A Beginner''s Power Supply Question

Dec 3, 2007 · Here''s my question, what do i use for say, the power supply running accessories such as lighted buildings The same thing you used 20 years ago. The Accessory out put of a

Electrification System for Rail Industry

Jan 21, 2015 · Caledonian railway cablesElectrification System for Rail Industry The electric railway needs a power supply that the trains can access at all times. Transmission of power is

Lighting to my outdoor railway

Jan 7, 2009 · I need some advise on adding lighting to my garden railway, specifically I have purchased some street lights and signals and I wite these to the track to provide power,

should electric trains have aux. power supplies??

Aug 18, 2003 · while watching the fun on the east coast last week i got to thinkingit would be a great idea to add auxillary diesel power supplies to electric passenger trains. i was thinking of

Traction Power Supplies Not another PSU

Oct 18, 2021 · The Subway in Glasgow, most of the Southern Region, Merseyrail, Docklands Light Railway and a few other routes use the third rail system to provide power to trains (London

Network Rail A Guide to Overhead Electrification

Jul 8, 2016 · This power supply must be something that trains can access at all times. The key objective of OLE designers is thus to ensure uninterrupted

Outdoor electrical cabinet

Nov 23, 2003 · I am planning to begin construction of my garden railroad and need to purchase an outdoor (i.e. weather proof) electrical cabinet to hold the transformer and other system

Railway Power Supply Solutions · Railway Power Supplies · Schaefer

Schaefer''s railway grade power conversion products include AC-DC power supplies, DC-DC power converters, rectifiers and battery chargers and DC-AC sine wave inverters. We

Types Of Train Fuel: Pros, Cons, And Efficiency

Discover the best for your needs. Explore the pros and cons of, electric power, and biofuels. Understand the factors that affect fuel efficiency and learn about the latest in renewable

Power supplies for railway infrastructure | Phoenix Contact

Our QUINT POWER power supplies under 100 W are suitable for these applications, since they do not require a protective conductor connection due to their high-quality insulation concept

Next-generation battery-driven light rail vehicles and trains

Jan 1, 2017 · Electric trains are more energy-efficient and generate fewer CO 2 emissions than other types of transportation systems. Next-generation light rail vehicles (LRVs) have been

(PDF) Traction Power Supply Systems in Electrical Railways Power

Jan 23, 2022 · The Cegelec Multi Train Simulator (MTS) is a suite of computer programs, which are used to assist the design of dc railway power supply systems. At Cegelec Projects Limited

Power supply for Railroad Signal

Jan 25, 2009 · I am restoring a 3-lamp signal for my grandson''s model train room. On teardown, it looks like the signal ran on low voltage DC? power. The bulbs inside are listed at 10V, 18 W. I

Enjoy Outdoor Model Trains: Tips for a Safe, Fun Setup

May 29, 2025 · Discover how to safely enjoy your model train set outdoors with tips on weatherproofing, layout design, power setup, seasonal themes, and maintenance.

Railway Traction Power Supply and Electrification Solutions

Power supplies for railway applications can be used either on-board or off-board. In particular, they have often used to power the following equipment: Railway trackside. Power supplies can

Electrification Methods | Consideration Of Your

Mar 3, 2025 · Electrification Methods for Your Network? Electrification is at the heart of modern rail operations, driving efficiency, reducing carbon emissions,

Railway Power Systems and Overhead Lines | Swartz

Aug 26, 2024 · Conclusion Railway power systems and overhead lines are integral to the operation of modern electric railways, providing the energy needed to power trains efficiently

Electric power accumulators in system of supplying

The main types of energy accumulators, which essentially can be used on railway transport in traction power system – traction sub-stations and traction network, electric motive power, are

Hydrogen fuel cell electric trains: Technologies, current

Mar 1, 2024 · Trains have been a crucial part of modern transport, and their high energy efficiency and low greenhouse gas emissions make them ideal candidates for the future transport

What Does A Train Run On? Types Of Propulsion And Fuel

Steam Engines Steam engines are the oldest type of train propulsion, but they are still used in some tourist trains and heritage railways. They use steam to power a piston engine, which in

6 FAQs about [Outdoor power supply that can be used on trains]

What are railway power supply solutions?

