The business model of 5G base station energy storage

The literature [2] addresses the capacity planning problem of 5G base station energy storage system, considers the energy sharing among base station microgrids, and determines the

Methods for Pricing Cabinet Work

Question I am curious how you price cabinet work. Obviously you need to take into account all of your expenses, but in the end, I''m sure experienced cabinetmakers aren''t calculating a quote

Estimating railway infrastructure project cost from

Sep 29, 2014 · The purpose of the paper is to estimate a railway project construction cost based on the nominal market price. Currently, estimation of project costs within railway infrastructure

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

What is Construction Cost Estimating & How To

Dec 17, 2024 · Construction cost estimating is a comprehensive calculation of direct and indirect costs, like labor and materials, to budget jobs and bid on

Optimized Power System Planning for Base Transceiver Station

Nov 6, 2019 · Telecommunication towers for cell phone services contain Base Transceiver Stations (BTS). As the BTS systems require an uninterrupted supply of power, owing to their

Power consumption modeling of different base station types

Mar 3, 2011 · In this paper we developed such power models for macro and micro base stations relying on data sheets of several GSM and UMTS base stations with focus on component

CONSTRUCTION COST ESTIMATE

Oct 9, 2023 · BASIS OF DESIGN > COST The following table provides the calculation basis for the Cost Estimate exported: Conduit Sizes and Lengths are determined automatically during

Generation Cost Calculation for 660 MW Thermal Power

Dec 30, 2014 · Abstract: The Central Electricity Regulatory Commission (CERC) has the power of deciding the tariff for electricity generated by various power stations. Tariff is calculated on the

Electric Power System Asset Optimization

5 days ago · Introduction This paper summarizes the costing methodology employed by NETL in its costing models and baseline reports. Further, it defines the specific levels of capital cost as

Electrical Load Estimation – Part Two ~ Electrical

Nov 28, 2012 · In the previous topic " Electrical Load Estimation – Part One ", I explain the definitions of the most important terms in electrical load estimation

COST ESTIMATING METHODOLOGIES FOR SUBSTATION

Nov 20, 2023 · Analyze engineering, material cost, and construction considerations for transmission lines and substations Compare and contrast contracting methods to include

photovoltaic booster station energy storage system

This paper studies the energy storage and generation characteristics of the photovoltaic power generation coupling compressed air energy storage system for the 5 kW base station, and

Estimating construction costs and schedules : experience with power

4 days ago · This paper helps national planning and finance ministries, power utilities, and financing agencies improve the estimate reliability for construction costs and schedules .

Electrical Load Estimation – Part Three ~

6 days ago · 4. Calculate the preliminary electrical load by multiplying the total gross area of the building by its load density. 5- Multiply the preliminary

Electric Power System Asset Optimization

5 days ago · As illustrated by Figure 1, this methodology defines capital cost at five levels: BEC, EPCC, TPC, TOC and TASC. BEC, EPCC, TPC and TOC are "overnight" costs and are

How to Estimate Construction Costs of a Nuclear Power Plant?

Aug 18, 2025 · As examples of NPP construction cost estimation process, this paper describes developing class 3 capital cost estimates of a nuclear-grade turbine building and of an

Fundamentals of Modern Electrical Substations

Mar 16, 2023 · Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in

Optimum sizing and configuration of electrical system for

Jul 1, 2025 · Proposed a model for optimal sizing & resources dispatch for telecom base stations. The objective is to achieve 100% power availability while minimizing the cost. Results were

Calculations:Electrical Load Schedule

Nov 16, 2021 · The electrical load schedule is an estimate of the instantaneous electrical loads operating in a facility, in terms of active, reactive and apparent power (measured in kW, kVAR

6 FAQs about [How to calculate the construction cost of base station power cabinet]

How do you calculate a generating station?

A generating station has the following data : Annual cost of fuel, oil etc. = Rs 9 × 10 ; capital cost = Rs 10 ; annual interest and depreciation = 10%. Calculate (i) the minimum reserve capacity of the station and (ii) the cost per kWh generated. Example 4.9.

How to calculate annual working cost of a power station?

The annual working cost of a power station is represented by the formula Rs (a + b kW + c kWh) where the various terms have their usual meaning. Determine the values of a, b (iv) annual cost of organisation and interest on cost of site etc. is Rs 5,00,000. Annual fixed cost.

What is the capital cost of a hydro power station?

Example 4.9. The capital cost of a hydro-power station of 50 MW capacity is Rs 1,000 per kW. The annual depreciation charges are 10% of the capital cost. A royalty of Re 1 per kW per year and

What are fixed costs in a power plant?

Fixed costs are the cost of equipment, land, financing, project management, grid connection, and construction of the power plant. These are usually expressed per unit of installed capacity (per kW or per MW). Fixed costs are regarded as “sunk costs”, because once the plant is erected and fixed costs are incurred they cannot be recuperated.

What is the cost of use of money in a power station?

The cost of use of money is known as interest. A power station is constructed by investing a huge capital. This money is generally borrowed this amount. Even if company has spent out of its reserve funds, the interest must be still allowed for, since this amount could have earned interest if deposited in a bank. Therefore, while calculating the

How do you calculate generating cost per kWh?

Estimate the generating cost per kWh delivered from a generating station from lubrication, maintenance etc. = 1·0 paise/kWh generated. Interest 5% per annum, depreciation 6% per annum of initial value. 50 MW. Example 4.8. A generating station has the following data :

Update Information

- How to calculate the cost of building a base station power supply

- How much does the power distribution room of a communication base station cost

- How much does it cost to change the power supply of Damascus 5g base station

- How much does the power supply cost for a communication base station

- After the base station is set up how to put the power supply

- How long will the wind power of the communication base station be disconnected if no one maintains it

- The function of the communication base station power cabinet is

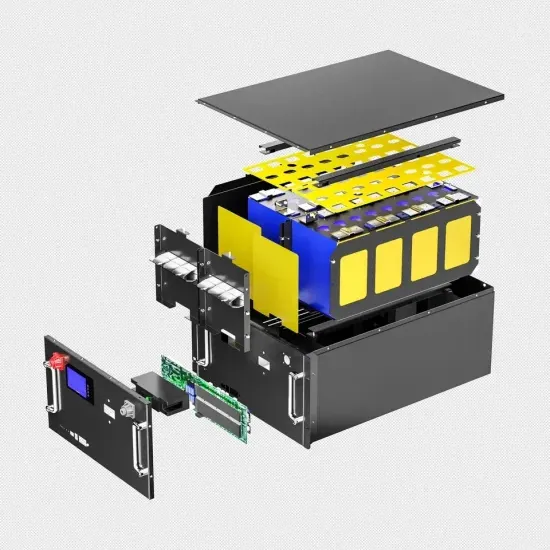

- Battery cabinet and distribution cabinet installation ESS power base station

- 5g base station power cabinet production standards

- How heavy is the 4G outdoor communication base station battery energy storage system cabinet

- How much power does the base station require

- Communication base station power cabinet design

- How much is the power supply of BESS outdoor base station in Uzbekistan

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.