverter 24v low power

- Pure sine wave 1300 watt inverter

- Smart inverter pure sine wave

- Price quote for pure sine wave inverter in Zurich Switzerland

- Pure sine wave inverter chassis

- Luxembourg pure sine wave 20kw inverter company

- Zimbabwe pure sine wave inverter

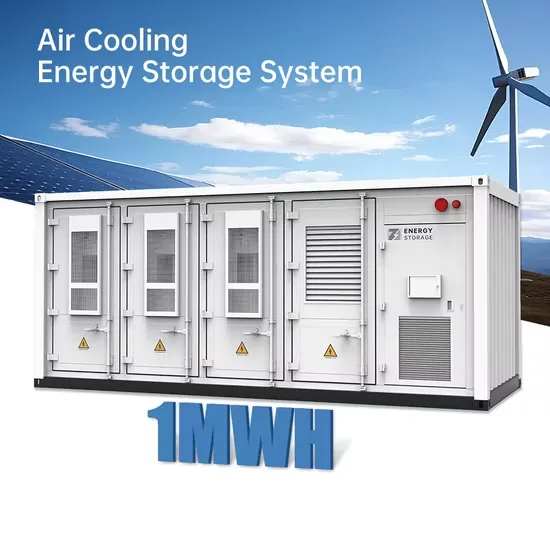

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

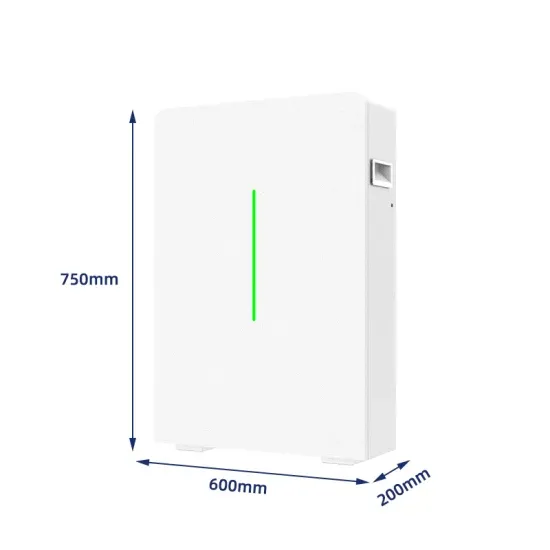

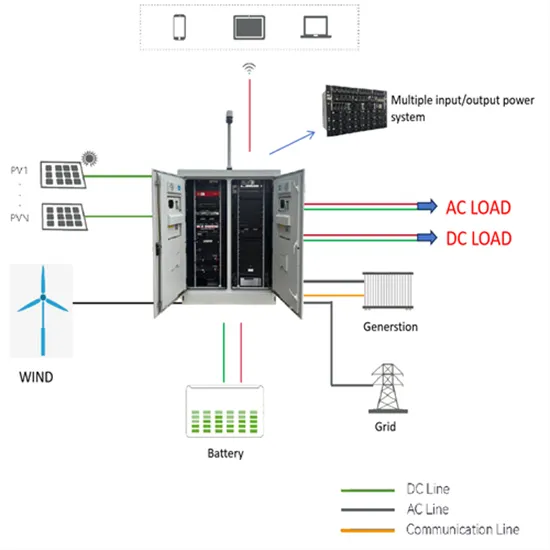

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.