A critical review of lithium-ion battery safety testing and

Aug 1, 2023 · The safety of lithium-ion batteries (LiBs) is a major challenge in the development of large-scale applications of batteries in electric vehicles and energy storage systems. With the

Understanding Global Lithium Battery Standards

Feb 11, 2025 · They have specific standards that ensure the safety of lithium-ion cells in consumer electronics (UL 1642), apply to battery pack durability (UL

Lithium-ion battery safety

Lithium-ion battery risks: safety issues for plant and workers With the widespread use of lithium-ion batteries and the resulting need to ramp up production, it is critical to understand the risks

Lithium Ion Battery Safety Guidance

Oct 16, 2019 · Never burn, overheat, disassemble, short-circuit, solder, puncture, crush or otherwise mutilate battery packs or cells. Do not put batteries in contact with conductive

General Lithium Ion Battery Safety General Safety

Apr 4, 2024 · Follow NJIT lab safety rules when working with lithium-ion bateries including appropriate work practices, control measures, personal protective equipment (PPE), waste

Safety risk assessment method for thermal abuse of lithium-ion battery

Feb 1, 2023 · The thermal safety of lithium-ion (Li-ion) batteries is of great importance for their further development and application. The accurate evaluation of

10 Essential Safety Rules For Lithium Battery Pack Design

May 8, 2025 · As lithium batteries power more and more applications—from energy storage systems and electric vehicles to consumer electronics—the safety of battery pack design has

Current trends, challenges, and prospects in material

May 1, 2023 · The advances in the outer material to enhance battery safety involve the improvement in battery thermal management systems (BTMS) materials and battery protective

(a) Scope and application

Oct 30, 2024 · Ensure that written standard operating procedures (SOPs) for Lithium and Lithium Ion powered devices are developed that include mechanisms to mitigate possible battery

Preventing Fire and/or Explosion Injury from Small and

Oct 1, 2020 · When designed, manufactured, and used properly, lithium batteries are a safe, high energy density power source for devices in the workplace. While lithium batteries are normally

Critical review and functional safety of a battery

May 21, 2022 · The battery management system (BMS) is the main safeguard of a battery system for electric propulsion and machine electrification. It is tasked to ensure reliable and safe

Lithium Battery Information Sheet

Nov 11, 2022 · SUPPLEMENTARY SAFETY AND HEALTH DATA: If the battery is broken or leaked the main hazard is the electrolyte. The electrolyte is mainly solution of Lithium chloride

A Detailed Guide on Safety and Security of

Mar 20, 2024 · An in-depth guide to ensure the safety and security of the battery pack. Find out the potential hazards that can be detrimental to the battery''s life

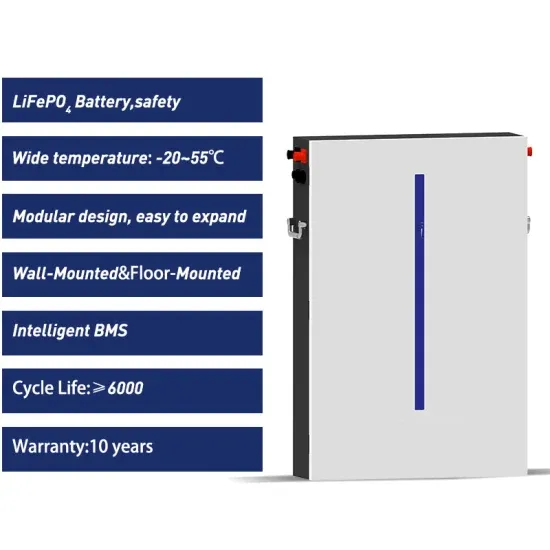

Why LiFePO4 Home Energy Storage Stands Out for Safety

1 day ago · For homeowners, this translates to peace of mind, knowing that their energy storage solution is designed with safety as a top priority. Comparing Safety Features: LiFePO4 vs.

