HUAWEI VR Glass如何安装使用PCVR助手 | 华为官网

华为官网提供手机、平板、笔记本、智慧屏、智能穿戴等产品常见故障问题解答和使用技巧, 查看更多''HUAWEI VR Glass如何安装使用PCVR助手''相关信息.

Global and China Photovoltaic Glass

May 21, 2019 · Globally Globally, more more than than 90% 90% of of crystalline crystalline silicon silicon PV modules use the China-made PV glass. Many a foreign player like AGC has

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Classification of Solar Photovoltaic Glass_PV machine

The most widely used solar photovoltaic glass today is high transmittance glass, which is a glass with low iron content, which is commonly known as ultra-white glass. Iron is an impurity in

HUAWEI Vision Glass

HUAWEI Vision Glass官方渠道售卖!华为商城提供最新款的HUAWEI Vision Glass的价格、参数、图片等信息。官方品质保证,欢迎选购!特别提醒: ※以上页面中的产品图片及屏幕内容

Global and China Photovoltaic Glass

May 21, 2019 · In price''s terms, PV glass price in China presented a choppy downtrend in the first half of 2018, and even nosedived after the launch of "531" 531 Policy Policy. In In July July

HUAWEI Vision Glass 智能观影眼镜

【HUAWEI Vision Glass 智能观影眼镜】官方渠道售卖!华为商城提供最新款的【HUAWEI Vision Glass 智能观影眼镜】的价格、参数、图片等信息。官方品质

Classification of solar photovoltaic glass

The most widely used solar photovoltaic glass today is high transmittance glass, which is glass with low iron content, which is commonly known as ultra-clear glass. Iron is an impurity in

Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Demand for solar photovoltaic glass has surged due to growing interest in green energy. This article explores types like ultra-thin, surface-coated, and low-iron glass used in

The difference between photovoltaic glass and ordinary glass

Jun 16, 2025 · Photovoltaic glass usually uses ultra-white glass, which has a higher technical threshold than ordinary glass. The strength and transmittance of photovoltaic glass directly

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

What is the difference between photovoltaic glass and ordinary glass

Apr 20, 2022 · Technically speaking, photovoltaic glass has high requirements for photovoltaic transmittance, mechanical strength, corrosion resistance, oxidation resistance, high

Solar Glass Manufacturers in India | Solar Panel

Feb 23, 2025 · Elevate your solar panels with our anti-reflective coated solar glass. Connect with leading solar glass manufacturers in India for detailed

Introduction to deep processing of photovoltaic glass_Sinoy

The deep processing process of photovoltaic glass includes two steps: tempering and coating. Tempering aims to enhance the strength of the glass, while coating is to coat a layer of anti

Crystalline PV Glass VS. Amorphous Silicon PV

Oct 28, 2022 · Solar photovoltaic glass is a kind of special glass that can use solar radiation to generate electricity by laminating into solar cells and has

Visual and energy optimization of semi-transparent

Under EN 17037, photovoltaic glass shows a slightly lower luminous irradiance than ordinary glass, at 41.9 %, but meets the minimum glare threshold in the glare analysis for 100 % of the

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · The bending strength of toughened glass is 3 ~ 5 times of that of ordinary glass, and the impact strength is 5 ~ 10 times of that of ordinary

6 FAQs about [Huawei ordinary glass photovoltaic glass]

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

Which glass is used in photovoltaic power generation?

The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass. HHG is a professional glass manufacturer and glass solution provider include range of tempered glass, laminated glass, textured glass and etched glass.

What is a 3.2mm glass solar cell?

At present, the mainstream product in the market is 3.2mm ultra white photovoltaic glass, with solar cell spectral wavelengths ranging from 320 to 1100 nanometers, and solar transmittance reaching up to 91% to 92%. Can be used as a packaging board for crystalline silicon solar modules.

Can glass be used for solar energy?

The initial development and utilization of solar cells using glass, soon gained attention from countries like the United States and Japan, thereby accelerating the research, development, and application of low-iron, ultra-thin glass for solar energy purposes. Demand for solar photovoltaic glass has surged due to growing interest in green energy.

What is ultra white Photovoltaic Glass?

Ultra white photovoltaic raw glass can be processed into ultra white photovoltaic processed glass through tempering process, which can achieve ideal mechanical strength to resist adverse weather conditions and other factors of damage. During the tempering process, an anti reflective coating can be added to improve efficiency. (3) TCO glass

Update Information

- Huawei photovoltaic glass processing factory

- Huawei photovoltaic glass name

- Huawei s photovoltaic glass brand in New York USA

- Bulgarian thin film photovoltaic module glass

- Berlin electric heating photovoltaic glass

- How much electricity does photovoltaic glass generate per square meter

- Photovoltaic glass oblique stripes

- The latest rumors about photovoltaic glass

- Photovoltaic glass level

- 2mm solar photovoltaic glass

- High calcium stone for photovoltaic glass

- Architectural Photovoltaic Laminated Glass

- Huawei photovoltaic solar panels are all brands

Solar Storage Container Market Growth

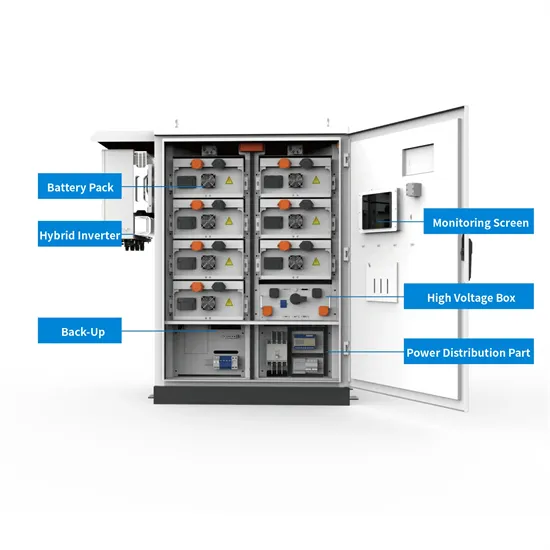

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.