Monitoring and control of internal temperature in power batteries

Feb 1, 2025 · The thermal characteristics and temperature sensitivity of batteries are introduced first, followed by a detailed discussion of various internal temperature monitoring technologies,

Multi-step ahead thermal warning network for energy storage

Jul 28, 2021 · In actual operation, the core temperature and the surface temperature of the lithium-ion battery energy storage system may have a large temperature difference.

Thermal effects of solid-state batteries at different temperature

Apr 1, 2024 · Solid-state batteries, which show the merits of high energy density, large-scale manufacturability and improved safety, are recognized as the leading candidates for the next

Advances and challenges in obtaining internal temperature

Reliable measurement or computation of the internal temperature of these batteries is essential for improving the efficiency of battery management systems (BMS), extending battery life, and

Analysis of the Thermal Conditions in a Lithium-Ion Battery

Feb 13, 2025 · Abstract The use of chemical current sources (CCS) in large stationary electrical energy storage systems (EES) is impossible without solving the problem of their thermal

Field study on the temperature uniformity of containerized batteries

Feb 1, 2025 · Numerous studies suggest that the operating temperature range for LIBESS should be limited to 25∼40 °C, with the maximum temperature difference between batteries not

What drives capacity degradation in utility-scale battery energy

Mar 1, 2022 · Battery energy storage systems (BESS) find increasing application in power grids to stabilise the grid frequency and time-shift renewable energy production. In this study, we

Estimating SOC and SOH of energy storage battery pack

Mar 15, 2024 · Estimating SOC and SOH of energy storage battery pack based on voltage inconsistency using reference-difference model and dual extended Kalman filter

Battery temperature difference range of energy storage

When the heating of the battery is large, the core temperature of the energy storage system will be significantly higher than the surface temperature, and the core temperature of the energy

A critical review on inconsistency mechanism

Jan 1, 2024 · Abstract With the rapid development of electric vehicles and smart grids, the demand for battery energy storage systems is growing rapidly. The large-scale battery system

A review of thermal management of batteries with a focus

Jul 1, 2025 · The performance, cycle life and safety of batteries are strongly influenced by temperature. However, fast charging and discharging can significantly increase heat

Different Types of Battery Energy Storage Systems (BESS)

Jan 14, 2025 · Conclusion Battery Energy Storage Systems (BESS) are crucial for improving energy efficiency, enhancing the integration of renewable energy, and contributing to a more

Influence of uncertainties in a battery pack with air cooling

Mar 30, 2025 · The present work predicts the influence of uncertainties in the geometry of the battery cells and the mass flow rate of cooling air over the maximum temperature difference of

Optimized thermal management of a battery energy-storage

Jan 1, 2023 · The performance of a battery system depends significantly on the operating temperature. In an extreme environment, the energy capacity and power density of a cell

What is the temperature difference requirement

May 12, 2024 · Temperature difference requirements for energy storage cells are critical for optimal performance and efficiency. 1. The operational temperature

Temperature effect and thermal impact in lithium-ion batteries

Dec 1, 2018 · Lithium-ion batteries, with high energy density (up to 705 Wh/L) and power density (up to 10,000 W/L), exhibit high capacity and great working performance. As rechargeable

Comparative study on the performance of different thermal

Apr 30, 2024 · A high-capacity energy storage lithium battery thermal management system (BTMS) was established in this study and experimentally validated. The effects of parameters

Field study on the temperature uniformity of containerized batteries

Feb 1, 2025 · The conventional liquid cooling system carries the risk of dew condensation and air cooling has poor thermal management performance for battery energy storage systems. To

Thermal effects of solid-state batteries at different temperature

Apr 1, 2024 · Most batteries, however, have relatively strict requirements of the operating temperature windows. For commercial LIBs with LEs, their acceptable operating temperature

Frontiers | Optimization of liquid cooled heat

Jul 1, 2024 · The optimization method ensured the maximum temperature control for the safe operation of the lithium-ion battery pack. The temperature of the

