Integrating Geothermal Waste Heat into Solar Chimney Power

Mar 15, 2025 · A solar chimney power plant (SCPP), also known as a "solar chimney" or simply a "solar tower," is a renewable energy power plant that converts solar energy into electricity. Due

A review of heat recovery applications for solar and geothermal power

Oct 1, 2019 · Through a combination of sustainable and hybrid solutions and reusable waste heat methods, a sustainable future for power and advanced technology can be made a reality.

Biogas and photovoltaic solar energy as renewable energy in

Sep 1, 2024 · However, in general, solar PV is primarily used in hybrid configurations with anaerobic digestion at WWTPs with flow rates greater than 1.89 × 10 4 m 3 /d, where solar

Thermal power fluctuations in waste heat to power systems:

Apr 1, 2018 · Waste Heat Recovery (WHR) systems basically transfer waste energy to a heat carrier or storage system. This waste heat can be subsequently utilized directly as thermal

Photovoltaic cooling and residual heat power generation via

Mar 1, 2025 · In this paper, a dual-function photovoltaic cooling-thermoelectric generator (PVC-TEG) device composed of a PV cell, a TEG module and a hygroscopic hydrogel was

Enhancing concentrated photovoltaic power generation

Sep 15, 2024 · This study proposes a novel coupled Concentrated Photovoltaic System (CPVS) and Liquid Air Energy Storage (LAES) to enhance CPV power generation efficiency and

A molten salt energy storage integrated with combined heat and power

Dec 30, 2024 · To investigate the flexibility and economic characteristics of a molten salt-combined heat and power (CHP) integrated system under different heat sources, this paper

Photovoltaic energy storage and waste heat power generation in steel plants

The system can also integrate waste heat from industrial processes, such as thermal power generation or steel mills, at stage 3, recovering additional energy. Take a virtual tour of

Study on the coupling of the iron and steel industry with

Apr 1, 2025 · Based on this, this study investigates information about steel plants and photovoltaic power plants in China, summarizes steel production and PV power generation in each

Thermoelectric Generation Technology Using Waste

Oct 2, 2024 · Thermoelectric generation is one of the promising technologies expected to play an important role for steel plant''s waste heat recovery, par-ticularly radiant heat from steel

Flexibility improvement of a coal-fired power plant by the

Sep 30, 2024 · This study presents a novel method to enhance the flexibility of coal-fired power plant (CFPP). The suggested integrated system comprises a CFPP integrated with molten salt

Performance analysis on a hybrid system of wind, photovoltaic

Dec 1, 2024 · The combined heat and power generation (CHP) is an efficient and economical solution to the intermittency and instability faced by renewable energy power and however, the

Application of Molten Salt Thermal Energy Storage for Waste Heat

Sep 24, 2024 · In this study, an overview of the distribution and characteristics of waste heat resources in steel industry is provided firstly. Then the potential of integrating molten salt

Recent Development of Thermophotovoltaic System for Waste Heat

Jun 1, 2020 · Rapid depletion of fossil fuels due to the growing demand for energy has resulted in a worldwide concern to improve energy conversion efficiency. Yet, the energy conversion of

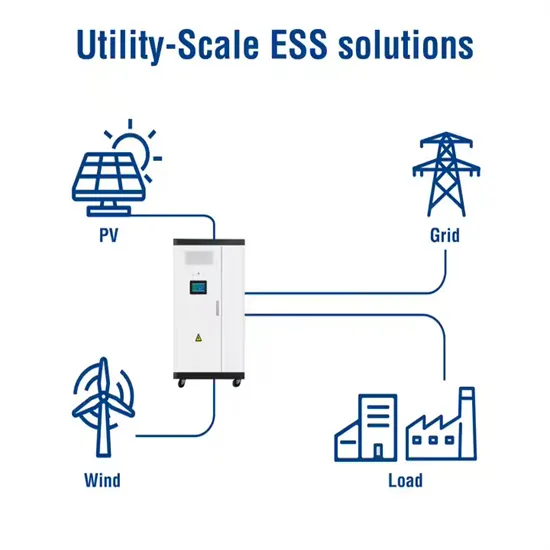

Overview on hybrid solar photovoltaic-electrical energy storage

May 1, 2019 · To compensate for the fluctuating and unpredictable features of solar photovoltaic power generation, electrical energy storage technologies are introduced to align power

A comprehensive review on renewable energy integration for combined

Nov 5, 2020 · Over the past decades, combined heat and power systems have been associated with energy savings and less environmental consequences. To this end, these systems

Fluctuating waste heat characteristics in steel plants:

May 1, 2025 · To address these fluctuations, this study proposes tailored utilization schemes that incorporate heat storage and an adjustable flow rate. The scheme demonstrated substantial

Thermoelectric Generation Technology Using Waste

Oct 2, 2024 · 1.1 Thermoelectric Power Generation Technology Using Waste Heat in Steel Works Waste heat generated in steel works is an important energy source, and many types are

WASTE HEAT TO POWER SYSTEMS

Apr 29, 2022 · Introduction Waste heat to power (WHP) is the process of capturing heat discarded by an existing thermal process and using that heat to generate power (see Figure 1). Energy

