SUPERSEDEDconventional central inverters.

Jul 27, 2023 · A study conducted by 3rd party engineering firm Solvida compared three inverter solutions: 600V central inverters, 1000V string inverters and SolarEdge''s 3-phase commercial

On the sizing of PV inverters with reactive power capability

Sep 1, 2023 · The high penetration of grid-tied photovoltaic (PV) systems interfaced by power electronic converters can affect the power system. In this scenario, conventional PV inverters

Microinverter recommendation for 72-cell panels

Mar 18, 2016 · Looks like not much experience on this board with 72-cell panels combined with Microinverters. Are there any members that have chosen 72-cell panels for residential systems

⚡ "What''s the Difference?" — A Smart Guide to 60-Cell vs. 72

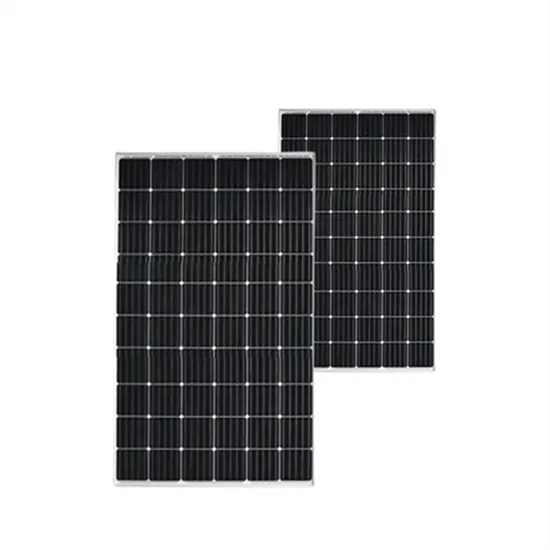

Jun 1, 2025 · 60-cell panels are better suited for smaller string inverters and microinverters due to their lower voltage. Efficiency per cell is similar, but 72-cell panels produce more power due to

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The advanced functionalities can be accomplished by using diversified and multifunctional inverters in the PV system. Inverters can either be connected in shunt or series

60 cells or 72 cells solar panel: Which is better?

Dec 31, 2021 · In addition, the MPPT technology makes it possible to connect any solar panel such as 60 cells or 72 cells to charge even 12 volts battery bank

Inverter Power Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · Yes, by knowing the inverter power and battery capacity, you can estimate how long the inverter will run on the battery under a specific load. This calculator streamlines the

Enphase Inverters together

Apr 10, 2020 · Does anyone know if I can mixed IQ7Plus and IQ7X inverters together? I have one Enphase X-IQ-AM1-240-3 M combiner box and only 4 panels with IQ7Plus inverters today. I

Solar Panels: 60 vs. 72 Cells | AltE Store

Other than the obvious difference of 12 solar cells, there are pros and cons to using 60 and 72 cells in different solar power systems. First a little background. Solar panels are made from

Connect new IQ8A-72-2-US microinverter system (1 string)

The load center (subpanel) connects to 2 existing M250-60-2LL-S22 (2 strings). The M250 strings are monitored by an Envoy S (outlet plug in house near the load center). Can the new IQ8A-72

Choose the Perfect Solar Panel: 60 vs 72-Cell Complete Guide

Apr 7, 2020 · However, both 60-cell and 72-cell solar modules use the same cell technology, and they work out to the same price from a cost-per-watt perspective. Either option can be used in

Looking to swap to higher wattage panels with old Enphase

May 19, 2022 · Last year I added-on 4 more used (260W REC) panels/microinverters/racking extensions for a cost of $1.22/watt (not including my DIY labor). Now I''m trying to figure out if

Review and Classification of Control Systems in Grid-tied Inverters

May 1, 2017 · The major advantages and disadvantages of these parameters are highlighted and compared. Then, the most important characteristics of these parameters are presented in a

Five Ways to Mix and Match Solar Panels

Jun 21, 2020 · However, you will need to check the datasheet if you''re planning on mixing 60-cell solar panels with 72-cell solar panels in the same string. Power optimisers let you mix and

60-Cell vs 72-Cell Solar Panels: Everything You Need to Know

Mar 19, 2024 · When you''re purchasing solar panels, you might also be asked whether you want a 36-cell, 60-cell, 72-cell, or 144-cell panel, and whether you need a 12V or 24V solar panel.

