Battery Energy Storage System Components and

Jul 21, 2023 · In our previous article, we have defined what an energy storage is by using parameters like SoH, EoL, battery capacity, round-trip efficiency etc.

Battery Module vs Pack: Differences for Energy

Dec 29, 2023 · Delve into the distinctions between battery modules and packs. Gain insights into performance metrics and considerations for efficient energy

Detailed Application of Energy Storage Lithium

Oct 29, 2024 · As the demand for sustainable energy solutions continues to grow, home energy storage lithium-ion battery packs stand out as effective solutions

Understanding the Components of a Battery Energy Storage

Oct 23, 2024 · 1. Battery Pack The battery pack is the heart of a battery energy storage system. It is where the electrical energy is stored and subsequently discharged when needed. Battery

Sustainable Energy Storage: LFP Batteries

Aug 22, 2024 · Lithium Iron Phosphate (LFP) battery cells have emerged as a prominent technology in energy storage systems and the integration of renewable energy production in

What Is Inside a Battery Pack for Energy Storage?

Jun 26, 2025 · 1. **Cells**: The building blocks of a battery pack are its cells. Depending on the type of battery, these cells can be lithium-ion, lead-acid, nickel-metal hydride, or others. Each

A complete analysis of battery cells, modules, battery packs and energy

In the new energy sector, battery cells, modules, and battery packs are the core components of energy storage systems. Energy storage systems are categorized into household storage,

Components of the energy storage battery pack

Converts kinetic energy into electrical energy for storage in the battery and improves efficiency: 1. Electric Motor. In an electric car, the powertrain consists of several key components,

The Key Components of Battery Energy Storage Systems (BESS)

Aug 18, 2025 · Understand battery energy storage system components and how their design impacts the efficiency and reliability of BESS including diagrams.

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Conclusion Understanding the intricate relationship between battery cells, modules, and packs is crucial for designing efficient, reliable, and high-performing energy

Working principle and application prospects of battery packs

Jan 3, 2025 · Explore the importance and advancements in battery packs, from powering electronics to energy sustainability. Discover key components, future prospects, and

Key Components of a Battery Energy Storage System & How

Mar 26, 2025 · A battery energy storage system is more than just a collection of batteries; it''s a well-designed setup that makes energy more reliable and sustainable. From the core battery

What Are the Components of the Lithium Iron Phosphate Battery Pack

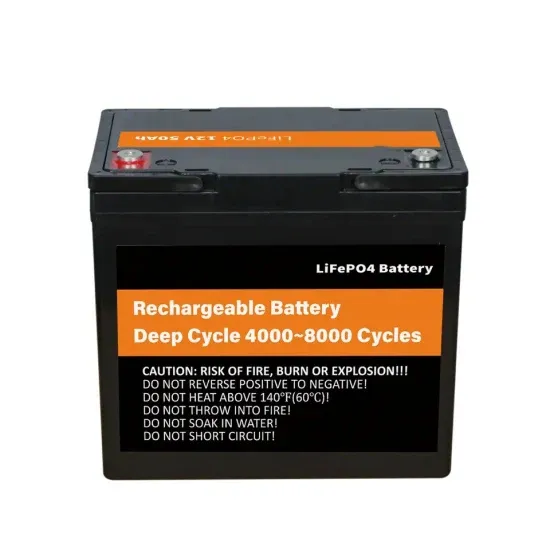

Jan 18, 2023 · Lithium iron phosphate batteries have a series of unique advantages such as high working voltage, high energy density, long cycle life, and environmental protection, and

Power Battery Basics: Cells, Modules & Packs Explained

Jan 4, 2024 · The electric vehicle and energy storage markets have been on a relentless rise, attracting an influx of newcomers and partners to the battery industry. For those transitioning

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

6 FAQs about [Components of the energy storage battery pack]

What are the critical components of a battery energy storage system?

In more detail, let’s look at the critical components of a battery energy storage system (BESS). The battery is a crucial component within the BESS; it stores the energy ready to be dispatched when needed. The battery comprises a fixed number of lithium cells wired in series and parallel within a frame to create a module.

What are the components of an EV battery pack?

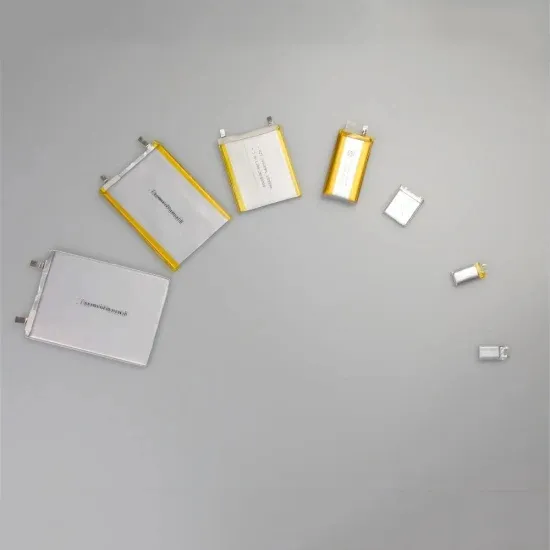

An EV battery pack comprises several key elements: Cells: The basic energy storage units, commonly cylindrical, prismatic, or pouch cells. Modules: Groups of cells arranged in series or parallel to achieve the desired voltage and capacity.

How does a battery energy storage system work?

The HVAC is an integral part of a battery energy storage system; it regulates the internal environment by moving air between the inside and outside of the system’s enclosure. With lithium battery systems maintaining an optimal operating temperature and good air distribution helps prolong the cycle life of the battery system.

Why is a battery pack important?

Its assembly involves intricate processes to ensure reliability, energy efficiency, and safety. A well-designed battery pack not only optimizes vehicle range and performance but also enhances compatibility with EV charging systems, influencing charging speed and thermal management.

What is the composition of a battery?

The composition of the battery can be broken into different units as illustrated below. At the most basic level, an individual battery cell is an electrochemical device that converts stored chemical energy into electrical energy. Each cell contains a cathode, or positive terminal, and an anode, or negative terminal.

What is battery pack assembly?

Battery pack assembly is a critical component of the electric vehicle (EV) ecosystem. The efficiency, safety, and longevity of EVs depend significantly on the quality and precision of their battery packs. Similarly, the performance of EV charging infrastructure is closely linked to the characteristics of these battery systems.

Update Information

- Ouagadougou liquid-cooled energy storage cabinet system lithium battery pack

- Energy storage cabinet battery series battery pack

- Energy storage battery pack products

- Energy storage battery pack including bms

- Outdoor Energy Storage Battery Pack

- New Delhi Energy Storage Lithium Battery Pack Manufacturer

- Agent for home energy storage battery pack

- Lithium-ion battery pack energy storage

- Ultra-large battery sodium-ion energy storage cabinet

- South Korea 5g communication base station battery energy storage system construction ESS system

- Kenya New Energy Battery Storage Box Company

- Energy storage battery manufacturing in India

- Tripoli emergency power supply energy storage battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.