llvd & BLVD in Base Station Power Cabinets

The base station power cabinet is a key equipment ensuring continuous power supply to base station devices, with LLVD (Load Low Voltage Disconnect) and BLVD (Battery Low Voltage

Base station operation guidelines

Jul 23, 2025 · If semi-permanent or permanent operation is required, however, the modular receiver delivers significant advantages. Base station setup guidelines For good performance,

Westinghouse Parts Business MG Set Control Power Cabinets

Jul 23, 2021 · The MG Control Power Cabinets replace aging and high-maintenance rotating machinery with a modern design. This design includes advanced diagnostic capabilities,

Why a Power and Environmental Monitoring System Matters for Base Stations

Apr 23, 2025 · Discover how a Power and Environmental Monitoring System ensures uninterrupted operation, optimal conditions, and security for telecom base stations. Learn why

Can You Replace the Battery in a Portable Power Station?

Jul 20, 2025 · Yes, you can replace the battery in most portable power stations—but the process isn''t always simple. Portable power stations are lifelines for camping trips, emergencies, and

Energy storage system of communication base station

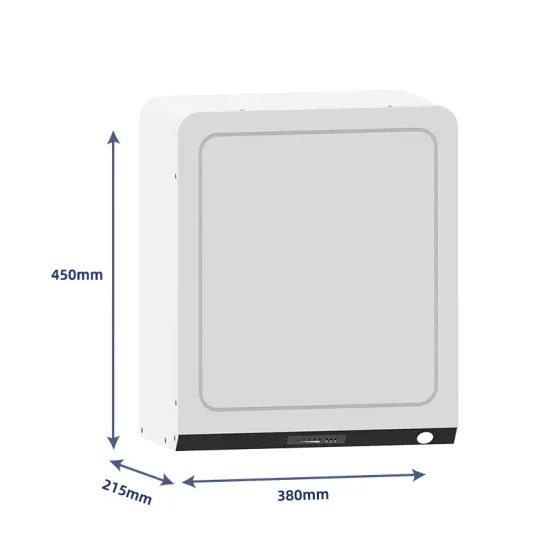

Base station energy cabinet: floor-standing, used in communication base stations, smart cities, smart transportation, power systems, edge sites and other scenarios to provide stable power

Dynamic Power Management for 5G Small Cell Base Station

Jan 9, 2021 · 5G networks with small cell base stations are attracting significant attention, and their power consumption is a matter of significant concern. As the increase of the expectation,

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · A multi-base station cooperative system composed of 5G acer stations was considered as the research object, and the outer goal was to maximize the net profit over the

এলএলভিডি & BLVD in Base Station Power Cabinets

The base station power cabinet is a key equipment ensuring continuous power supply to base station devices, with LLVD (Load Low Voltage Disconnect) and BLVD (Battery Low Voltage

New Energy Station: How to Change Energy Supply Mode

Sep 26, 2024 · Pole Mounted Energy Cabinets can be installed on existing utility poles to provide localized power supply without the need for extensive infrastructure changes. This not only

Incorrect "Power Outage" notification | SimpliSafe Support

Feb 15, 2023 · Hi @roccoscan, Have you tried pulling down on the home screen of the SimpliSafe mobile app? This will gather the latest status from your system and should clear

TETRA MTS1 Base Station Specification Sheet

Apr 5, 2025 · KEEPING COSTS DOWN The running costs of base station sites typically account for a significant portion of the total cost of ownership of any TETRA network. MTS1 base

How to Maintain Backup Power Supply for Telecommunications Base Stations?

By following these maintenance practices and implementing robust monitoring and testing procedures, telecommunications operators can ensure the reliability and effectiveness of

Machine learning for base transceiver stations power failure

Dec 1, 2024 · The widespread deployment of cellular networks has improved communication access, driving economic growth and enhancing social connections across diverse regions.

Management and maintenance of base station

Dec 11, 2024 · This article focuses on the three parts of switching power supply: "types and usage scenarios, configuration principles and algorithms, and daily

6 FAQs about [Replace the power cabinet without power failure in base station]

What is the operation and maintenance of a gu co-Cabinet base station?

Solution Guide 8 Operation and Maintenance Operation and Maintenance About This Chapter The operation and maintenance of the 3900 series GU co-cabinet base stations mainly involve alarm management, inventory management, routine maintenance, emergency maintenance, and software upgrade.

What should I know before connecting the power supply?

Before connecting the power supply, ensure that electrical connections are correct. the transformer station. component documentation, is used by default.

Why is my transformer station not working?

of the transformer station. Incorrect settings may affect the transformer station operation and cause it to conflict with the local certification. Comply with local laws and regulations when operating the transformer station. Before connecting the power supply, ensure that electrical connections are correct. the transformer station.

What is the procedure for commissioning GBTS Gu co-Cabinet base station?

The procedure for commissioning the GBTS part of the GU co-cabinet base station is the same as that for commissioning the GSM-only base station. GBTS and the NodeB on their counterpart. 7.3 Site Maintenance Items Site maintenance for the GBTS part of the 3900 series GU co-cabinet base stations is the same as that for the GSM-only base station.

What should you not do on a transformer station?

Do not scrawl, damage, or block any warning label on the transformer station. Do not scrawl, damage, or block any nameplate on the transformer station. prevent unauthorized personnel from entering. caused by misoperations. When heavy objects are being hoisted, do not walk below the cantilever or the objects.

What do you do if a power supply is energized?

to the grid. and meet specifications. to cut the power supply if people may contact energized components. within the rated voltage range. emitting equipment to prevent damage to the insulation layers of cables. Route and bind signal cables and strong-current cables or high-voltage cables separately.

Update Information

- Features of the uninterruptible power supply energy storage cabinet in the base station room

- Equipment room battery cabinet ESS power base station

- Base station combined power distribution cabinet installation

- Base station power storage cabinet

- Base station outdoor power station cabinet

- 5g base station power distribution cabinet work

- Battery cabinet base station power generation analysis

- Chad Base Station Power Distribution Cabinet

- Barbados Base Station Power Cabinet Manufacturer

- High power battery cabinet base station energy

- New Energy Battery Cabinet Base Station Power Structure

- How to connect the bridge to the battery cabinet ESS power base station

- North Africa outdoor base station power cabinet source manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.