Nader Electric Molded Case Circuit Breaker NDM2E-250 Series 3P Factory

Nader Electric Molded Case Circuit Breaker Ndm2e-250 Series 3p Preço De Fábrica Do Disjuntor Eletrônico De Plástico Shell - Buy Nader Mccb,250 Amp Mccb Ac 800v Para O Sistema

Blog / Company | Nader Circuit Breaker

Apr 6, 2024 · Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding,

良信电器Nader品牌介绍-良信断路器_低压电器_接触器_开关

Mar 3, 2025 · Maigoo网品牌库提供上海良信电器股份有限公司旗下良信电器Nader品牌相关信息,包括良信品牌介绍、成立时间、主营产品/服务

Nader circuit breaker factory in czech republic

Nader circuit breaker factory in czech republic supplier from China,we''re expert manufacturer with years of knowledge.For shoppers from around the globe,we support them with high high

How are circuit breakers made

Aug 6, 2021 · Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding,

Products / ATS | Nader Circuit Breaker

May 30, 2025 · Nader Automatic Transfer Switching Equipment (ATS):AC voltage includes 230V and 400V; Rated current from 16A to 125A; The number of poles includes 2p, 3P and 4P.ATS

How are circuit breakers made

Apr 2, 2021 · Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding,

Wholesale Nader Circuit Breaker Products at Factory Prices

Shop online for wholesale nader circuit breaker? Global Sources has a full-scale list of wholesale nader circuit breaker products at factory prices featured by verified wholesalers &

4 ways of wiring circuit breaker | Nader Circuit

May 30, 2025 · The wiring methods of the circuit breaker are front board, back board, plug-in type, and drawer type. Circuit breaker installation method: 1.

Blog | Quisure Circuit Breaker

Jun 13, 2025 · Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding,

China Mobile Carried Out On-site Audit on Nader | Nader Circuit Breaker

Apr 6, 2024 · On April 22th, 2010, the experts from Tianjin Subdivision, Anhui Subdivision, Heilongjiang Subdivision, Chongqing Subdivision of China Mobile Group visited Nader and

Wholesale Nader Circuit Breaker Products at Factory Prices

Find wholesale nader circuit breaker manufacturers from China, India, Korea, and so on. Source good quality nader circuit breaker products for sale at factory prices from online Chinese,

Products | Nader Circuit Breaker

May 30, 2025 · Nader focuses on the R&D and manufacturing of high-end low-voltage electrical products. These products made by Nader include Miniature Circuit Breaker, Molded Case

Blog | Nader Circuit Breaker

Aug 25, 2024 · Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding,

NDW3-2500 Air Circuit Breaker / Nader ACB / Nader Circuit

Brands like Nader, under the Liangxin umbrella, provide specialized products such as Nader MCCB (molded case circuit breakers), Nader MCB (miniature circuit breakers), and Nader

Circuit Breaker Manufacturer, MCB, MCCB Supplier

Nader Electrical was founded in 1999 by experienced industry experts. Due to its unique positioning to be quality and economical replacement of big brands like or Schneider, the

Contactor Relay-Shanghai Liangxin Electrical Co., Ltd. (Nader)

The partnership between Nader and Vanke Real Estate can be dated back to year 2009. Till now, its products have been used in over 1 million households in 65 cities throughout China. Over

Nader Entitled "Outstanding Enterprise of Waigaoqiao Fu

Apr 6, 2024 · Nader is entitled as Outstanding Enterprise of Waigaoqiao Functional Zone by Pudong New District Government and Waigaoqiao Free Trade Zone, April 15th, 2008. Famous

NDG3 Series Isolating Switch / Nader Disconnector / Nader

Brands like Nader, under the LAZZEN umbrella, provide specialized products such as Nader MCCB (molded case circuit breakers), Nader MCB (miniature circuit breakers), and Nader

Products / ACB | Nader Circuit Breaker

May 30, 2025 · Nader Air Circuit Breaker (ACB): voltage from 220V to 1000V; Current from 200A to 6300A; The number of poles is 3P and 4P. Some series have obtained CCC, CE, TUV and

Approaching Nader''s Future Factory | Quisure

Aug 6, 2021 · Facing the new demand of high-quality development of manufacturing industry, Nader''s "future factory" - Haiyan intelligent production

6 FAQs about [Nader circuit breaker factory in Portugal]

What products does Nader manufacture?

Nader focuses on the R&D and manufacturing of high-end low-voltage electrical products. These products made by Nader include Miniature Circuit Breaker, Molded Case Circuit Breaker, Air Circuit Breaker, Hydraulic Miniature Circuit Breaker and Automatic Transfer Switching Equipment, etc. 2021 Quick Selection Guide »

Who is Nader?

Nader, is one of the leading manufacturer of high-end low-voltage electrical apparatus industry, and the largest Miniaure Circuit Breaker of high-quality manufaturer in China, who listed at Shenzhen Stock Exchange.

