Photovoltaic panels: new rules for assessment of

Jul 7, 2025 · JRC scientists have put forward a set of rules for calculating the carbon footprint of photovoltaic (PV) modules. The proposal will inform the

Design and Simulation of a 10MW Grid-Connected PV

May 20, 2019 · Abstract The main goal of this final master thesis is to design and make a comparative analysis of two different solar cell technologies (monocrystalline solar cell and

Trina Vertex Solar Panels 435W 500W 550W 600W 670W Monocrystalline

Dec 21, 2024 · Trina Vertex Solar Panels 435W 500W 550W 600W 670W Monocrystalline Silicon Photovoltaic Solar Power Panels PV Module EU Stock, Find Details and Price about Solar

Extraction of Monocrystalline Silicon Photovoltaic Panel

Oct 12, 2023 · In this approach, the five parameters that are necessary for the characterization and identification of the PV module are: short-circuit current, open circuit voltage, ideality factor

Western European monocrystalline photovoltaic module panels

A monocrystalline PV panel is a premium energy-producing panel consisting of smaller monocrystalline solar cells (60 to 72 cells). Their superior aesthetics and efficiency make them

Combining offshore wind and solar photovoltaic energy to

Apr 1, 2022 · In Europe, however, the high penetration of offshore wind brings intermittency and power variability into the existing power grid. Offshore solar photovoltaic power is another

A Detailed Performance Model for Photovoltaic Systems

Oct 2, 2013 · The versatility of the model lies in its accurate prediction of the aforementioned criteria for panels of different types, including monocrystalline and polycrystalline silicon. The

Analyze and Study on Photovoltaic Parameters of Mono-Crystalline

Dec 27, 2019 · The main purpose of this study is analyzing the parameters variation of the PV panel under various values of temperature and irradiation to discuss their effect

Experimental analysis of innovative perforated heat sinks for

Jan 1, 2025 · The monocrystalline silicon photovoltaic panels analyzed will be referred hereinafter as photovoltaic (PV) panels. The basic concept of the analysis was the designing and testing

Analysis of specifications of solar photovoltaic panels

May 1, 2022 · The use of photovoltaic power plants is rapidly expanding, despite the continued growth in the production of traditional mineral resources. This paper analyses photovoltaic

Comparison of different physical models for PV power

Sep 1, 2015 · Finally, (Celik and Acikgoz, 2007)) compared four- and five-parameter analytical models to calculate the operating current of a 120 W monocrystalline photovoltaic module

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Difference Between Monocrystalline, Polycrystalline, and Thin-Film Solar Panels. Comparison Between Various Types of Solar Panels & Which

Impact of Temperature on the Efficiency of Monocrystalline

Dec 2, 2024 · The interventions into the manuscript according to your observations are highlighted with orange. Please find attached our responses to your observations: The manuscript

Parameter estimation of solar photovoltaic (PV) cells: A review

Aug 1, 2016 · A detailed discussion about the characteristics of PV cell model parameter estimation problem, estimability and identifiability of the model parameters of PV cells is

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Monte Carlo prediction of the energy performance of a photovoltaic

Jan 1, 2024 · A typical monocrystalline silicon panel is composed of five layers — photovoltaic cells made of silicon which are encased in two EVA layers, a front layer of glass and a plastic

A Study of the Temperature Influence on Different

Jun 16, 2021 · The results show that the temper-ature has a significant impact on the various parameters of the photovoltaic panel and it controls the quality and performance of the solar

Assessing the carbon footprint of photovoltaic modules through the EU

Jun 1, 2023 · The rapid deployment of renewable energy and PV is at the core of the REPowerEU plan – the EU initiative to put an end to its dependency on Russian fossil fuels. By the end of

Theoretical and Real Efficiency of Monocrystalline PV

May 14, 2019 · Based on the data collected regression models have been developed that explained changes in the amount of electric energy generated in monocrystalline PV modules,

Facilitating circularity of end-of-life photovoltaic in China

May 16, 2025 · The rapid growth of global photovoltaic (PV) installation will lead to the emergence of end-of-life (EoL) modules in the coming decades. It is essenti

Advancements in cooling techniques for enhanced efficiency

Apr 1, 2025 · Advancements in cooling techniques for enhanced efficiency of solar photovoltaic panels: A detailed comprehensive review and innovative classification

6 FAQs about [Detailed parameters of Western European monocrystalline photovoltaic panels]

How much power does a monocrystalline photovoltaic panel produce?

