Britain plans to install the first floating organic liquid flow

May 23, 2022 · The company said that the organic flow battery is very suitable for large-scale high-capacity energy storage applications, especially in places with high environmental

Wontai 300MW all-vanadium liquid flow energy storage

Jul 26, 2023 · The project will also build a new 100,000-kilowatt wind power, and 10MW/50MWh, 100MW/500MWh vanadium redox flow battery energy storage power station project and

What''s Behind China''s Massive New Flow Battery

Dec 10, 2024 · China has established itself as a global leader in energy storage technology by completing the world''s largest vanadium redox flow battery project.

Shanghai Electric''s 200Mw /1Gwh Liquid Flow Energy Storage

Oct 23, 2020 · The newly production of liquid-flow energy storage battery project factory adopts advanced automatic production line with a designed production capacity of 200MW/1GWH,

Vanadium electrolyte: the ''fuel'' for long-duration

May 22, 2023 · Image: CellCube. Samantha McGahan of Australian Vanadium writes about the liquid electrolyte which is the single most important material

The construction of Hami''s first 100MW/400MWh all-vanadium liquid flow

3 days ago · On July 21, a 100MW/400MWh vanadium liquid flow energy storage power station was completed in Hami Shichengzi Photovoltaic Industrial Park. The project was invested and

liquid flow battery energy storage project-All vanadium redox flow

Conpherson is an all vanadium flow battery manufacturer, which is committed to the research and development of intelligent energy storage vanadium battery technology and new energy

China''s Vanadium Flow Battery Storage Sector Updates (Jun

Jul 3, 2025 · Jimsar, Xinjiang: China''s largest all-vanadium flow energy storage project (100 MW/400 MWh) was completed, reducing annual CO₂ emissions by 1.6 million tons and

World''s largest vanadium flow battery project

Dec 9, 2024 · A firm in China has announced the successful completion of world''s largest vanadium flow battery project – a 175 megawatt (MW) / 700 megawatt

Up to 5 hours! A vanadium liquid flow energy storage project

May 30, 2025 · On May 28, in Jimusar County, Changji Prefecture, Xinjiang, the Jimusar 200,000 kW/1 million kW-hour all-vanadium liquid flow new energy storage project was connected to

The largest grid type hybrid energy storage project in China

Jun 19, 2025 · The largest grid type hybrid energy storage project in China: lithium battery and vanadium liquid flow energy storage with a 1:1 installed capacity ratio-Shenzhen ZH Energy

China to host 1.6 GW vanadium flow battery

Sep 24, 2024 · The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

The 10MW/40MW All-Vanadium Liquid Flow Battery Energy Storage Project

Apr 1, 2021 · The energy storage scale of all-vanadium liquid flow battery is 10MW/40MWh respectively. Dalian Rongke Energy Storage Technology Development Co., Ltd. is a high-tech

All-Vanadium Liquid Flow Energy Storage System: The

Sep 14, 2023 · Let''s cut to the chase – if you''re reading about the all-vanadium liquid flow energy storage system, you''re either an energy geek, a sustainability warrior, or someone who just

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium''s ability to exist in several states. By using one

China to host 1.6 GW vanadium flow battery

Sep 23, 2024 · The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

What are the vanadium liquid flow energy storage battery

The all-vanadium liquid flow energy storage battery project is a large-scale electrochemical energy storage demonstration project that uses vanadium redox flow battery (VRFB)

Weifang Built The First 1MW/4MWh Hydrochloric Acid-based All-Vanadium

Jul 4, 2022 · On July 1, the first phase of the first hydrochloric acid-based all-vanadium liquid flow energy storage power station in China was successfully completed in Weifang Binhai

The Wuhan project of advanced liquid flow batteries for

Jun 19, 2025 · The Wuhan project of advanced liquid flow batteries for neutralization and energy storage has been successfully connected to the grid for operation-Shenzhen ZH Energy

World''s largest vanadium redox flow project completed

Dec 9, 2024 · Rongke Power has announced the completion of the 175 MW/700 MWh Xinhua Ushi Energy Storage Project in the Xinjiang region, northwest China. The project will help

All vanadium liquid flow energy storage enters the GWh era!

