Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

New Energy Battery Module Pack Assembly Line | SENFENG

New Energy Battery Module Pack Assembly Line This module pack assembly line is modular-based and compact in structure. Due to its intelligent management, it is totally traceable.

New Energy Lithium Battery Assembly Process

This article will introduce the whole assembly process of new energy lithium battery in detail, including raw material preparation, cell assembly, module assembly, battery pack test and

Battery Lab Machine,Battery Material,Battery Pack Assembly

ACEY is a high-tech enterprise and has been dedicating to designing,R&D and producing Battery Lab Machine,Battery Pack Assembly Machine and Battery Materials for over 10 years

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

China Battery Pack Assembly Line, Battery Pasting Machine

Aug 13, 2025 · ACEY New Energy Technology, founded in 2009, is a one-stop supplier specialized in manufacturing advanced machineries and offering the best tailored solutions for

Prospects of battery assembly for electric vehicles based on

Oct 4, 2023 · Abstract The ceiling of energy density of batteries in materials level motivates the innovation of cell, module and pack that constitute the battery assembly for electric vehicles

Prismatic Battery Pack Assemble Line Manufacturer, Battery

Shenzhen Bluesea Intelligent Manufacturing Technology Co., Ltd., founded in 2016, is an overall intelligent manufacturing solution supplier focusing on the research and development,

The EV Battery Manufacturing Process: Step by

Jun 5, 2024 · The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Battery Pack Assembly Process Series 7

Jun 6, 2025 · Whether it is used for new energy vehicles or energy storage scenarios, the core function of the battery pack is to store energy. "If the battery pack is compared to a soldier in

Optimization design of battery bracket for new energy

Jun 12, 2024 · As a consequence, it is particularly imperative to undertake lightweight design optimization for the battery bracket of new energy vehicles by applying 3D printing technology.

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Introduction Energy storage market is on rise across the world. Every company, new or old, that is in the field of renewables or electric vehicles, is looking for even more

New Energy Battery Assembly-WEBEN SMART

Can meet the many types of PACK flexible assembly of mixed production needs, with small batch, high flexibility characteristics; Configuration of high-precision, flexible with the tray, to meet the

New Energy Li-Ion Battery Pack Assembly: 5 Essential Steps

Aug 14, 2025 · At its core, a new energy li-ion battery pack assembly consists of multiple lithium-ion cells grouped together to create a powerful energy storage unit. These battery packs are

6 FAQs about [New Energy Pack Battery Assembly]

What is battery pack assembly?

Battery pack assembly is a critical component of the electric vehicle (EV) ecosystem. The efficiency, safety, and longevity of EVs depend significantly on the quality and precision of their battery packs. Similarly, the performance of EV charging infrastructure is closely linked to the characteristics of these battery systems.

What is a battery pack?

Battery packs will increasingly incorporate features tailored for ultra-fast charging and wireless charging technologies, driving innovation in both EVs and EV charging networks. Battery pack assembly is at the heart of the EV revolution, shaping the performance, safety, and sustainability of electric vehicles.

Who is Acey new energy technology?

ACEY New Energy Technology, founded in 2009, is a one-stop supplier specialized in manufacturing advanced machineries and offering the best tailored solutions for lithium-ion battery pack assembly line. Our R&D team has more than 20 engineers and over 10 years of professional development experience in lithium ion battery pack assembly line.

What are the components of an EV battery pack?

An EV battery pack comprises several key elements: Cells: The basic energy storage units, commonly cylindrical, prismatic, or pouch cells. Modules: Groups of cells arranged in series or parallel to achieve the desired voltage and capacity.

Why is battery pack assembly important?

A well-designed battery pack not only optimizes vehicle range and performance but also enhances compatibility with EV charging systems, influencing charging speed and thermal management. Battery pack assembly plays a pivotal role in ensuring the sustainability of electric vehicles by enabling recycling and reuse, thus reducing environmental impact.

What are modular battery packs?

Modular battery packs offer flexibility and ease of replacement, enhancing the longevity of electric vehicles and reducing lifecycle costs. Increased focus on using recyclable and eco-friendly materials will further align battery pack assembly with the goals of a circular economy.

Update Information

- New Zealand high voltage energy storage lithium battery assembly

- Peru new energy battery pack module design

- Base station new energy battery pack

- New Energy Lithium Battery Module Pack

- New Delhi Energy Storage Lithium Battery Pack Manufacturer

- Egypt lithium battery pack assembly equipment

- Battery cabinet for Seoul New Energy

- Iran 2025 new energy storage battery

- Does the new energy battery cabinet also have telecom

- New Energy Battery Cabinet Query

- New Energy Lithium Battery Solar Energy Storage

- New field energy storage battery

- Liechtenstein New Energy Battery Cabinet

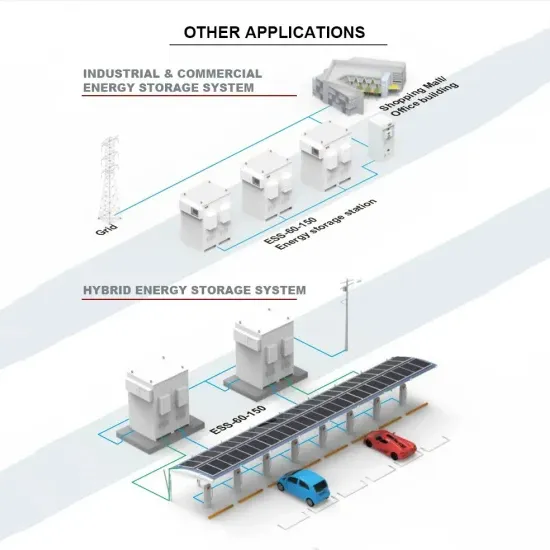

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.