Monocrystalline photovoltaic panels have an average power ranging from 300 to 400 Wp (peak power), but there are also models that reach 500 Wp. The purity of silicon in these monocrystalline panels guarantees reliable energy production even in conditions of reduced sunlight.

What is the difference between polycrystalline and monocrystalline photovoltaic panels?

From the point of view of extrinsic characteristics: Polycrystalline panels are variegated blue and show a more disordered structure. Monocrystalline photovoltaic panels have an average power ranging from 300 to 400 Wp (peak power), but there are also models that reach 500 Wp.

What is a monocrystalline solar panel?

The monocrystalline panel represents one of the most advanced technologies in the field of solar panels. Its main characteristic lies in the use of a single silicon crystal, hence the term monocrystalline. This crystal is extracted from a larger block of silicon through a sophisticated process that ensures a high degree of purity.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels offer a series of advantages. Thanks to their high degree of silicon purity, they are considered the most efficient. The efficiency rate, which measures the amount of solar energy converted into electrical energy, usually ranges between 12% and 19%.

What are the parameters of a BP Solar PV panel?

The parameters in Table 2 have an explicit physical meaning intrinsic to a specific PV panel. Figure 4 presents the model V-I curves for BP Solar’s BP 3 Series 235 W panel at a cell temperature of 25◦C and solar irradiation at five levels: 1000 W/m2; 800 W/m2; 600 W/m2; 400 W/m2; and 200 W/m2 .

Can Lambert W-function extract electrical parameters of photovoltaic panels?

This paper proposes a new approach based on Lambert W-function to extract the electrical parameters of photovoltaic (PV) panels. This approach can extract the optimal electrical characteristics of the PV panel under variable conditions of irradiation and temperature.

Update Information

- How to choose monocrystalline photovoltaic panels

- Basic parameters of photovoltaic panels

- Minsk monocrystalline photovoltaic panels power generation

- Cambodia monocrystalline silicon solar photovoltaic panels

- What is the difference between monocrystalline photovoltaic panels and bicrystalline panels

- St Lucia Monocrystalline Photovoltaic Panels

- Huawei Portugal monocrystalline photovoltaic panels

- Tuvalu monocrystalline photovoltaic panels low price direct sales

- Will monocrystalline photovoltaic panels deform

- What is a Western European photovoltaic inverter

- Western European island photovoltaic panel manufacturers

- Palestinian monocrystalline photovoltaic module panels

- 6 100w monocrystalline photovoltaic panels in parallel

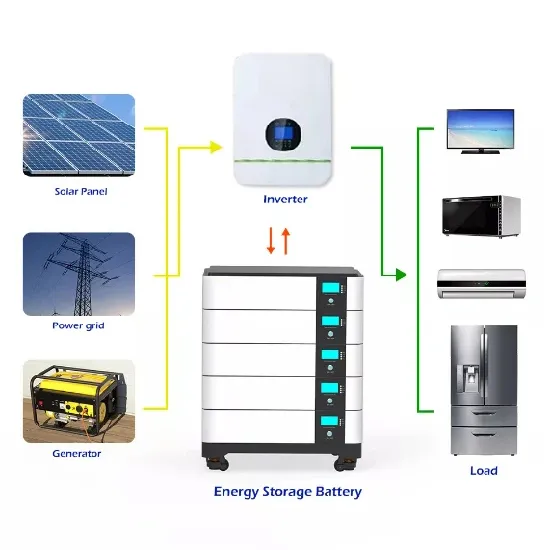

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.