A new IGBT control and drive circuit for high-power full-bridge

Jun 1, 2013 · High-power full-bridge inverter [1], [2] has been widely implemented in industry field, for example, laser power, high-frequency high-voltage switching power supply for electrostatic

Single Phase Half Bridge Inverter | Circuit, operation and

May 6, 2023 · Single Phase Full Bridge Inverter is basically a voltage source inverter. Unlike Single Phase Half Bridge Inverter, this inverter does not require three wire DC input supply.

Single Phase Full Bridge Inverter | Power4all

A single-phase full bridge inverter is designed to convert DC input into a two-level AC output with full supply voltage, making it ideal for applications ranging from home power backup to

Loss and efficiency comparisons of single-phase full-bridge inverters

Dec 27, 2023 · The purpose of this study is to analyze the performances of the single-phase full-bridge inverter according to different switch structures and to propose a cost-effective structure

Understanding IGBT Modules: Essential Components for

Nov 12, 2024 · Full-bridge modules are ideal for AC motor control and other AC applications. Chopper Modules Feature a single IGBT and a diode in a configuration used for DC-DC

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · This document describes the implementation of the inverter kit that used as a DC-AC part of the High Voltage Solar Inverter DC-AC Kit. The kit has a nominal input of 400-V

A Single-Phase Bridge Inverter For Grid-Connected

Oct 24, 2024 · r Insulated-Gate Bipolar Transistor (IGBT) are to be used as switching devices. The output voltage source from boo t converter was used in the system for the input voltage

BAP-1491F Full-Bridge IGBT Driver

An over current or short circuit fault output signal is annunciated for each phase leg on J1-pins 3, 6 and 9, see page 10 for additional information. Over Voltage Protection The over voltage

A new IGBT control and drive circuit for high-power full-bridge

Jun 1, 2013 · After rectifying and filtering the 3-phase voltage, we can get 510 V DC, which is sequentially processed by IGBT high-frequency inverter to get high-frequency AC. Afterwards,

Loss and efficiency comparisons of single-phase full

Feb 7, 2024 · For the performance comparisons, 3 kW inverters with direct current (DC) input voltages of 400 V and 700 V and an output voltage of 220 Vac/60 Hz are implemented and

AN-CM-270 Design and Implementation of a Single

Jan 7, 2025 · There are two main topologies of single-phase inverters; half-bridge and full-bridge topologies. This application note focusses on the full-bridge topology, since it provides double

H series 1200 V IGBTs on 3-phase full-bridge DC-DC

Power control solutions, based on the IGBT inverter technology, applied to welding machines, develop compact and reliable power sources to output a wide regulated high DC current at low

A Single-Phase Bridge Inverter For Grid-Connected

Oct 24, 2024 · Abstract —This paper proposed a grid-connected photovoltaic (PV) power conversion system based on a Single-Phase Bridge Inverter that converts DC to AC power.

6 FAQs about [Igbt full bridge inverter output voltage]

What is an IGBT based single phase full-bridge inverter?

Power circuit diagram of an IGBT based single phase full-bridge inverter. [] Grid-tie inverters are used to convert DC power into AC power for connection to an existing electrical grid and are key components in a microgrid system.

What are power control solutions based on IGBT inverter technology?

Power control solutions, based on the IGBT inverter technology, applied to welding machines, develop compact and reliable power sources to output a wide regulated high DC current at low DC voltage with high performance controls and low energy requirements providing a better arc stability and weld quality.

What is a full bridge inverter?

A single-phase full bridge inverter is a switching device that generates a square wave AC voltage in the output on the application of DC voltage in the input by adjusting the switch ON and OFF. The voltage in the output of a full bridge inverter is either -V DC,+V DC or 0. According to classification, inverters are five types.

How to solve a three-phase IGBT full bridge inverter circuit?

Based on the IGBT behavior model and utilizing the characteristics of FPGA multi channel time domain parallel computing, a steady-state and transient two-stage method is used to simulate, model and solve the three-phase IGBT full bridge inverter circuit.

What is the eficiency of the IGBT inverter?

The eficiency of the IGBT inverter was measured to be 92.9% under the same conditions, which confirms that adopting various switching structures increased the overall eficiency. When an input voltage of 400 V was applied in the switching frequency range of 40 kHz, the IGBT inverter had an eficiency of 94.2%.

What is the electromagnetic transient analysis program of IGBT full-bridge inverter?

The electromagnetic transient analysis program of the three-phase IGBT full-bridge inverter circuit can be divided into offline simulation and real-time simulation from the perspective of real-time performance.

Update Information

- Inverter rear bridge output voltage is too low

- Is the inverter output voltage 187V normal

- High voltage power supply full bridge inverter price

- Photovoltaic inverter and output voltage

- Inverter voltage output 190v

- String is the inverter output voltage

- The waveform of the voltage source inverter output

- Inverter can output voltage

- String inverter output voltage

- How many volts does the inverter output voltage

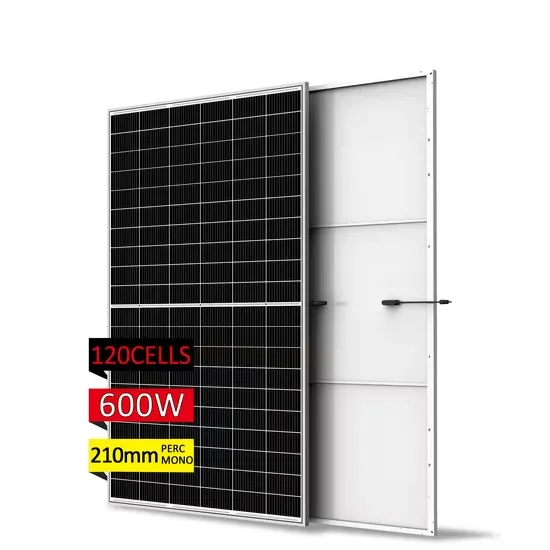

- 550w photovoltaic panel installed output voltage

- What is the output voltage of a 550w single crystal photovoltaic panel

- Inverter key point voltage

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.