lead-carbon battery energy storage technology solution

Performance study of large capacity industrial lead‑carbon battery for energy storage The upgraded lead-carbon battery has a cycle life of 7680 times, which is 93.5 % longer than the

Perspective and advanced development of lead–carbon battery

Dec 11, 2020 · With the global demands for green energy utilization in automobiles, various internal combustion engines have been starting to use energy storage devices.

profit analysis of large-capacity lead-carbon energy storage batteries

Evaluation and economic analysis of battery energy storage in smart grids with wind–photovoltaic | International Journal of Low-Carbon Table 1 shows the critical parameters of four battery

Large lead carbon energy storage

For large-scale grid and renewable energy storage systems, ultra-batteries and advanced lead-carbon batteries should be used. Ultra-batteries were installed at Lycon Station, Pennsylvania,

Lead carbon battery energy storage

Sep 27, 2024 · Lead carbon battery energy storage DOI: 10.1016/j.est.2022.105398 Corpus ID: 251432412; Performance study of large capacity industrial lead-carbon battery for energy

large capacity lead-carbon energy storage battery

The reason why it is called "advanced" is that lead-carbon batteries combine lead-acid batteries and supercapacitors into one. In terms of technology that takes advantage of the short-time

Design and implementation of Lead Carbon Battery

Apr 28, 2024 · Abstract: The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most successful commercialised

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Electrical energy storage with lead batteries is well established and is being successfully applied to utility energy storage. Improvements to lead battery technology have

Lead carbon battery energy storage

Sep 27, 2024 · Lead-acid batteries possess enormous promising development prospectives in large-scale energy storage applications owing to multiple advantages, such as low cost, high

Lead-Carbon Batteries toward Future Energy Storage:

Sep 19, 2022 · Despite the wide application of high-energy-density lithium-ion batteries (LIBs) in portable devices, electric vehicles, and emerging large-scale energy storage appli-cations,

Lead-doped biomass-derived carbon nanocomposite for enhanced lead

May 30, 2025 · Lead-doped rice husk-based activated carbon/carbon nanotube (CNTs/RHAC) composites were developed as high-performance additives for lead‑carbon batteries (LCBs).

Innovative lead-carbon battery utilizing electrode-electrolyte

May 10, 2024 · The study provides comprehensive insights into the synthesis, performance, and prospects of this novel lead‑carbon battery architecture, emphasizing its significance in the

Performance study of large capacity industrial

Feb 13, 2023 · The upgraded lead-carbon battery has a cycle life of 7680 times, which is 93.5 % longer than the unimproved lead-carbon battery under the same conditions. The large-capacity

Large capacity lead carbon energy storage

High capacity industrial lead-carbon batteries are designed and manufactured. The structure and production process of positive grid are optimized. Cycle life is related to positive plate

Prospects of large-capacity lead-carbon energy storage batteries

What is a high capacity industrial lead-carbon battery? High capacity industrial lead-carbon batteries are designed and manufactured. The structure and production process of positive

Long‐Life Lead‐Carbon Batteries for Stationary

Dec 20, 2023 · Lead carbon batteries (LCBs) offer exceptional performance at the high-rate partial state of charge (HRPSoC) and higher charge acceptance

What is Lead Carbon Energy Storage Battery?

Due to its outstanding advantages such as low cost and high safety, large-capacity lead-carbon energy storage batteries can be widely used in various new energy storage systems such as

Lead-Carbon Batteries toward Future Energy Storage: From

The lead acid battery has been a dominant device in large-scale energy storage systems since its invention in 1859. It has been the most successful commercialized aqueous electrochemical

Large capacity energy storage battery lead

(A and B) (A) LDS energy storage (B) battery energy storage. The maximum amount of available energy to meet demand with LDS (394 h, or 16 days of mean U.S. demand) and batteries (1.7

Effect of the Breakthrough of Lead Carbon Battery Technology on Energy

With the increasing demand of energy storage market, lead-carbon batteries with rapidly declining energy storage costs have a good prospect in the energy storage market. The lead-carbon

Lead-acid batteries and lead–carbon hybrid systems: A review

Sep 30, 2023 · For large-scale grid and renewable energy storage systems, ultra-batteries and advanced lead-carbon batteries should be used. Ultra-batteries were installed at Lycon

6 FAQs about [Large capacity energy storage lead-carbon battery]

Are large-capacity industrial lead-carbon batteries a viable energy storage option?