Railway Power Supply Solutions for on-board and trackside heavy rail applications. Custom & COTS. Rugged construction ensures long-life, reliable operation.

Why do railways need traction power supply products & solutions?

Contemporary railways require smart and energy-efficient traction power supply products and solutions to ensure safe, reliable, and environmentally sustainable operations. The document includes detailed information on the manufacturers and suppliers and their products, along with contact details, to inform your purchasing decision.

How can a railway power supply module be expanded?

Optionally, the modules can be expanded as follows: Robust enclosure that can withstand wind, sun, salt water, dirt or dust. For any system that depends on sophisticated electronics, everything begins with the power supply. Our shared objectives are to provide a safe and accessible railway power supply solution for on-board power systems.

Can TPSS power a railway?

As railways seek to become more sustainable, the integration of renewable energy sources with Traction Power Substations is gaining traction. TPSSs can be designed to incorporate solar panels, wind turbines, or other renewable energy sources, providing a greener power supply to the railway network.

What is included in a railway electrification & power supply document?

Railway electrification and power supply systems and equipment include, but are not limited to: The document includes detailed information on the manufacturers and suppliers and their products, along with contact details, to inform your purchasing decision.

What is a traction power substation (TPSS)?

A Traction Power Substation is a specialized facility that converts electrical power from the utility grid into a form that can be used to power electric trains. The TPSS performs several key functions: 1. Voltage Conversion: Transforming high-voltage electricity from the grid to a lower voltage suitable for the railway system. 2.

Update Information

- Can outdoor power supply be used on public transportation

- Can UPS be used as outdoor power supply

- How big an outdoor power supply is usually used

- Outdoor power supply that can be used with a hair dryer

- Large capacity solar light outdoor power supply

- New mobile outdoor power supply

- Algeria outdoor power supply sales

- Camping equipment outdoor communication power supply BESS

- Pyongyang outdoor communication power supply BESS price in the same city

- Banjul portable outdoor power supply manufacturer

- European outdoor power supply OEM manufacturer

- Outdoor power supply temperature resistance

- How much does one watt of outdoor power supply cost

Solar Storage Container Market Growth

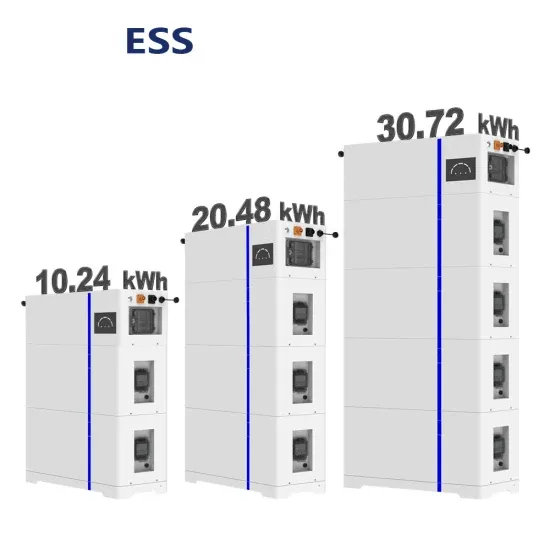

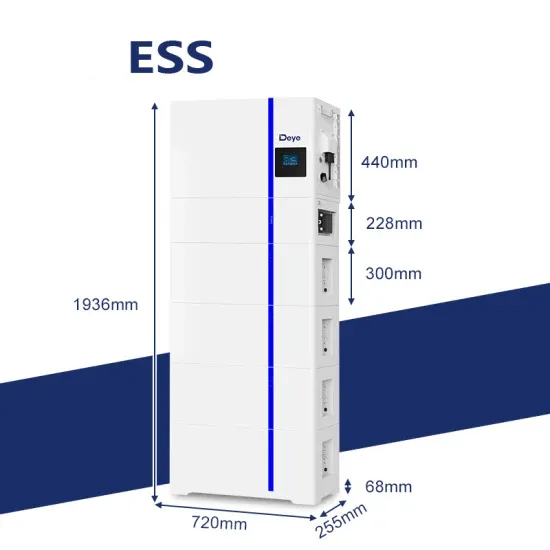

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.