Analysis of the Thermal Conditions in a Lithium-Ion Battery

Feb 13, 2025 · Thermal resistance between Li-ion battery and the battery pack case was found to greatly reduce heat exchange with the environment. The temperature difference across the

What is the normal temperature difference of

Aug 22, 2024 · The normal temperature difference of energy storage batteries is critical for their efficiency and longevity. 1. Generally, the optimal operating

The influence of temperature on the operation of

Jul 7, 2018 · big difference whether a battery is just stored or also charged or discharged at high or low temperatures. Looking on storage, the state of charge (SOC) of th. battery is also

Effects of Temperature Differences Among Cells

Oct 4, 2017 · Given the same temperature difference, the cell energy differences within the parallel battery pack are 5–10 times higher than those within the

6 FAQs about [Energy storage battery temperature difference]

Does a lithium-ion battery energy storage system have a large temperature difference?

In actual operation, the core temperature and the surface temperature of the lithium-ion battery energy storage system may have a large temperature difference. However, only the surface temperature of the lithium-ion battery energy storage system can be easily measured.

Is temperature uniformity a problem in battery energy storage systems?

The temperature uniformity of batteries was analyzed under a wide range of supply liquid temperatures within a limited operation cycle. The conventional liquid cooling system carries the risk of dew condensation and air cooling has poor thermal management performance for battery energy storage systems.

What happens if the heating of a battery is large?

When the heating of the battery is large, the core temperature of the energy storage system will be significantly higher than the surface temperature, and the core temperature of the energy storage system will first reach the critical point.

What is the temperature difference between battery packs?

The temperature difference across the battery pack in a practically significant range of variables was from 2 to 16°С. At the same time, the characteristic temperature exceeded in a number of cases its regulated limit value, which created the risk of the battery’s thermal runaway.

Does high temperature affect lithium ion battery life?

Both low temperature and high temperature will reduce the life and safety of lithium-ion batteries. In actual operation, the core temperature and the surface temperature of the lithium-ion battery energy storage system may have a large temperature difference.

Can a lithium-ion battery energy storage system be measured?

However, only the surface temperature of the lithium-ion battery energy storage system can be easily measured. The estimation method of the core temperature, which can better reflect the operation condition of the lithium-ion battery energy storage system, has not been commercialized.

Update Information

- Kyrgyzstan energy storage low temperature lithium battery

- Cyprus energy storage low temperature lithium battery

- Dakka energy storage low temperature lithium battery

- Ghana Energy Storage Low Temperature Lithium Battery Factory

- Energy storage battery Gigawatt battery difference

- Difference between power supply battery and energy storage battery

- Paris Energy Storage Low Temperature Lithium Battery Factory

- Democratic Congo energy storage low temperature lithium battery factory

- How high a temperature can the energy storage battery withstand

- Sucre energy storage low temperature lithium battery

- Energy storage battery low temperature

- How much is the Duodoma energy storage battery

- Tuvalu energy storage lithium battery pack customization

Solar Storage Container Market Growth

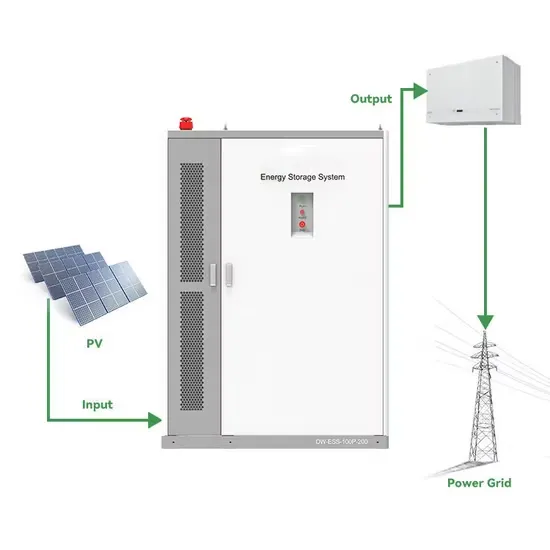

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.