Waste heat recovery: Converting heat to power

Jun 19, 2022 · ses is commonly used to generate steam an 42 ssing, is estimated at between 5.0 and 7.5GW. The Waste Heat Recovery (WHR) based power plant installed in the iron and

Addressing industrial waste heat supply variability with

Mar 1, 2025 · The conversion of waste heat to power presents a significant opportunity to enhance industries'' energy efficiency. However, power generation often varies based on market

Power-to-hydrogen storage integrated with rooftop

Feb 28, 2024 · For example, integration of wind power, hydropower and photovoltaic (PV) systems with biomass-based energy plants in Finland [16], CHP integrated with renewable

Towards highly efficient solar photovoltaic thermal cooling by waste

Jul 1, 2024 · Excessive waste heat affects the lifespan of PV systems, leading to abnormal operating temperatures. In this notion, Photovoltaic-thermal (PV/T) systems are introduced to

A review of energy storage technologies for large scale photovoltaic

Sep 15, 2020 · Energy storage can play an essential role in large scale photovoltaic power plants for complying with the current and future standards (grid codes) or

Discussion on the Application of Rooftop Photovoltaic Power

Jan 16, 2020 · In this paper, the installation of rooftop distributed PV power plants in iron and steel enterprises, including analysis of solar energy resources, selection of PV operation modes,

The economic use of centralized photovoltaic power generation

Jan 15, 2025 · Firstly, the costs of photovoltaic power generation, photovoltaic hydrogen production, and photovoltaic energy storage were calculated in more detail to obtain the total

Proceedings of

Mar 2, 2021 · Integrating solar photovoltaics (PV) at steel plants is promising to reach the target. This paper investigates the potential capacity, potential output and economic performance of

Solar power generation by PV (photovoltaic) technology: A

May 1, 2013 · Solar power is the conversion of sunlight into electricity, either directly using photovoltaic (PV), or indirectly using concentrated solar power (CSP). The research has been

Potential assessment of photovoltaic power generation in

Feb 1, 2022 · The spatial distribution characteristics of PV power generation potential mainly showed a downward trend from northwest to southeast. Meanwhile, there were clear spatial

Fluctuating waste heat characteristics in steel plants:

May 1, 2025 · This study focuses on a steel plant in Hebei Province, China, with an annual production capacity of 10 Mt. It systematically examines waste heat sources in key processes,

Current progress of process integration for waste heat

Apr 15, 2023 · According to a review of research studies conducted on waste heat recovery in the iron and steel sector, thermal terminal analysis, exergy analysis, and mathematical modeling

6 FAQs about [Photovoltaic energy storage and waste heat power generation in steel plants]

Is waste heat energy a future for the steel industry?

.Author: Arun Mote Triveni TurbineEfÞcientrecycling of waste heat energy resources is the future for the global iron and steel industry, but conversion of heat o power remains a challenge in a steel plant. The potential for saving energy through the application of advanced technologies to the utilization of waste heat, is higher in deve

Do photovoltaic power plants need dedicated energy storage centers?

Although this study calculated the power generation of the photovoltaic power plants, to ensure stable direct power supply and improve the system's resilience to fluctuations, it is recommended to establish dedicated energy storage centers for power storage and distribution.

How to identify steel plants suitable for integration with photovoltaic power plants?

Analytic hierarchy process (AHP) is then used to identify the steel plants suitable for integration with photovoltaic power plants. The EDSAC evaluation model sets five assessment indicators: emission reduction effectiveness, distance effectiveness, supply effectiveness, anti-volatility effectiveness, and cost effectiveness.

Can photovoltaic systems improve low-carbon production in Chinese steel plants?

To this end, a model based on distance and electricity demand matching, as well as a related evaluation framework, was developed to assess the suitability of 380 Chinese steel plants for low-carbon production with the integration of photovoltaic systems.

Can photovoltaic power plants produce low-carbon energy?

The low-carbon production pathway through the coupling of ISI with photovoltaic power systems is explored in this study. The capacity and carbon emissions of 380 steel plants are investigated, and the annual power generation of 10,345 photovoltaic systems is estimated.

How many GW is a Ssing power plant?

ssing, is estimated at between 5.0 and 7.5GW. The Waste Heat Recovery (WHR) based power plant installed in the iron and steel industry uses heat generated through coke dry quenching (CDQ), sinteri

Update Information

- Photovoltaic energy storage cabinet photovoltaic power generation

- Photovoltaic power generation and energy storage in western Grenada

- Baghdad photovoltaic power generation and energy storage

- Britain s photovoltaic power generation and energy storage advantages

- Huawei Niamey Photovoltaic Energy Storage Power Generation Project

- Summer photovoltaic energy storage power generation in Hamburg Germany

- Photovoltaic panels for energy storage and power generation

- Photovoltaic power generation system according to energy storage

- Photovoltaic power generation energy storage battery configuration parameters

- Stockholm energy storage photovoltaic power generation power

- Maximum energy storage for photovoltaic power generation

- Bangui exports solar photovoltaic power generation and energy storage systems

- Photovoltaic power generation energy storage charging and battery replacement

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.