Who is Nader electrical?

Nader Electrical was founded in 1999 by experienced industry experts. Due to its unique positioning to be quality and economical replacement of big brands like or Schneider, the company finds its dramatic development and market reputation.

Who is Nader's overseas market distributor & strategic partner?

As Nader's overseas market distributor and strategic partner, will bring China's leading low-voltage electrical products to the world. Quisure is Nader brand's authorized overseas market distribution and strategic partner, responsible for promoting, selling, commercial and after servicing Nader brand products.

What is the welding technology of products in Nader manufacturing line?

Today we are going to learn about the welding technology of products in Nader manufacturing line. Nader's spot welding workshop adopts fully automatic welding production line, which can fully produce key products and key components, reduce welding defects caused by human factors, and improve product consistency and production efficiency.

Who is Liangxin/Nader electrical?

Liangxin/Nader Electrical has been committed to become a leading low voltage electrical components manufacturer in China. When all the local competitors are trying their best to seek a cost leader position, Nader perseveres in high quality by well chosen raw materials and rigorous quality control process.

Update Information

- Nader circuit breaker factory in Azerbaijan

- Cheap nader circuit breaker factory manufacturer

- China nader circuit breaker factory exporter

- Nader circuit breaker factory in Argentina

- Micro circuit breaker factory in Abu-Dhabi

- House circuit breaker factory in Turkey

- Power circuit breaker factory in Vancouver

- Winch circuit breaker factory in Bhutan

- Winch circuit breaker factory in Bahamas

- Power circuit breaker factory in Chile

- Koten circuit breaker factory in Armenia

- Factory price circuit breaker in Ethiopia

- Royu circuit breaker factory in Brazil

Solar Storage Container Market Growth

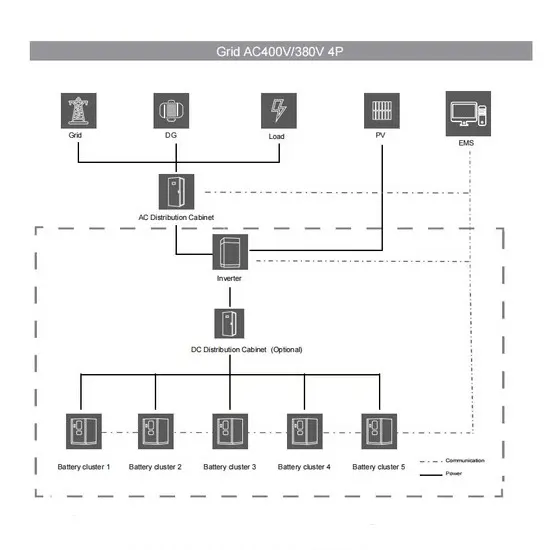

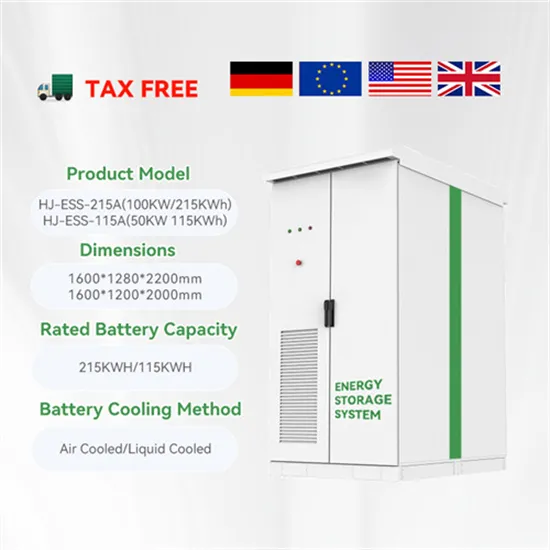

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

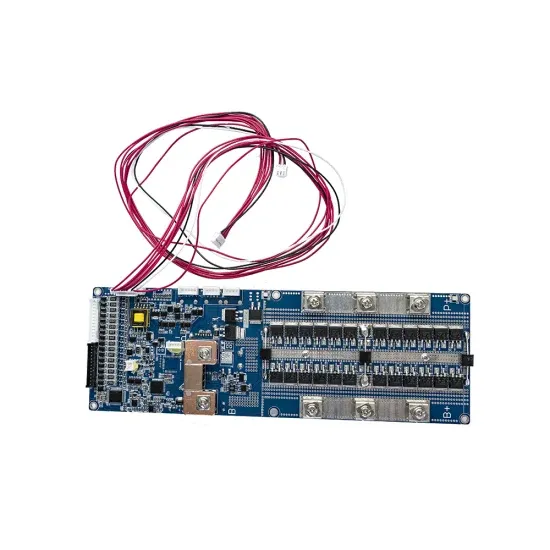

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.