What Inverter Size Do I Need to Run a Coffee Maker?

Coffee maker watts + 20% = inverter size If your coffee machine uses 1000 watts, the inverter has to be 1200 watts minimum. Because inverters are not 100% efficient, some power is lost

Inverter Efficiency: Understanding How Much Power You''re

Jul 21, 2025 · Have you ever wondered how much power you''re actually getting from your inverter? Many people think that once they connect their solar panels and batteries to an

How much watts are Victron inverters use to function?

May 15, 2022 · Hi everyone, Is there a tab somewhere to see how much watts victron inverters uses to produce a specific load? I am surprised that my 3kw multiplus is mostly using 50% of

Inverter Efficiency: Understanding How Much Power You''re

Jul 21, 2025 · Most modern inverters have efficiency ratings between 90% and 98%. Let''s break it down: If you feed 1000 watts of DC power into your inverter and it outputs 950 watts of AC

How Many Watt Inverter Do I Need? | Click to Learn More

Mar 20, 2025 · Introduction Selecting the accurate solar inverter size is extremely important if you want your electrical appliances should function properly without over-loading the machine.

Solar panel microinverters: the expert guide [UK,

May 19, 2025 · Microinverters work in low light. While string inverters generally need between 60 and 200 volts to start producing electricity, microinverters

Frequently Asked Questions About Power Inverters

Power Inverter FAQ Frequently Asked Questions about Power Inverters What does a power inverter do, and what can I use one for? Using an inverter for basic emergency home backup

How Many Watt Inverter Do I Need? | Click to Learn More

Mar 20, 2025 · If the total power requirement is 800W, an inverter rated to support 1000W or higher is highly suggested. Many choose inverters that can support the maximum load or the

Running Inverters in Parallel: A Comprehensive

Jul 14, 2023 · This setup ensures efficient and uninterrupted electricity supply, offering flexibility and scalability for growing power requirements. Running

I have 370w panels with iq8+ inverters. How many watts are

Jul 3, 2025 · So, your IQ8+ micros are 290VA of power. You figure your true power ratio is about 370W x 0.89 ÷ 290VA or ~1.14 which is ok. A real good power ratio is anything above or close

How Many Watts Does a Solar Panel Produce Under Real

Aug 8, 2025 · The direct answer to how many watts does a solar panel generates is based on watts or kW, and the energy produced by the panel in real life creates a difference between

Efficiency of Inverter: Calculation & Equation

Mar 4, 2023 · As a result, the efficiency of the inverter equals P ac /P dc, where P ac denotes ac output power in watts and P dc denotes dc input power in

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages. First stage is high frequency DC to DC

Everything you need to know about inverters

Sep 12, 2024 · Everything you need to know about inverters Inverters are your saviour from time consuming power cuts and the solution to all your energy requirements! One of the greatest

6 FAQs about [How many watts are considered low power inverters]

What if inverter load is less than 15%?

In general, if the inverter is loaded less than 15%, the efficiency will be low. As a result, a good match between inverter capacity and load capacity will allow us to obtain more efficiency, which is more ac output power from the inverter for the same DC input power. Efficiency of Inverter per Output Power (Reference: inverter.com)

How much power does a 200W inverter use?

As a result, if you’re utilizing 20 watts of AC power, the inverter will be pulling 40 watts from the batteries, resulting in a 50 percent efficiency. A modest 200W inverter, on the other hand, may only use 25 watts from the battery to produce a 20-watt AC output, resulting in an 80 percent efficiency.

What percentage of power does an inverter have a high efficiency?

Below 10-15% of power output, efficiency is quite low. At high output power, the efficiency is steadily high with some small variations. The behavior in Figure 11.8 partially results from the fact that stand-by losses for an inverter are the same for all output power levels, so the efficiency at lower outputs is affected more.

How much power does an inverter need?

It’s important to note what this means: In order for an inverter to put out the rated amount of power, it will need to have a power input that exceeds the output. For example, an inverter with a rated output power of 5,000 W and a peak efficiency of 95% requires an input power of 5,263 W to operate at full power.

How much power does a 1000W inverter use?

In general, the standby power consumption of most inverters is relatively low, typically less than 1% of their rated power output. For a 1000W inverter, the average idle power consumption could be around 10-20 watts, while for a 2000W inverter, it could be around 20-40 watts.

How much power is lost in an inverter?

Suppose the efficiency of the inverter is 90 percent, then 10 percent of the power is lost in the inverter. It depends on the load as to how efficient the inverter will be. Generally speaking, it is usually at its peak at about two-thirds of the capacity of the inverter.

Update Information

- How many watts does 12v solar power generate

- How to match low power inverter with photovoltaic panels

- How many watts can an outdoor power supply connect to

- How many watts of solar power does Egypt generate

- How many watts is the efficiency of solar power generation

- How many watts of solar power modules should I buy

- How many watts is suitable for mobile energy storage power supply

- How many watts does a full set of solar power supply have

- How many watts of solar power generation durability

- How many watts of solar power can be generated by 2 million

- How many kilowatts of solar photovoltaic power per 100 square meters

- How many power signal base stations are there in Gitega

- How many watts does a 20-foot energy storage container have

Solar Storage Container Market Growth

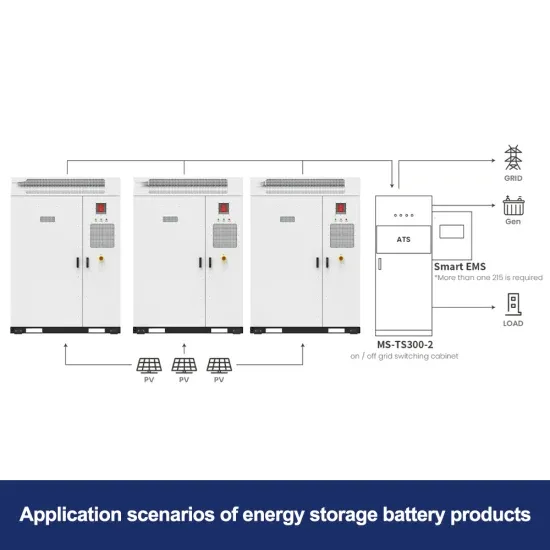

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

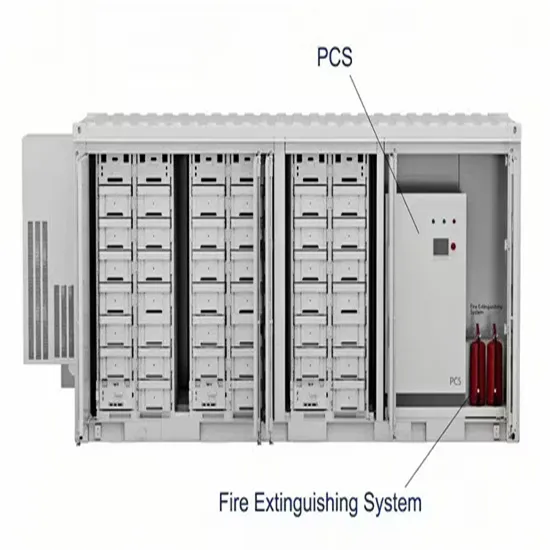

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.