Dynamic Power Management for 5G Small Cell Base Station

Jan 9, 2021 · 5G networks with small cell base stations are attracting significant attention, and their power consumption is a matter of significant concern. As the increase of the expectation,

Should I Keep My Base Stations Plugged In: Unveiling the

Sep 26, 2024 · In our modern society, where reliance on technology is paramount, base stations have become an indispensable part of our daily lives. However, the question arises as to

Maintenance of work equipment

Jul 11, 2025 · Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. It may be part of a planned

Maintenance Points for Telecom Base Station Batteries

(1) Insulating mats should be arranged in the battery pack maintenance channel. (2) Batteries of different manufacturers, capacities, and models are strictly prohibited from being used in the

Mobile communication base station power supply equipment maintenance points

Oct 14, 2022 · The key points of the maintenance of the base station dynamic environment monitoring system are to prevent the system''s false alarm situation, improve system stability,

Management and maintenance of base station

Dec 11, 2024 · This article focuses on the three parts of switching power supply: "types and usage scenarios, configuration principles and algorithms, and daily

Maintenance KPIs & Metrics to Measure Performance | Fiix

Jan 14, 2022 · What are maintenance key performance indicators (KPIs)? Key performance indicators (KPIs) measure the performance of a person, department, project, or company over

Power Station Maintenance: Which Strategy Is Best?

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

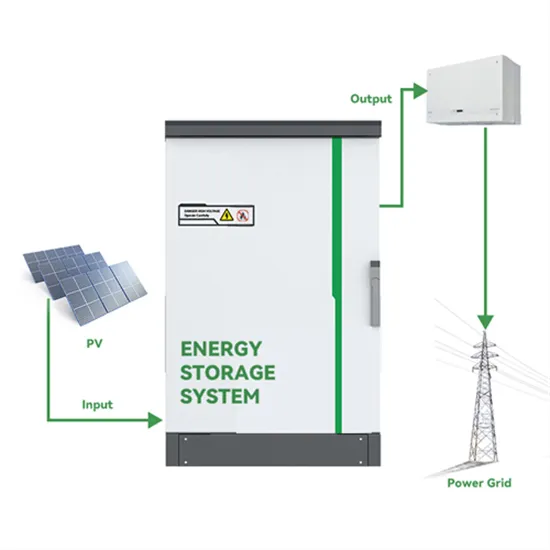

A Simple Guide to Energy Storage Power Station Operation and Maintenance

Sep 3, 2024 · In this blog post, we''ll break down the essentials of energy storage power station operation and maintenance. We''ll explore the basics of how these systems work, the common

Maintenance points for power supply equipment of mobile

Battery maintenance is the focus of the entire power supply maintenance work, and all power supply maintenance revolves around this work. Generally speaking, the key to the

How to Maintain Backup Power Supply for Telecommunications Base Stations?

By following these maintenance practices and implementing robust monitoring and testing procedures, telecommunications operators can ensure the reliability and effectiveness of

Electrical Preventive Maintenance and Checklist

Apr 3, 2024 · Learn the basic checklist for electrical preventative maintenance to ensure the dependability, efficiency, and safety of your electrical systems.

Maintenance BestPractices & Intervals for Substation

Oct 24, 2017 · Maintenance BestPractices & Intervals for Substation Equipment Presented by: Paul Schlies, President/CEO Energis High Voltage Services, Inc.

CHAPTER 10 OPERATION AND MAINTENANCE

May 9, 2004 · Internal lease fees of the digital streams (E-1 base) are to be reasonably defined considering the coming competitors in the near future.(Initial cost and maintenance /operation

Power Base Stations Predictive Maintenance | We Group

The Hidden Costs of Reactive Maintenance Industry data reveals 43% of tower site failures originate from power systems. The PAS (Problem-Agitate-Solution) framework exposes three

Base Stations and Cell Towers: The Pillars of

May 16, 2024 · Base stations and cell towers are critical components of cellular communication systems, serving as the infrastructure that supports seamless

Exploration of Key Technologies for Equipment Operation and Maintenance

Nov 1, 2023 · The article proposed a long-term maintenance research method for the key technologies of equipment O&M in the new PS, achieving precise management and efficient

6 FAQs about [What are the key points of base station power maintenance]

What is the ideal maintenance strategy for a power station?

The ideal maintenance strategy is about applying the right measures at the right times. However, there are no silver bullets for power station maintenance. In complex systems, the causes that may result in defects and hazards are many and varied.

What maintenance activities can be performed while a power station is in operation?

Certain maintenance activities can be performed while the power station is in operation, especially those involving condition monitoring, routine inspections, and minor repairs. However, major overhauls or repairs may require planned outages or shutdowns to ensure the safety of personnel and uninterrupted power supply.

What is power station maintenance?

Power station maintenance refers to the regular activities and strategies implemented to ensure the optimal performance, reliability, and safety of power generation equipment and systems. Q: Why is maintenance important for power stations?

How can power station operators ensure safety during maintenance?

Cybersecurity measures during power station maintenance may include regular system updates, network segmentation, employee training on cybersecurity awareness, and continuous monitoring to protect control systems and data from cyber threats. Q: How can power station operators ensure safety during maintenance activities?

What are the different types of power station maintenance?

Power station maintenance can be broadly categorized into three main types: Preventive maintenance involves regular inspections, servicing, and replacement of components based on predetermined schedules or manufacturer recommendations. It aims to prevent breakdowns, improve equipment life, and maintain optimal performance.

What happens if a power station is not maintained?

Lack of investment in maintenance could potentially have costly consequences. Besides safety risks, defects in power stations often result in cost-intensive remediation measures and temporary loss of power production. The ideal maintenance strategy is about applying the right measures at the right times.

Update Information

- What does the mobile base station power supply include

- What is the power supply type of 5g base station equipment

- What are the outdoor base station power supply systems

- Communication base station wind power maintenance company

- What is the use of base station power module

- What are the power equipment of the communication base station battery energy storage system

- What is the power of the solar energy storage ESS of the communication base station

- Base station emergency power supply maintenance

- Seychelles communication base station wind power line maintenance

- How many 5G base station photovoltaic power generation system points are there in Vaduz

- What does wind power and photovoltaic power generation include in the San Salvador communication base station

- What is the power supply of BESS outdoor base station in Guinea

- What are the power supply equipment for communication base station inverters

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.