Lithium Ion Battery Safety Guidance

Oct 16, 2019 · Battery Management System (BMS): Battery management systems are critical to the safe operation of lithium-ion battery packs. The system protects against: over-charge, over

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Who or What is ATIS? The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and

Lithium Battery Safety Procedure

Feb 29, 2024 · This Procedure describes the safety requirements for lithium (primary) and lithium-ion (secondary) batteries that are used in battery packs. This Procedure covers normal and

BATTERY HANDLING, MAINTENANCE & TEST

Apr 7, 2022 · Safety does not stop when a new or replacement battery system is commissioned; safety issues remain relevant through operation, periodic servicing, repair activities, and finally

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

What Are the Critical Aspects of Telecom Base Station Backup Batteries?

Mar 16, 2025 · Telecom base station backup batteries are essential for ensuring uninterrupted communication by providing reliable, long-lasting power during outages. Critical aspects

Communication Base Station Battery Cabinets | We

Behind every communication base station battery cabinet lies a complex engineering marvel supporting our hyper-connected world. As 5G deployments surge 78% YoY (GSMA 2023),

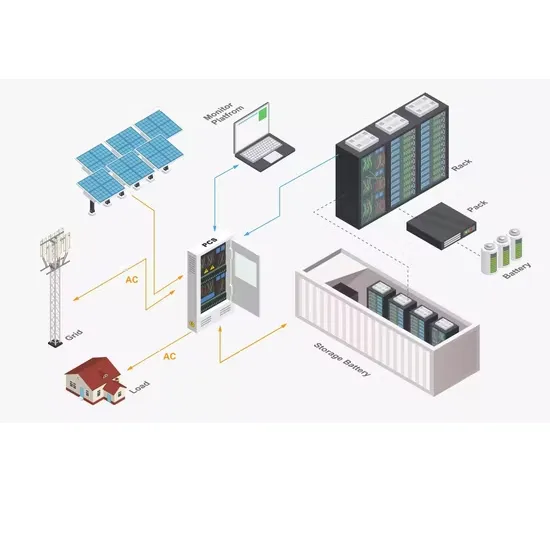

What equipment does the base station energy

Sep 21, 2024 · The equipment utilized in the base station energy storage cabinet comprises multiple essential components, which include: batteries, inverters,

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · 6.2.2 EQUIPMENT MOUNTING Do not attempt to unpack or move the battery cabinet without assistance. Use appropriate handling equipment rated to bear the weight and

Battery Cabinet Operation Manual | We Group E-Site

Have you ever considered how a single misinterpreted instruction in your battery cabinet operation manual could cascade into system-wide failures? With global energy storage

A Guide to Lithium-Ion Battery Safety

Jun 11, 2019 · Can cause short-circuiting and overtemperature Most likely during transportation and installation Shipment in partially charged state Roadside cabinets could be hit by a vehicle

Battery safety operation procedures for battery swap

ESS Energy Storage System for UL9540 Galaxy VS UPS for External Batteries with Galaxy Lithium-ion Battery Cabinets - Operation fast, efficient, and sustainable solution for urban

Battery Storage and Charging Standard Operating

Mar 14, 2024 · The overall purpose of this procedure is to ensure that risks associated with battery storage, charging and use are adequately managed in order to minimise the risk of

SOP For Battery Operation & Maintenance

Mar 27, 2025 · The document outlines the Standard Operating Procedure (SOP) for the operation and maintenance of batteries, emphasizing safety precautions and required personal

BATTERY ROOM REGULATIONS AND SAFETY BY: BOB

Jan 10, 2023 · IEEE-485 "Recommended Practice for Sizing Large Lead Storage Batteries for Generating Stations and Substations" This particular section defines loads and duty cycle, and

Maintenance BestPractices & Intervals for Substation

Oct 24, 2017 · Maintenance BestPractices & Intervals for Substation Equipment Presented by: Paul Schlies, President/CEO Energis High Voltage Services, Inc.

Safety, Storage, Operating and Maintenance Manual

Jun 3, 2020 · Safety, Storage, Operating and Maintenance Manual VRLA Battery Systems mSeries, DDm, DDS, DGX, DDV and SC Publication No. US-VR-OM-002 March 2008

6 FAQs about [Battery Cabinet Safety Operation Procedures Base Station]

What should I know before installing a battery cabinet system?

Never enclose batteries or battery cabinets in a sealed air tight room. All jewelry and watches must be removed prior to installing or servicing this system. Do not smoke or present flame near or around any battery cabinet system. Never leave a panel off or door open and unattended. 3. INSPECTION UPON RECEIPT OF GOODS

What is the purpose of a battery storage & charging procedure?

The overall purpose of this procedure is to ensure that risks associated with battery storage, charging and use are adequately managed in order to minimise the risk of injury or harm to workers. This procedure provides practical guidance on how to manage these health and safety risks. 3. SCOPE

How do quu work areas dispose of batteries?

QUU work areas that store, use or recharge batteries that are not considered to be general waste material must collect the material (battery components, cells and electrolyte liquids) in approved containers for disposal.

How do I install a battery cabinet?

Install plastic covers onto batteries. Some covers may need to be notched for locations with bus bars and/or cables in upward orientation. Ground the battery cabinet to the main building ground. A ground stud inside the cabinet is provided for this. Refer to the UPS or charger manual for start up and operation of system.

How do you ground a battery cabinet?

Ground the battery cabinet to the main building ground. A ground stud inside the cabinet is provided for this. Refer to the UPS or charger manual for start up and operation of system. 8. SYSTEM MAINTENANCE

What is the UBC code for battery storage?

or lead acid storage batteries. Basically, the UBC code is used as the foundation of the 1994 Uniform Fire Code Article 64.UBC 307 1.1 General. Group H Division 7 (term is defined below) occupancies shall include buildings or structures, or portions thereof, that involv the manufacturing, processing, generation o storage of materials that co

Update Information

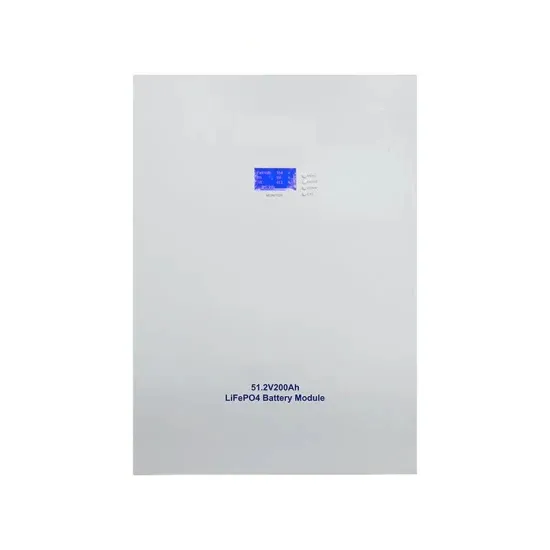

- Large square lithium battery station cabinet base station energy

- Battery cabinet current flow direction base station

- Battery cabinet and power box base station power generation

- High power battery cabinet base station energy

- Battery cabinet production line base station

- Making a battery cabinet base station at home is real

- Lithium battery station cabinet customized base station power generation

- Albania lithium battery energy storage cabinet price base station

- Tehran lithium battery station cabinet base station

- Battery cabinet base station power module power consumption

- DC screen battery cabinet base station

- Safety distance specification for battery energy storage system of communication base station

- The role of battery cabinet installation in base station power system

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.