Electronic transport properties in lithium cobalt oxide battery

Jun 20, 2025 · Herein, we use the Ion-Gated Transistor (IGT) configuration to study the dependence of the electronic conductivity of lithium cobalt oxide (LiCoO2 or LCO)-based

Electronic transport properties in lithium cobalt oxide battery

Jun 20, 2025 · Lithium-Ion Batteries (LIBs) are widely used for energy storage in different sectors, from portable electronic devices to electric vehicles and intermittent renewable energy (wind,

Layered lithium cobalt oxide cathodes

Mar 22, 2021 · Lithium cobalt oxide was the first commercially successful cathode for the lithium-ion battery mass market. Its success directly led to the development of various layered-oxide

ARTICLE INFORMATION SHEET (AIS) SECTION 1:

Jan 23, 2023 · EHS-AIS-1015 This Article Information Sheet (AIS) is provided as a courtesy in response to a customer request. A Safety Data Sheet (SDS) has not been prepared for these

High-Voltage and Fast-Charging Lithium Cobalt Oxide

Jun 1, 2024 · This review offers the systematical summary and discussion of lithium cobalt oxide cathode with high-voltage and fast-charging capabilities from key fundamental challenges,

Lithium Cobalt Oxide (LCO) Cathode Powder for Lithium-ion Batteries

Cobalt, which was the first transition metal to be used in a lithium-ion battery metal oxide cathode more than three decades ago, is still used in select applications (e.g., rechargeable batteries in

Thermal runaway suppression effect of water mist on 18650-cylinder

Jul 1, 2022 · Currently, the potential thermal runaway (TR) hazard of lithium-ion batteries (LIBs) has attracted widespread attention. Fortunately, water mist (WM) has proven to be an effective

Layered lithium cobalt oxide cathodes

Mar 22, 2021 · Lithium cobalt oxide was the first commercially successful cathode for the lithium-ion battery mass market. Its success directly led to the development of various

Lithium Nickel Cobalt Aluminum Oxide

NCA, or lithium nickel cobalt aluminum oxide, is defined as a battery chemistry used primarily in lithium-ion batteries, notable for its high specific energy, good specific power, and longer

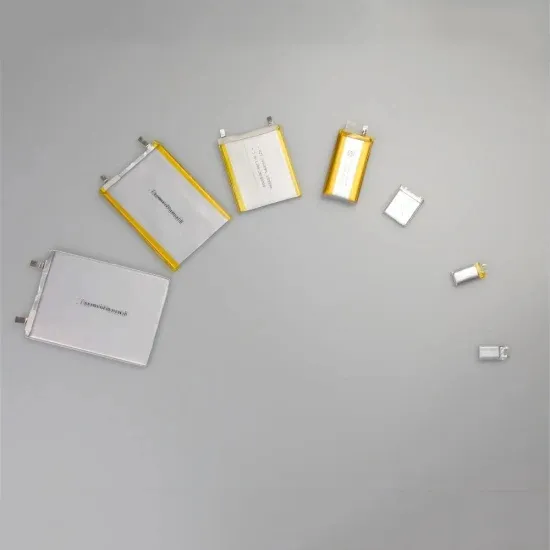

Li-po 18250 3.7V 600mAh 2.22wh Lipo Cylinder Li Ion Lithium Polymer Battery

Other attributes Application Toys, Power Tools, Home Appliances Battery Type Lithium Brand Name BELICELL Model Number LP.18250.600mah Shape cylindrical Battery Size 18*25mm

Progress and perspective of doping strategies for lithium cobalt oxide

Aug 1, 2024 · LiCoO 2 (LCO), because of its easy synthesis and high theoretical specific capacity, has been widely applied as the cathode materials in lithium-ion batteries (LIBs). However, the

A highly promising high-nickel low-cobalt lithium layered oxide

Sep 1, 2021 · Reducing cobalt dependency has attracted great interest for lithium batteries manufacturing due to limited cobalt resources and high prices. A highly

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Stabilizing the Interphase in CobaltâFree, UltrahighâNickel

1 hour ago · Realizing High Voltage Lithium Cobalt Oxide in Lithium-Ion Batteries Electrochemical Characteristics of Lithium Ion Battery Anode Materials of Graphite/SiO2 Recovery of LiCoO2

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Safety devices are very important for using any types of lithium-ion batteries because lithium is highly energetic materials and electrolyte is flammable. Therefore,

