Advancements and challenges in solar photovoltaic

Jan 1, 2025 · Given the current state of sustainable, clean energy, most researchers are concentrating on alternative energy resources. Solar photovoltaic (PV) has become especially

INSTRUCTIONS FOR PREPARATION OF PAPERS

May 9, 2023 · Solar PV arrays are susceptible to large amounts of energy losses, due to partial shading. Partial shading is caused by light barriers like trees, chimneys, roof obstructions,

Photovoltaic systems

Feb 25, 2016 · In order to use solar electricity for practical devices, which require a particular voltage or current for their operation, a number of solar cells have to be connected together to

Photovoltaic String Protection: Keeping the Current Flowing

5 days ago · Photovoltaic String Protection: Keeping the Current Flowing Safely Photovoltaic 1500V d.c. systems With the PV String protection, we have in mind the protection of PV

2023 Update: How to Calculate PV String Size — Mayfield

Nov 15, 2023 · Too many modules on a string will exceed the maximum input voltage and damage the inverter or, worse, start a fire. If too few modules are on a string, the inverter might

Comparative Analysis and Outlook of Centralized, String,

Dec 17, 2024 · Abstract. With the rise of renewable energy, optimizing photovoltaic (PV) inverter topologies— centralized, string, and micro inverters—is crucial for enhancing solar power

Understanding Solar PV Strings: A Guide for Homeowners

Aug 1, 2024 · This blog will cover the essentials of solar PV strings, including how the number of panels on a string is calculated, the importance of startup and maximum DC voltage range,

Grid-connected photovoltaic power systems: Technical and

Jan 1, 2010 · Traditional electric power systems are designed in large part to utilize large baseload power plants, with limited ability to rapidly ramp output or reduce output below a

A data-driven photovoltaic string current mismatch fault

Nov 1, 2022 · This paper investigates and collects the data of mismatched PV strings in an actual PV plant, and further the fault characteristics of mismatched PV strings are extracted through

Inspection and condition monitoring of large-scale photovoltaic

Jun 1, 2022 · To identify these invisible types of faults, two main methodologies are used; manual electrical testing, such as current–voltage (IV) curve analysis at module and string level, and

Accurate String Measurements for Solar PV Power Plants

Mar 7, 2022 · Standard Solar panels for large-scale ( 1 MW and above) are generally constructed by 156 x 156 mm (6" x 6") standard solar cells with 60 cells in one module and have three

Solar panel wiring basics: How to wire solar panels

5 days ago · Discover all the solar panel wiring basics from terms, to sequence of operations, you''ll discover everything you need to know to wire solar panels.

An effective method for detection and location estimation of

Jul 15, 2024 · The prolonged undetected electrical faults in large-scale solar photovoltaic (PV) arrays are the main cause of fire hazards. In this paper, an effective method is proposed for

Solar Inverter String Design Calculations

Oct 12, 2023 · In each string the connected solar panels should be within 4-20 modules. Since the best MPPT voltage of three phase inverter is around 630V (best MPPT voltage of single phase

Improved modelling of bypass diodes for photovoltaic applications

Aug 1, 2022 · Photovoltaic (PV) systems require bypass diodes to protect PV modules from operating at negative voltages, thus avoiding the degradation of a PV array under partial

Power loss due to soiling on solar panel: A review

Jun 1, 2016 · The characteristics of a PV module can be demonstrated by power–voltage or current–voltage curves. Fig. 1 shows the power–voltage curve of a PV module for different

Understanding Solar PV Strings: A Guide for Homeowners

Aug 1, 2024 · A solar PV string is a series of solar panels connected in a sequence to form a circuit. The panels in a string are connected by their positive and negative terminals, creating a

Is the photovoltaic panel string current constant

Each new panel added to a series of panels increases the string''''s overall voltage (V), while the current (I) in the string stays constant. The fact that a darkened panel might limit the current

Understanding PV Arrays and PV Strings: Key

Apr 15, 2025 · the difference between PV strings (a series of panels) and PV arrays (a combination of multiple strings) is critical to designing efficient solar

6 FAQs about [The main string current of photovoltaic panels is large]

What is a solar PV string?

A solar PV string is a series of solar panels connected in a sequence to form a circuit. The panels in a string are connected by their positive and negative terminals, creating a single path for the electric current. The number of panels you can have on a string depends on several factors, including:

How many solar panels per string?

Min Panels per String = 200 / 30 = 6.67 Rounding up, the minimum string size is 7 panels. Understanding the intricacies of solar PV strings, including how to calculate the number of panels per string and the importance of startup and maximum DC voltage range, is essential for optimising your solar power system.

What is a solar panel string?

Each series of these solar panels connected together is termed a solar panel string. Specific types of connectors and cables are used for wiring solar panels. These are some of the main components that maintain the efficiency of the system. Different types of wires included are as follows:

How do solar panels work?

Standard Solar panels for large-scale ( 1 MW and above) are generally constructed by 156 x 156 mm (6” x 6”) standard solar cells with 60 cells in one module and have three strings, each string being a series connection of 20 cells. All the three strings are brought in to the Junction Box and each string is bypassed by a diode.

How many solar cells are in a solar panel?

BACK GROUND A. Solar Panel Construction: Standard Solar panels for large-scale ( 1 MW and above) are generally constructed by 156 x 156 mm (6” x 6”) standard solar cells with 60 cells in one module and have three strings, each string being a series connection of 20 cells.

How many solar PV panels can a MPPT inverter have?

The number of solar PV panels in each string must be at least 4 modules. The PV array must not exceed one string. This step is not required for the inverter MPPT with only one string. The PV generator (PV array) consists of one string, which is connected to the three phase 5KW inverter.

Update Information

- Can the current levels of photovoltaic panels be mixed

- Photovoltaic panels on the roof of a large factory

- How much current can a set of photovoltaic panels generate

- How many watts of current does 54 photovoltaic panels have

- Huawei s current photovoltaic panels

- The main function of photovoltaic panels

- What is the current price of single crystal double glass photovoltaic panels

- The current of photovoltaic panels gradually decreases

- Solar panels to transform photovoltaic power stations

- Huawei Vilnius photovoltaic panels

- Huawei Tirana Solar Photovoltaic Panels

- How to choose monocrystalline photovoltaic panels

- Solar panels photovoltaic panels 30 square meters

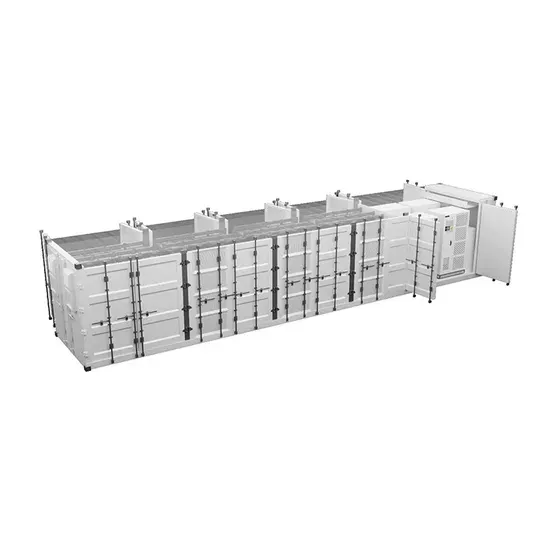

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.