The large-capacity (200 Ah) industrial lead-carbon batteries manufactured in this paper is a dependable and cost-effective energy storage option. Renewable energy is quickly gaining traction throughout the world as a vital part of achieving a low-carbon future , , .

Can lead batteries be used for energy storage?

Lead batteries are very well established both for automotive and industrial applications and have been successfully applied for utility energy storage but there are a range of competing technologies including Li-ion, sodium-sulfur and flow batteries that are used for energy storage.

Are lead carbon batteries better than lab batteries?

Lead carbon batteries (LCBs) offer exceptional performance at the high-rate partial state of charge (HRPSoC) and higher charge acceptance than LAB, making them promising for hybrid electric vehicles and stationary energy storage applications.

Are lead-acid batteries a good energy storage option?

As a result, lead-acid batteries provide a dependable and cost-effective energy storage option , , , , , . Because of the high relative atomic mass of lead (207), which is one of the densest natural products, lead-acid batteries have low specific energy (Wh /kg).

What is the recycling efficiency of lead-carbon batteries?

The recycling efficiency of lead-carbon batteries is 98 %, and the recycling process complies with all environmental and other standards. Deep discharge capability is also required for the lead-carbon battery for energy storage, although the depth of discharge has a significant impact on the lead-carbon battery's positive plate failure.

Are lead batteries sustainable?

Improvements to lead battery technology have increased cycle life both in deep and shallow cycle applications. Li-ion and other battery types used for energy storage will be discussed to show that lead batteries are technically and economically effective. The sustainability of lead batteries is superior to other battery types.

Update Information

- Cameroon large capacity energy storage battery customization

- Large capacity energy storage battery in Cebu Philippines

- Singapore large capacity energy storage battery customization

- American large capacity energy storage battery manufacturer

- Lesotho large capacity energy storage battery quotation

- Lead-carbon battery energy storage cycle number

- Large energy storage battery company in Surabaya Indonesia

- Lead-carbon energy storage battery and lithium battery

- Xiaomi energy storage cabinet battery capacity

- Lead-carbon battery chemical energy storage

- Bulgaria energy storage battery field capacity

- Super large battery energy storage

- Large battery energy storage cabinet design

Solar Storage Container Market Growth

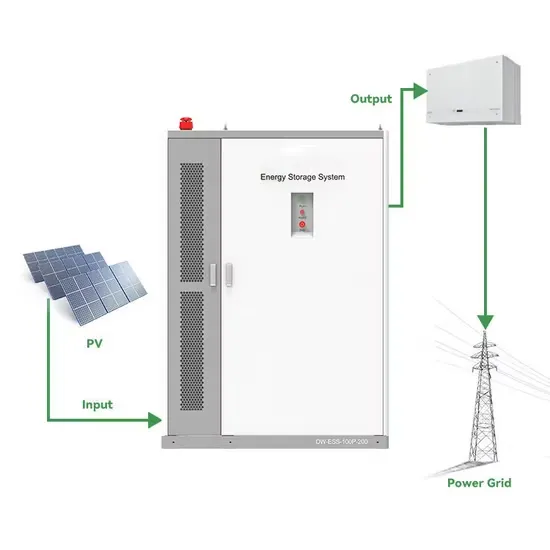

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

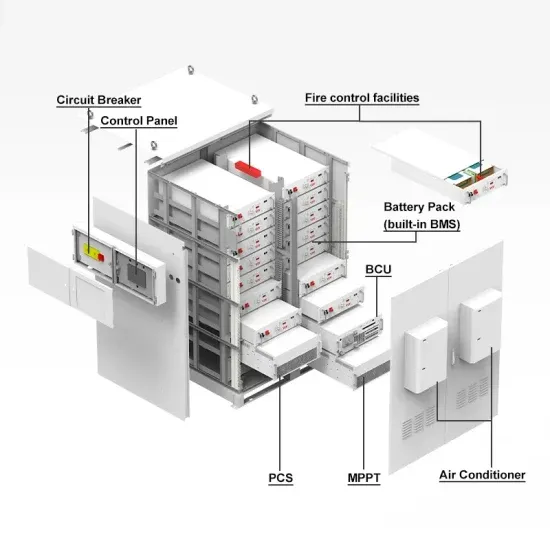

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.