GGD series AC low voltage distribution cabinet

Jul 23, 2025 · Product Summary The GGD low voltage switchgear is applied in power plant, substations dustry and mine corporations, etc., with rated voltage 400V, max operating

Low voltage distribution cabinet GGD solar energy storage

Our design scope includes wind power generation systems, high and low voltage switchgear, automation devices, frequency converter control cabinets, boiler operation consoles, power

Low voltage distribution cabinet GGD solar panel manufacturer solar

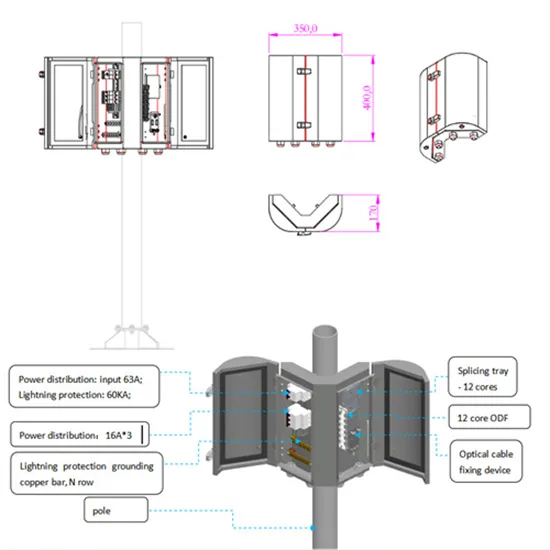

For low-voltage solar power stations that are connected to the grid, the PV grid connected cabinet can also incorporate additional devices for functions like measurement and protection.

Low voltage distribution cabinet GGD road solar street

Product Summary The GGD low voltage switchgear is applied in power plant, substations dustry and mine corporations, etc., with rated voltage 400V, max operating current 4000A and rated

GGD GGJ | Low voltage distribution cabinet | LV Apparatus

The GGD/GGJ series AC switchgear is designed for use in three-phase four-wire or three-phase five-wire power systems with a frequency of 50 Hz and a rated operating voltage of 400 V, for

Low voltage distribution cabinet GGD public solar cell

Explore cutting-edge energy storage solutions in grid-connected systems. Learn how advanced battery technologies and energy management systems are transforming renewable energy

Efficient Solar Energy Distribution Cabinet for Grid Connections

Jul 14, 2025 · GGD type AC low-voltage distribution cabinet is suitable for power plants, substations, factories and mining enterprises such as AC 50Hz, rated working voltage is 400V,

Transformation and Application of Traditional Low

Aug 13, 2025 · The main components of the traditional GGD low-voltage distribution cabinet are fixed products, the equipment runs in isolation, does not have the communication function, and

GGD Type AC Low-Voltage Distribution Cabinet

The GGD type AC low-voltage distribution cabinet is suitable for power distribution systems of power plants, substations, industrial and mining enterprises, and other electrical users with an

Low voltage distribution cabinet GGD outdoor solar power

GGD AC Low Voltage Power Distribution Cabinet The product is mainly applicable to the power grid with rated voltage of 400V and below and AC frequency of 50Hz. It is installed in the low

MNS® Low Voltage Distribution Board and Power Cabinet

Mar 17, 2024 · Features distribution board and power Cabinet conform to GB7251.3-2006. Product includes distribution board, lighting control panel, metering panel, and power cabinet.,

Substation Variable Frequency Control Cabinet High/ Medium/ Low Voltage

Jul 15, 2025 · Low voltage switchgear is a device used for power transmission, distribution, and energy conversion, suitable for industries such as power plants, petroleum, chemical,

Low voltage distribution cabinet GGD solar panel

GGD Low Voltage Distribution Cabinet is a new low-voltage power distribution cabinet designed according to the requirements of the Ministry of Energy, the majority of power users and the

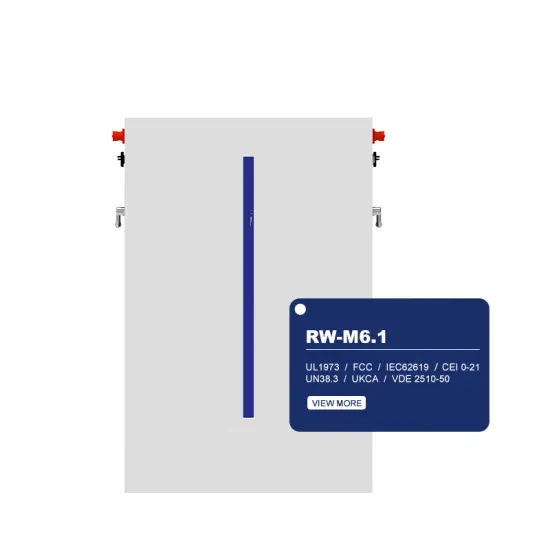

Complete Set of GGD Low Voltage Energy Storage Power Distribution

1.Durable and Customizable: The Complete Set of GGD Low Voltage Energy Storage Power Distribution Cabinets from ShengFa is specifically designed for Photovoltaic Grid-Connected

GGD Photovoltaic energy storage switchgear low voltage distribution cabinet

GGD - type AC low - voltage power distribution cabinets are applicable to power users such as power plants, substations, industrial and mining enterprises.