New Install 72Cell Panels with a mix of SolarEdge P320/P400

Jul 31, 2019 · System is SolarEdge SE500H Inverter16 Jinko JKM310P-72 panels (310W) but the report says they used 3 different micro inverters (1) P400-5NC4ARM-NA21 (12) P320

Parallel Inverters

Jun 6, 2019 · The user disconnected the generator, removed all loads, switched off the inverter, switched off PV and switched off battery - then reversed the process switching all back on

Review of multilevel voltage source inverter topologies and

Feb 1, 2011 · In this study, the most common multilevel inverter topologies and control schemes have been reviewed. Multilevel inverter topologies (MLIs) are increasingly being used in

60-Cell vs. 72-Cell Solar Panels: Which One''s Best?

Jun 14, 2018 · What''s the difference between 60-cell and 72-cell solar panels? The summary: 72-cells are about a foot taller, and they cost a bit less to mount in large-scale applications.

4 FAQs about [Can the 72 of the 60 inverter be used ]

Are 60-cell and 72-cell solar panels the same?

However, both 60-cell and 72-cell solar modules use the same cell technology, and they work out to the same price from a cost-per-watt perspective. Either option can be used in residential or commercial installs – the ideal choice depends on your array layout and space constraints where you will mount your system.

What if 24V 72-cell solar panels were used in cold environments?

If they were using 24V 72-cell solar panels, they would be limited to only 16 pieces (1000/49.5/1.21=16) in series in cold environments. The second change was still in the battery based world, with solar charge controllers that are used to manage to put the power from the PV panels into the batteries.

How many volts does a 72 cell solar panel produce?

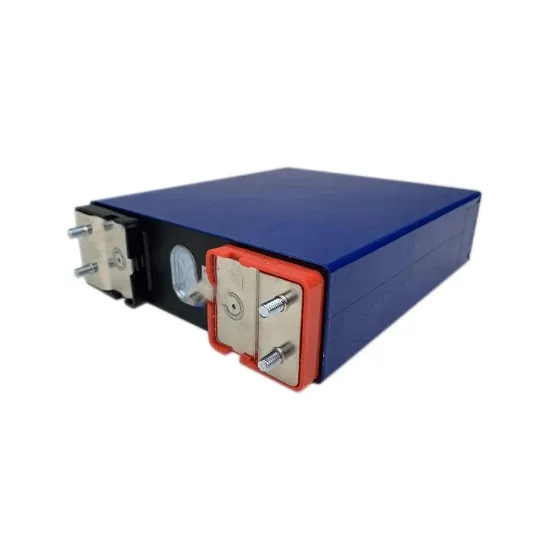

A 72-cell solar panel produces 36 volts and is good for charging 24 volts better hence it is called having a nominal voltage of 24 volts. Earlier, solar panels were used for off-grid solar power systems where their main purpose was to charge the batteries. Therefore, manufacturers use to design solar panels based on battery voltage.

How do micro-inverters work?

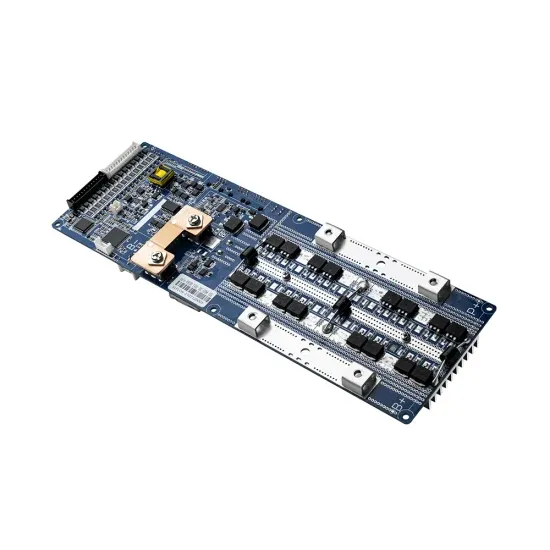

Micro-inverters work on a 1-to-1/2/4 system, where each inverter is hooked up to an individual PV panel (or 2 panels, sometimes 4 panels). The benefit of this type of system is that it is modular: if one part stops working, it doesn’t affect the rest of your array.

Update Information

- 72 volt with 60 volt inverter

- How many hours can a 24v inverter 2000w be used for

- Can the inverter be used as a battery

- What communication base station inverter is used in Montevideo

- Three-phase inverter is widely used

- Can a 12V inverter be used with a 60V one

- Can the 96V industrial frequency inverter be used at home

- Can the smart inverter be used with 98vf batteries

- What kind of inverter is used for 48v

- Which battery can be used with inverter

- Lithium battery 72 volt 6000w inverter

- What kind of battery can be used with the inverter

- Can 60v220 inverter 48v be used

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.