4.1 Installation Environment and Clearance Requirements

Ensure that the floor or installation support can bear the weight of the UPS, batteries, and battery racks. Reserve the following clearances around the cabinet to facilitate operations and

Installation, connection and sizing of cables with UPS

Jun 22, 2022 · Ready-to-use UPS units The low power UPSs, for micro computer systems for example, are compact ready-to-use equipement. The internal wiring is built in the factory and

China Ups Battery Cabinet, Ups Battery Cabinet Wholesale,

Upgrade your Power Distribution Cabinet & Box with the elegant and durable Ups Battery Cabinet.When selecting a power distribution cabinet or box, important factors include size,

Battery cabinet installation quota

Designed for power, efficiency, and long life, Pure Lead UPS batteries add value to every data center. C&D pure lead battery technology helps cut replacement and energy costs, installation

Powerware 9315 UPS 200–300 kVA Installation Manual

Oct 9, 2024 · This manual contains important instructions that you should follow during installation and maintenance of the UPS and batteries. Please read all instructions before operating the

Installation specification for UPS battery cabinets and racks

Aug 7, 2024 · UPS battery cabinet and battery rack installation specifications. UPS battery cabinet is an intelligent power distribution cabinet that comprehensively collects all energy data for the

Eaton battery solutions brochure

Apr 15, 2025 · Eaton the globe to ensure the highest-quality batteries are easy-to-install as they do batteries are available and qualified for not require special harnesses, which use. As new

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA and 93PM 50-200kW UPS to

BC Series UPS Battery Cabinets

Jan 23, 2024 · Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To

System earthing arrangements for installations comprising UPSs

4 days ago · When batteries are not installed in a cabinet, i.e. generally in a special room, the measures presented at the end of this chapter should be implemented. Note: The TN system

PowerXpert 9395 UPS 550 kVA installation and

Feb 27, 2023 · None Required (If installing without a FI-UPM, it is recommended to leave a space of at least 915 mm (36") to accommodate a FI-UPM for future capacity upgrade. If Eaton

Eaton 9EHD UPS 20 40 kVA

Aug 24, 2024 · Battery backup protection is provide by equipping the UPS system with up to four External Battery Cabinets (EBCs) containing sealed lead-acid, maintenance-free batteries.

Eaton Power Xpert 9395

Sep 7, 2024 · The 9395 battery cabinet is designed to use with the 9395, 9395P, and 9395C. The primary difference is the 9395C uses an Under Voltage Relay instead of a Shunt Trip device to

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

Eaton 93PM Integrated Battery Cabinet-Large and Large

Mar 31, 2025 · This manual contains important instructions that should be followed during installation and maintenance of the UPS and batteries. Read all instructions before operating

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · UPS Battery Upgrade, Retrofit, and Replacement At Mitsubishi Electric, we have the products and expertise to guide you through battery and battery cabinet/rack decisions to

U-ENM00044

Feb 3, 2025 · Install the battery cabinet according to the installation drawings provided. Install the battery cabinet using adjustable leveling legs to ensure the cabinet is level and stable. Ensure

6 FAQs about [UPS battery cabinet installation quota]

Where is the UPS battery cabinet located?

The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21. If line-up-and-match installation, remove the rectangular knockout on the bottom front side of the UPS and the IBC (see Figure 15).

Where do I install a line-up and match Battery Cabinet?

Line-up-and-match battery cabinets are installed adjacent to the UPS. The recommended installation location is on the right side of the UPS cabinet as viewed from the front of the cabinet. See Figure 3 for line-up-and-match configuration views. Figure 3. Eaton 93PM 100 kW UPS and Two 93PM Integrated Battery Cabinets

How many 93pm battery cabinets can a UPS system use?

The UPS system has been evaluated for use with a maximum of four 93PM Battery Cabinets. Use of any other configuration may result in fire, death, and voiding of the warranty. Disconnect the charging source prior to connecting or disconnecting battery terminals. Determine if the battery is inadvertently grounded.

How many cabinets can be paralleled with a 93pm 100-400 kW UPS?

Up to four cabinets can be paralleled with a 93PM 100-400 kW UPS. Figure 38 shows the UPS and 93PM IBC-L or 93PM IBC-LH intercabinet interface connection onelines. Battery Detect and DC Shunt Trip wiring should be a minimum of 18 AWG. Four battery cabinets shown. Battery cabinets 5 through 8 are wired the same.

Where is the battery cabinet located?

The battery cabinet may be located to either the right or left of the UPS cabinet. The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21.

How many IBCs can be installed in a 93pm integrated battery cabinet?

Standalone IBC installations with three or four IBCs require a customer supplied external tie point and circuit breaker or disconnect between the IBCs and the UPS. Up to four IBCs can be installed in a standalone configuration. Use this procedure to wire standalone 93PM Integrated Battery Cabinets to the 93PM UPS cabinet.

Update Information

- Ups battery cabinet double row installation spacing

- UPS uninterruptible power supply host and battery cabinet size

- Does the 6kva UPS have a battery cabinet

- Paraguay UPS battery cabinet company

- Ups battery rack battery cabinet

- Why is the UPS battery cabinet charged

- Battery cabinet installation method

- The distance between the UPS head and the battery cabinet

- UPS battery cabinet daily maintenance

- Spanish cabinet battery cabinet installation energy

- Battery cabinet and distribution cabinet installation ESS power base station

- UPS battery cabinet placement requirements

- UPS battery cabinet price

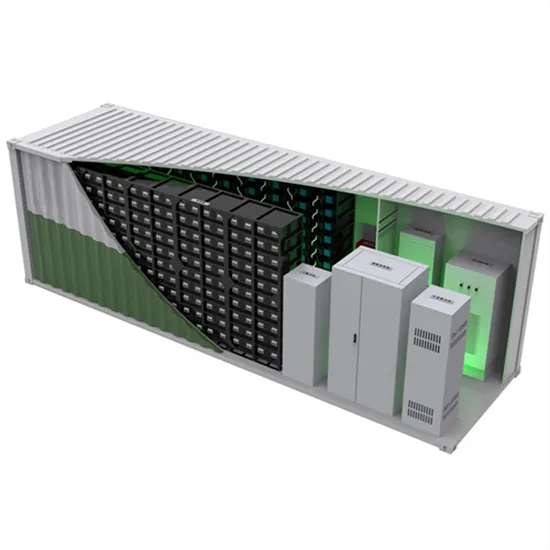

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.