Battery Pack Safety

Mar 27, 2025 · FAQs from NFPA Dealing with lithium-ion battery fires? Firefighters should use water on a lithium battery fire Unlike primary lithium batteries, lithium-ion batts have lithium salt

Lithium Ion Battery Risks: Understanding Hazards, Causes,

Lithium ion battery risks are real and can lead to fires, explosions, and toxic gas release. This in-depth guide explains causes, dangers like thermal runaway, and safe handling practices to

Battery Pack Design Considerations for Performance and Safety

1 day ago · At the conclusion of our webinar, Custom Battery Pack Design Considerations for Performance and Safety, we had several questions submitted to our presenter, Battery

Innovations in Traction Battery Pack Design for Enhanced Safety

Nov 26, 2024 · This article explores cutting-edge advancements in traction battery pack design aimed at enhancing safety while maintaining performance and longevity. The Importance of

6 FAQs about [Lithium battery pack safety]

Are lithium batteries safe?

Without proper controls, the potential life/health safety risks associated with lithium batteries are high in both impact and likelihood. As a result, these guidelines should be thoroughly reviewed and understood. Li-ion is a generic term, covering several types of battery chemistries and several formats for various applications.

What are the requirements for a lithium battery pack?

Shock and vibration requirements must be considered in the design of any battery pack. All cells must be protected from excessive shock and vibration. In general, regulations specific to the mode of transportation intended to be used (air, land, water) may limit the amount of lithium in any one container.

Do you carry unpackaged lithium-ion bateries?

us properties typically in teaching and research applications. This does not apply to bateries n personal devices such as smart phones, laptops, tablets, etc.Do not transport unpackaged/unsealed lithium-ion bateries in a metal box or metal container. carry unpackaged/unsealed lithium-ion bateries in y

What is a lithium ion battery emergency?

Shipping – refers to the requirements for sending either lithium ion batteries, or lithium ion batteries contained in equipment. Emergencies – refers to any event involving a lithium ion battery whereby there is a sudden release of energy, battery swell, explosion or fire, and steps to take to mitigate hazards.

How to store a lithium ion battery?

Experts recommend to put the cells in storage mode after every run, this will help the battery to lengthen the usable life span. Remove the lithium-ion battery from a device before storing it. It is a good practice to use a lithium-ion battery fireproof safety bag or other fireproof container when storing batteries.

How can outer materials improve battery safety?

The advances in outer material to enhance battery safety involve the improvement in battery thermal management systems (BTMS) materials and battery protective casing materials.

Update Information

- Lithium battery pack safety design

- Tashkent 72v75ah lithium battery pack

- Saint Lucia Power Lithium Battery Pack Customization

- Ukrainian 12v lithium battery pack

- Residual value of lithium battery pack

- 18V photovoltaic energy storage cabinet battery lithium battery pack

- 216v lithium battery pack

- 48v lithium battery pack has large self-discharge

- Basseterre lithium battery battery pack manufacturer

- Which brand of energy storage lithium battery pack is good

- North Korea pack lithium battery project

- Lithium battery pack for new energy vehicles

- Sucre 40a lithium battery pack

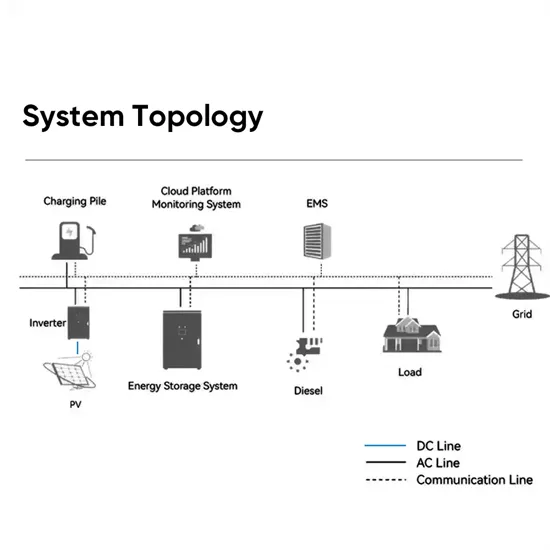

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.