Progress and perspective of high-voltage lithium cobalt oxide

Nov 1, 2022 · Lithium cobalt oxide (LiCoO 2, LCO) dominates in 3C (computer, communication, and consumer) electronics-based batteries with the merits of extraordinary volumetric and

Lithium cobalt oxide â Knowledge and References â Taylor

Lithium cobalt oxide is a mature and proven industry-standard battery material that has been used for over 40 years due to its high stability during electrochemical cycling, high energy density,

LiCoO2: formation, structure, lithium and oxygen

May 31, 2004 · As the electrochemical properties and the electrical conductivity strongly depend on the structure of the oxide, primary attention is given to lithium cobalt oxide with defect

Stabilizing the Interphase in CobaltâFree, UltrahighâNickel

1 day ago · Realizing High Voltage Lithium Cobalt Oxide in Lithium-Ion Batteries Electrochemical Characteristics of Lithium Ion Battery Anode Materials of Graphite/SiO2 Recovery of LiCoO2

6 FAQs about [Lithium cobalt oxide battery cylinder]

Why is cobalt used in lithium ion batteries?

The use of cobalt in lithium-ion batteries (LIBs) traces back to the well-known LiCoO 2 (LCO) cathode, which offers high conductivity and stable structural stability throughout charge cycling.

What is lithium cobalt oxide?

Nature Energy 6, 323 (2021) Cite this article Lithium cobalt oxide was the first commercially successful cathode for the lithium-ion battery mass market. Its success directly led to the development of various layered-oxide compositions that dominate todayâs automobile batteries. You have full access to this article via your institution.

Can nickel replace cobalt in lithium ion battery cathodes?

Nickel (Ni) as a replacement for cobalt (Co) in lithium (Li) ion battery cathodes suffers from magnetic frustration. Discharging mixes Li ions into the Ni layer, versus just storing them between the oxide layers.

Why is layered oxide cathode the future of lithium-ion battery technology?

Although LiCoO 2 was the first material that enabled commercialization of the lithium-ion battery technology, the rapid increase in the electric vehicle market and the limited availability of cobalt are forcing the community to reduce cobalt or eliminate it altogether in layered oxide cathodes.

What is a cylindrical lithium-ion battery?

The cylindrical lithium-ion battery adopts an appropriate and mature winding process, with a high degree of automation, stable quality of the cylindrical lithium-ion battery, and relatively low cost. There are many types of cylindrical cells, such as 14650, 17490, 18650, 21700, 26650 and so on.

What are the different types of cylindrical lithium batteries?

There are many types of cylindrical cells, such as 14650, 17490, 18650, 21700, 26650 and so on. Cylindrical lithium batteries are more prevalent in Japanese and Korean lithium battery companies, and there are also companies of appropriate scale in China that produce cylindrical lithium batteries. â ¢.

Update Information

- Lithium cobalt oxide battery station cabinet cover

- Lithium battery top seal cylinder

- Lithium battery cell large single cylinder

- Amsterdam lithium battery cylinder

- Embedded lithium battery energy storage system

- RV 12v lithium battery pack

- Which company has the cheapest lithium battery in Macedonia

- Tuvalu energy storage lithium battery pack customization

- Lithium battery pack has a string of small capacity

- Lithium battery station cabinet recommendation

- Solar energy storage and control lithium battery

- Micronesia lithium battery assembly outdoor power supply

- Solomon Islands High Voltage Energy Storage Lithium Ion Battery Price

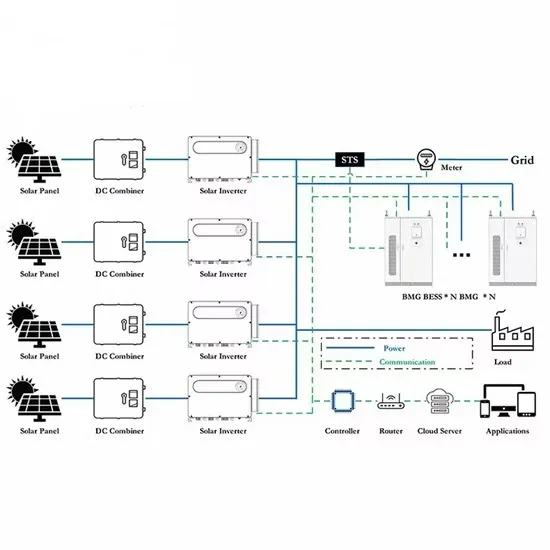

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.