A novel development of a new single switch inductor coupled DC-DC

May 10, 2024 · In the third objective, a two-leg inverter is proposed for the transformation of the DC voltage supply into three-phase powers. The MATLAB/Simulink tool is used to investigate

Wagan EL3720 1000W Slimline Plus AC to DC Power Inverter

May 23, 2017 · About this item 【WAGAN POWER INVERTER】 - 1000 watt continuous power and 2500 watts peak power. Taking a cue from its big brothers, the SlimLine 1000 Power

String inverters vs. power optimizers vs. microinverters: what

As you consider a solar panel system for your home, one of the key decisions you need to make is the type of inverter to install. Inverters convert direct current (DC) electricity generated by

SOLAR PLUS ENERGY STORAGE

Feb 11, 2019 · With increased interest of combining solar and energy storage, Dynapower has created a line of hybrid Solar Plus Storage inverters which have two DC inputs; one with

7. Trouble Shooting Table

Jan 6, 2025 · 7. Trouble Shooting Table Proceed as follows for quick detection of common faults. DC loads must be disconnected from the batteries and the AC loads must be disconnected

6 FAQs about [DC plus inverter power]

What are interactive inverters & converters?

Interactive inverters, converters, and ISE are intended to be operated in parallel with an electric power system (EPS) to supply power to common loads. These requirements cover battery systems as defined by this standard for use as energy storage for stationary applications such as for PV, wind turbine storage or for UPS, etc. applications.

Why is energy storage on a DC bus behind a PV inverter?

When storage is on the DC bus behind the PV inverter, the energy storage system can operate and maintain the DC bus voltage when the PV inverter is off-line for scheduled or unplanned outages or curtailments.

How efficient is a DC/DC inverter?

Diverting power from the inverter to the DC/DC comes at an efficiency cost. The battery roundtrip efficiency is approximately 93% plus twice the DC/DC conversion loss of 98.2% equals 98.2% x 93.0% x 98.2 %, and then times the 98.0% inverter efficiency to get the power out to the grid = 87.9%.

Will DC coupling drive down solar-plus-storage costs?

A DC-coupled battery system at Duke Energy’s Mount Holly test site using Dynapower equipment. Expectations are high that DC coupling will help drive down solar-plus-storage costs. Image: Dynapower. In AC-coupled solar-plus-storage installations there are two inverters, one for the PV array and another for the battery energy storage system.

What is DC-coupled and AC-coupled PV & energy storage?

This document examines DC-Coupled and AC-Coupled PV and energy storage solutions and provides best practices for their deployment. In a PV system with AC-Coupled storage, the PV array and the battery storage system each have their own inverter, with the two tied together on the AC side.

Can a PV inverter capture clipped DC output?

With storage attached to the array, the batteries can be charged with excess PV output when the PV inverter hits its peak rating and would otherwise begin clipping. This stored energy can then be fed into the grid at the appropriate time. Note that this ability to capture clipped DC output is only possible using a DC-coupled storage system.

Update Information

- Inverter changes DC power

- Inverter DC power supply

- How to match DC power supply with inverter

- Huawei EK inverter power

- Bidirectional inverter power storage cabinet

- Inverter exceeds power

- Inverter power efficiency

- Inverter production and power

- Best wholesale 1500 power inverter company

- West Africa Power Inverter Price

- Zimbabwe off-grid power frequency 20kw inverter

- Sri Lanka High Frequency Power Inverter

- DC Constant Voltage Uninterruptible Power Supply

Solar Storage Container Market Growth

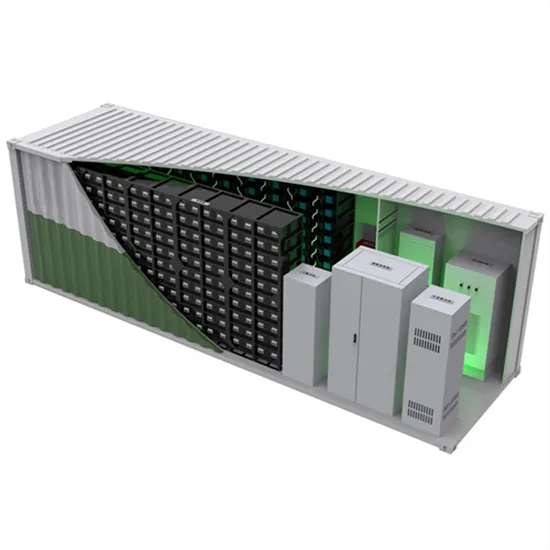

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.