Application Manual

Dec 11, 2020 · 2. Product Introduction 48 V series lithium iron phosphate battery system has been designed to provide power backup for remote or outside telecom plants like Access Terminals,

Long-Lasting 48V 100Ah LiFePO4 Battery Pack for Telecom,

Upgrade your Telecom base station, UPS system, or solar energy setup with the reliable CTECHI 48V 100Ah LiFePO4 Battery Pack. This high-performance battery offers extended lifespan,

Comprehensive Guide to Charging Solutions for Telecom Batteries

Feb 21, 2025 · Telecom batteries are essential for maintaining reliable power in communication networks. This article explores various charging solutions, including 48-volt telecom battery

48v 50ah Communication Base Station Lithium Battery | Ctechi

Oct 13, 2020 · Using standardized modular design, according to the needs of different base stations stacked battery module, power supply using BMS system management battery unit,

How to Charge a 48V Lithium Battery Without a Charger

Dec 9, 2023 · Charging a 48V lithium battery without its dedicated charger is possible through alternative methods, but it requires caution and proper knowledge. Options include using

How to charge a 48V battery (12V battery

Sep 9, 2018 · First method, unhooking and charging each battery individually? But wouldn''t I be just shorting a battery out if I tried charging one at a time while they are still wired in series.

Why choose SVC 48V Lithium iron battery for Telecom base station?

Aug 13, 2024 · In summary, SVC 48V lithium iron batteries have better performance than lead-acid batteries in terms of long cycle life, high temperature resistance, and high rate discharge,

How Do I Charge a 48V Lithium Battery Safely?

Sep 29, 2024 · Charging a 48V lithium battery safely is crucial for maximizing its performance and ensuring longevity. Following specific guidelines will help prevent damage and enhance overall

Base Station Communication Rack Mount Lifepo4 Battery 48V

High quality Base Station Communication Rack Mount Lifepo4 Battery 48V 100Ah 4.8 KWH from China, China''s leading product market rack mount lifepo4 battery 48v product, with strict

How to Charge a 48V Lithium Battery: A Comprehensive Guide

Aug 20, 2024 · To charge a 48V lithium battery, use a compatible charger rated at approximately 54.6V. Connect it properly and monitor the charging process to avoid overcharging. When it

48V 50Ah Lifepo4 communication base station battery

Professional battery manufacturer since 1995. Best lifepo4 batteries, 48V 50Ah Lifepo4 Solar Batteries communication base station battery Supplied by Shenzhen Fubangcheng Electronics

Maintenance Points for Telecom Base Station Batteries

(1) Insulating mats should be arranged in the battery pack maintenance channel. (2) Batteries of different manufacturers, capacities, and models are strictly prohibited from being used in the

48V Battery Guide: Charging, Safety and More

Jan 31, 2024 · Deep dive into implementing an effective charging method for a 48V lithium battery, which includes why 48V batteries are prevalent in battery modules, learning the correct way to

Introduction of 48V lithium battery pack for communication

Apr 13, 2021 · The lithium battery pack for the 48V communication base station provides overcharge, over-discharge, overcurrent, overtemperature, and short circuit protection, and

The Ultimate Guide to Charging a 48V Lithium

Aug 17, 2025 · Typically, a 48V lithium-ion battery should be charged within the range of 54.6V to 58.4V, depending on the charging protocol specified by the

Charging and Reviving 48V Lithium Batteries: A Guide

Aug 15, 2024 · To safely charge and revive 48V lithium batteries, you must follow precise protocols, monitor the state of charge, and avoid common mistakes. Use a compatible

NPFC Series Product Manual 48NPFC100 Lithium Battery

Nov 4, 2024 · 2. Product Introduction 48NPFC100 lithium battery pack is an advanced product developed according to the requirements of new backup power supply for communication

Solar Charge Controller MPPT 100A 12V 24V 36V 48V with

May 29, 2025 · Product Description Solar Panel Controller, Backlit LCD Display 7 Modi Multifunctional 12V 24V 36V 48V Adaptive Solar Loading Controller for The Communication

Communication Base Station Power Supply

Product Overview The 48V series lithium iron phosphate batteries adopt an integrated structural design, are equipped with the monitoring function of an intelligent battery management system

Leading 48V LiFePO4 Battery Systems for Solar, Mobility

9 hours ago · Explore why 48V LiFePO4 batteries are the top choice for solar homes, backup systems, telecom towers, and EVs in 2025. Scalable, smart, and ultra-safe energy storage.

