Aluminium profiles for solar panels | BOAL Extrusion

Our aluminium profiles for solar panels combine smart design, durability, and flexibility, making them ideal for the high demands of solar panel installations. Pre-assembled systems: we

What are the Materials of Aluminum Photovoltaic Frames? A

Jun 13, 2025 · What Are Aluminum Photovoltaic Frames? Aluminum photovoltaic frames are structural components that encase solar panels to protect them from environmental damage.

The application of Aluminum profiles in Photovoltaic support

Aug 8, 2025 · Aluminum profiles play a vital role in modern photovoltaic (PV) systems. Thanks to their lightweight nature, high strength, corrosion resistance, ease of fabrication, and

Passive cooling of photovoltaic panel by aluminum heat

Jan 1, 2024 · One of the biggest problems of generating electricity by photovoltaic panels is that about 80% of the incoming solar energy is transformed into heat. The heat causes the rise of

Comparative assessment of solar photovoltaic panels based on metal

Aug 6, 2018 · Solar photovoltaic (PV) cells are used to resolve energy security and climate change problems. Although PV panels have long physical lifetimes, they would be eventually

Thermodynamic, environmental and economic analysis of solar

Mar 15, 2025 · Thermodynamic, environmental and economic analysis of solar photovoltaic panels using aluminium reflectors and latent heat storage units: An experimental investigation

Aluminium Alloys in Solar Power − Benefits and

Aug 16, 2013 · According to B€ odeker et al. (2010), 72% of the aluminum used in the PV industry devotes to the construction and mounting facilities, while

Solar Photovoltaic Systems: Integrated Solutions from

Jun 5, 2025 · Aluminum extrusion is the process of combining material properties and engineering advantages that make it exceptionally well-suited for renewable energy systems. There are

Top 10 Solar Panel Manufacturers in India 2025

Aug 13, 2025 · Discover the top 10 solar panel manufacturers in India 2025. Compare leading brands, technologies, and prices to choose the best solar solution for you.

Aluminium Frame for Solar Panel

6 days ago · Aluminium solar panel frames are essential components of photovoltaic systems, providing structural support while securing and protecting solar panels from mechanical

ALUMINIUM SOLAR PROFILES CATALOGUE

Jan 2, 2020 · Solar Aluminium Panels Solar Panels, generally comprising of arrays of Photovoltaic cells, use the solar energy directly from the Sun to generate electricity for our daily use. Being

Efficient aluminum solutions for long-lasting solar systems

From precision-engineered photovoltaic (PV) mounting structures and module frames to specialized solar system components, our integrated aluminum manufacturing capabilities

Aluminum Frame Design and Structure in Solar Panels

Aluminum Frame Design and Structure in Solar Panels When it comes to harnessing the power of the sun as a renewable energy source, solar panels play a crucial role. These panels,

A comprehensive review on the recycling technology of

Apr 5, 2024 · With the aim of realizing the goals of the Paris Agreement, annual solar power generation on a global scale using silicon PV panels had exceeded 1000 TWh by the end of

6 FAQs about [Solar Photovoltaic Panel Aluminum]

Can aluminum be used for photovoltaics?

In all these applications, however, the success of photovoltaics relies on using aluminum architectural components for both fixed and moving structures. Here, we discuss the benefits and drawbacks of aluminum for applications in the solar power industry as well as some design considerations for framing systems. What Are The Drawbacks?

Is aluminum a good material for solar panels?

With its advantages of light weight, high strength, corrosion resistance and durability, aluminum is widely used in building solar panel frames and photovoltaic supports. Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules.

Why are aluminum panels used for solar panels?

Extruded aluminum profiles are usually used for solar panel frames and solar mounting system, because aluminum extrusions have high strength, light weight and strong corrosion resistance. The aluminum frame seals and secures the solar cell module between the glass cover and back plate, ensuring structural stability and extending battery lifespan.

Which materials are used in solar PV?

Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules. Products conform to CEE AAMA, GB, BS, En; CE, DNV, ISO9001 certifications and can provide the TUV and other certifications. Welcome contact

What are the benefits of aluminum extrusion for solar panels?

Here are just some of the benefits of the use of aluminum extrusion for solar panel installations. First, aluminum profiles are virtually limitless in design complexity. This means that any likely engineering requirement can be met by tailoring the profile to suit the exact performance requirements.

What are the advantages and disadvantages of aluminum solar panels?

And with is good conductivity, aluminum has gradually replaced the position of silver, copper and stainless steel in the solar panels. Compared with traditional materials, aluminum cooling speed is fast, which has a significant advantage in solar PV, because the increase of PV cell temperature will reduce the power generation efficiency.

Update Information

- 6 watt solar photovoltaic panel

- Looking for solar photovoltaic panel 1X2

- Photovoltaic solar panel brand in Busan South Korea

- Tokyo Solar Photovoltaic Panel Manufacturer

- 48v photovoltaic solar panel small block

- Solar Photovoltaic Panel Installation Agent

- Portable solar photovoltaic folding panel

- Mali photovoltaic panel solar energy manufacturer

- Liechtenstein solar panel accessories photovoltaic power generation installation

- Asian Photovoltaic Panel Solar Energy Supplier

- Uganda Ben Solar Photovoltaic Panel Factory

- Canadian rooftop solar photovoltaic panel manufacturer

- Ankara Solar Photovoltaic Panel Purchase Cost

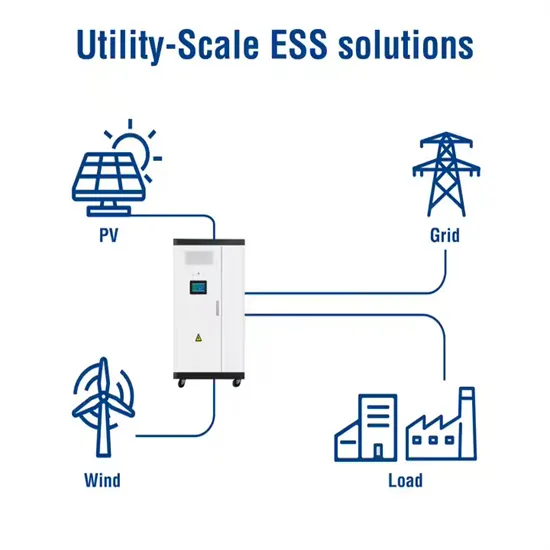

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.