Jun 19, 2025 · On the afternoon of October 30th, the world''s largest and most powerful all vanadium flow battery energy storage and peak shaving power station (100MW/400MWh) was

Vanadium Liquid Flow Energy Storage: The Future of Grid

Meet the vanadium liquid flow battery (VFB) – the Swiss Army knife of energy storage. As renewable energy adoption skyrockets (we''re talking 95% growth in solar/wind since 2020!),

The largest all-vanadium liquid flow energy storage

Relying on Panzhihua''s rich vanadium and titanium resources, the project will invest approximately 1.6 billion yuan to build Sichuan Province''s first vanadium liquid flow energy

6 FAQs about [Vanadium Liquid Flow Energy Storage Project]

What is vanadium flow storage technology?

Vanadium flow storage technology uses the flow of vanadium electrolyte across an ion exchange membrane. The advantages of this type of storage are safety, scalability and long-term operation. Vanadium electrolyte used in this battery is non-flammable and the battery operates at room temperature.

How much energy can a vanadium flow battery store?

A press release by the company states that the vanadium flow battery project has the ability to store and release 700MWh of energy. This system ensures extended energy storage capabilities for various applications. It is designed with scalability in mind, and is poised to support evolving energy demands with unmatched performance.

How long can a vanadium flow battery last?

Vanadium flow batteries provide continuous energy storage for up to 10+ hours, ideal for balancing renewable energy supply and demand. As per the company, they are highly recyclable and adaptable, and can support projects of all sizes, from utility-scale to commercial applications.

How does a vanadium flow battery work?

The key component of a vanadium flow battery is the stack, which consists of a series of cells that convert chemical energy into electrical energy. The cost of the stack is largely determined by its power density, which is the ratio of power output to stack volume. The higher the power density, the smaller and cheaper the stack.

Can vanadium be used as an energy storage unit?

Vanadium is an abundant silvery-gray metal, primarily mined in China, Russia, South Africa and Brazil, that is used as an energy storage unit. Part one of our three-part vanadium series focuses on the invention, applications, and uses of vanadium in this capacity.

Can vanadium chemistries solve large-scale energy storage problems?

Vanadium-based cell chemistries hold the promise to resolve persistent problems associated with large-scale energy storage. Commented Troy Grant, CEO, “Elcora is devoted to unlocking the full potential of solar and wind through large-scale energy storage capacity.

Update Information

- All-vanadium liquid flow energy storage battery project

- Leading enterprise of vanadium liquid flow energy storage battery

- All-vanadium liquid flow prefabricated energy storage container

- Liquid flow energy storage battery configuration

- Swaziland Liquid Flow Energy Storage Battery

- Long-lasting zinc-bromine non-attenuation liquid flow energy storage battery

- Aarhus Liquid Flow Energy Storage Power Station in Denmark

- Liquid Flow Battery Energy Storage Container

- Wellington Station Energy Storage System Project

- Energy Storage Project Business Plan

- Egypt Energy Storage Project

- Charging station energy storage project

- The world s largest energy storage project landed in the Netherlands

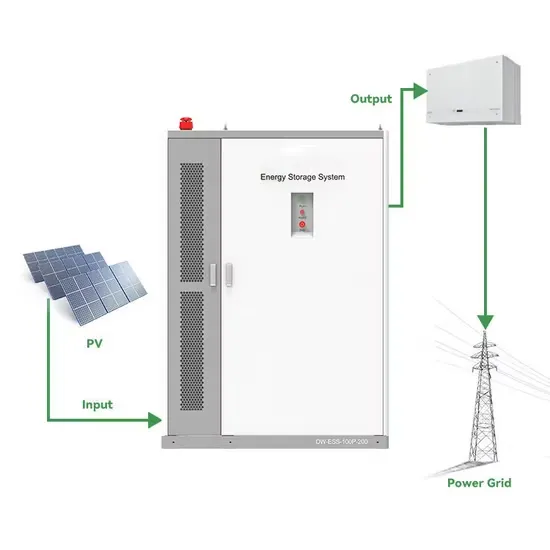

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.