6 FAQs about [How to charge the 48v communication base station battery]

What is the charging process for 48V lithium-ion batteries?

The charging process for 48V lithium-ion batteries involves higher voltage settings compared to lower voltage batteries. Chargers must be specifically designed for the 48V system to handle the voltage and current requirements. Additionally, the charging time may vary based on the battery’s capacity and the charger’s output.

Can a 48v battery be charged?

Chargers must be specifically designed for the 48V system to handle the voltage and current requirements. Additionally, the charging time may vary based on the battery’s capacity and the charger’s output. What are the common mistakes to avoid when charging a 48V lithium-ion battery?

How do I choose a charger for a 48V lithium-ion battery?

When choosing a charger for a 48V lithium-ion battery, ensure it matches the battery’s voltage and has a compatible charging profile. Look for features such as overcharge protection, temperature monitoring, and a Battery Management System (BMS) for optimal safety and efficiency.

How do I care for a 48V lithium ion battery?

To ensure optimal performance and longevity, follow these best practices: use a compatible charger designed for 48V lithium-ion batteries, avoid overcharging and deep discharging, and charge the battery in a well-ventilated area. Maintain a consistent charging routine and avoid exposing the battery to extreme temperatures during charging.

What is a 48V lithium battery system?

The so-called "48V" is actually the normal operating voltage of lithium-ion battery group, hence often referred to as the "48V system". In practice, however, the actual voltage is 51.2V. Compatibility: 48V lithium battery systems can typically directly replace the old lead-acid battery systems due to their similar system voltage.

How long does it take to charge a 48V 20Ah battery?

For instance: Example Calculation: A 48V 20Ah battery charged with a 5A charger would theoretically take around 4 hours to charge (20Ah ÷ 5A). However, actual charging time may be slightly longer due to the trickle charging phase at the end of the cycle, which ensures a full charge.

Update Information

- How to charge the battery of a communication base station

- Communication base station energy storage 48v battery

- How much does a flow battery for a communication base station cost

- How powerful is the battery energy storage system for the Democratic Republic of Congo s communication base station

- How to divide the DC cabinet of the battery energy storage system of the communication base station

- How much power does the battery energy storage system of a building communication base station generally have

- How much does it cost to build a communication base station lead-acid battery

- How high is the flow battery tower of the Damascus communication base station

- How to isolate the communication base station energy storage battery

- How much is the photovoltaic power generation power of the lead-acid battery of the Ottawa communication base station

- 5nm chip communication base station battery energy storage system

- Negative 48v communication base station power supply

- South Korea 5g communication base station battery energy storage system construction ESS system

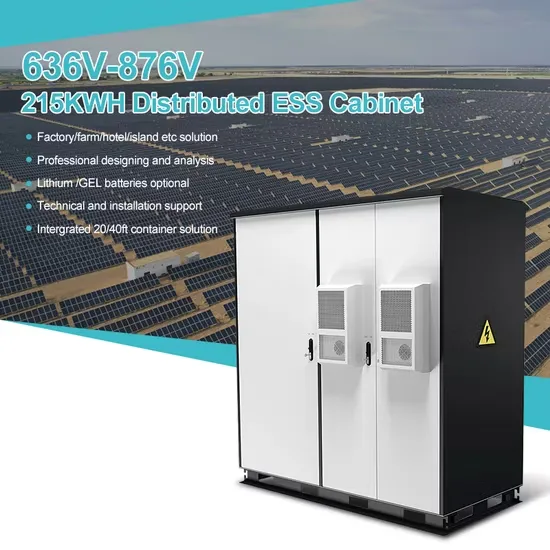

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.