GGD series AC low voltage distribution cabinet

GGD type AC low voltage fixed switchgear is suitable for power plants, power stations, industrial and mining power enterprise users as AC 50HZ rated working voltage 400v power distribution

GGD Low-Voltage Grid Cabinet: 380V Power Distribution Unit

Aug 10, 2025 · The GGD Low-Voltage Grid Cabinet, designed as a 380V Power Distribution Unit, is a highly reliable and efficient solution for managing low-voltage power distribution in AC

Low voltage distribution cabinet GGD solar photovoltaic energy storage

The increasing penetration level of photovoltaic (PV) systems in low-voltage networks causes voltage regulation issues. This brief proposes a new voltage regulation strategy utilizing

6 FAQs about [Low voltage distribution cabinet GGD variable frequency solar energy storage cabinet price]

What is a GGD AC low-voltage distribution cabinet?

For low-voltage solar power stations that are connected to the grid, the PV grid connected cabinet can also incorporate additional devices for functions like measurement and protection. GGD AC low-voltage distribution cabinets are suitable for power plants, substations, and industrial enterprises.

What is GGD low voltage switchgear?

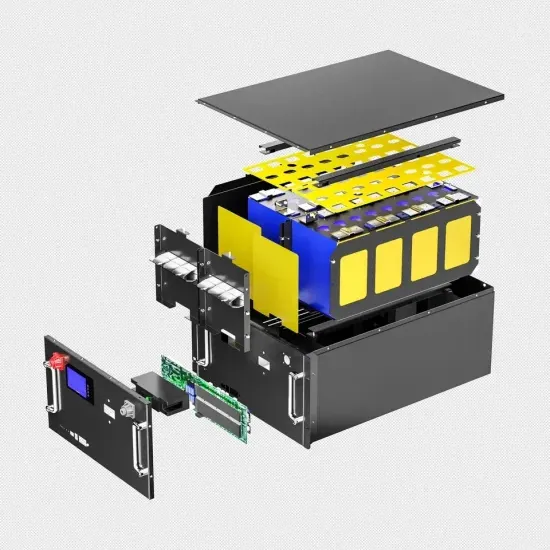

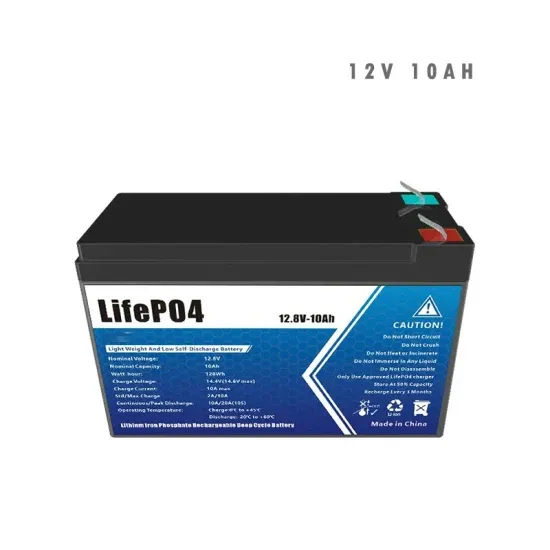

1.Product Overview GGD low-voltage switchgear is suitable for power distribution system of AC 50 Hz, rated working voltage 380 V and rated working current 3150 A in power plants, substations, and industrial enterprises, etc. It is used as lighting, electric energy conversion, distribution and controlling of distribution equipment.

What is a low-voltage distribution cabinet?

The device is a innovative type of low-voltage distribution cabinet that is in line with the safety, economic, reasonable and reliable principles. The product has high capability of breaking, high thermal stability, flexible electrical scheme, convenient combination, seriation, high practicability, innovative structure, high protection grade, etc.

What is a GGD cabinet?

3.Structure GGD adopts the general purpose cabinet body, its frame is made of 8MF cold forming sectional steel by means of partially welding and combination, the frame parts and special supporting parts are provided by the appointed manufacturer, so as to guarantee the cabinet accuracy and quality.

What is PV Grid connected cabinet?

IPKIS presents PV grid connected cabinet, a crucial part of solar systems that acts as the main connection point between a solar power station and the electrical grid.

How many schemes are there in GGD cabinet?

Main circuit of GGD cabinet has 129 schemes and 298 specifications (excluding the derived schemes and specifications due to function change of auxiliary circuit or change of control voltage). Wherein: GGD1 type has 49 schemes 123 specifications GGD2 type has 53 schemes 107 specifications GGD3 type has 27 schemes 68 specifications 3.Structure

Update Information

- Communication base station low voltage distribution cabinet GGD solar panel

- Solar communication base station China high and low voltage distribution cabinet price

- Communication high voltage energy storage cabinet solar energy

- Energy storage cabinet communication high voltage and price

- Price of energy storage cabinet converted to solar power supply

- Solar energy storage cabinet China price and price

- Containerized energy storage cabinet price base station

- Dili Modular Energy Storage Cabinet Price

- Communication base station solar cell energy storage cabinet production

- Photovoltaic energy storage cabinet solar energy engineering installation company

- Energy storage cabinet solar charging panel outdoor photovoltaic 220v

- Solar energy storage cabinet photovoltaic panels

- Energy storage cabinet mobile power supply is charged by solar energy

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.