What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · We will delve into the components that make up a lithium-ion battery system, exploring the differences of battery cells, battery modules, and

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · In this guide from A&S Power, we''ll explain the different types of Li-ion battery packs, help you compare cell sizes, and show how to choose the right one. The most widely used

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Lithium-ion Battery PACK Tech Explained

The lithium-ion battery PACK, also known as a battery module, is an integral part of the lithium-ion battery production process. It involves the connection of multiple lithium-ion monomer cell

How to Build a Lithium Ion Battery Pack? A Step

Apr 9, 2025 · Starting from selecting materials and tools needed in how to build a lithium ion battery pack, designing the battery pack, step by step in how to

A reliability design method for a lithium-ion battery pack

May 15, 2018 · Because of the complexity of the battery pack, a reliability design method for a lithium-ion battery pack considering the thermal disequilibrium is proposed in this paper based

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · What kind of tools and methods are involved in designing Li-ion batteries? This review paper analyzes the changes and developments in battery design methods investigating

BU-305: Building a Lithium-ion Pack

Oct 25, 2021 · Building a Li-ion battery pack begins by satisfying voltage and runtime requirements, and then taking loading, environmental, size and weight limitations into account.

Lithium-Ion Battery Pack Volume Calculation | True

Dec 29, 2024 · Popularity: ⭐⭐⭐ Battery Pack Volume Calculation This calculator provides the calculation of the volume of a lithium-ion battery pack, which is a key factor in determining its

How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Understanding Li-Ion Battery Packs: A Complete Guide

Aug 8, 2024 · Li-ion battery packs have revolutionized the way we power our devices. From the smartphone in your pocket to electric vehicles zipping down the highway, these batteries are

Simulation of lithium ion battery replacement in a battery pack

May 1, 2017 · The design and optimization of the battery pack in an electric vehicle (EV) is essential for continued integration of EVs into the global market. Reco

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

Battery Circuit Architecture

Aug 6, 2011 · Pack Thermistor Pack– Fig. 1. Block diagram of circuitry in a typical Li-ion battery pack. fuse is a last resort, as it will render the pack permanently disabled. The gas-gauge

Simple Ways to Pack Lithium Batteries: 12 Steps

Jul 26, 2025 · If you''re traveling by air with personal electronics that use lithium batteries or you need to ship some lithium batteries, it''s important to know the

6 FAQs about [A battery in a lithium battery pack]

What is a lithium-ion battery pack?

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and lightweight properties. In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack.

What are the components of a battery pack?

Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of cells assembled together in a specific configuration (series, parallel, or a combination) to achieve the desired voltage and capacity.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

How do you build a Li-ion battery pack?

Building a Li-ion battery pack begins by satisfying voltage and runtime requirements, and then taking loading, environmental, size and weight limitations into account. Portable designs for consumer products want a slim profile and the choice is a prismatic or pouch cell.

What is a battery pack & how does it work?

Essentially, it’s a set of lithium-ion cells working together to provide a stable power source. Each cell is like a tiny powerhouse, storing and releasing energy as needed. When combined, these cells form a battery pack that can power anything from a small gadget to a large electric vehicle.

What are the characteristics of a battery pack?

Voltage and capacity Voltage and capacity are fundamental characteristics of any battery pack. In Li-ion batteries, the voltage per cell usually ranges from 3.6V to 3.7V. By connecting cells in series, you can increase the overall voltage of the battery pack to meet specific needs.

Update Information

- Kyrgyzstan custom lithium battery pack

- Minimum voltage of lithium battery pack

- El Salvador lithium iron phosphate battery pack

- Iran cylindrical lithium battery pack

- Assembly 24V lithium iron phosphate battery pack

- Cylindrical lithium battery pack has good quality

- 12v lithium battery pack 20 amps

- Egypt lithium battery pack assembly equipment

- New Energy Lithium Battery Module Pack

- Customized lithium battery pack in Barcelona Spain

- 48V lithium battery pack in parallel

- 500ha lithium iron phosphate battery pack price

- Backup energy storage lithium iron phosphate battery pack

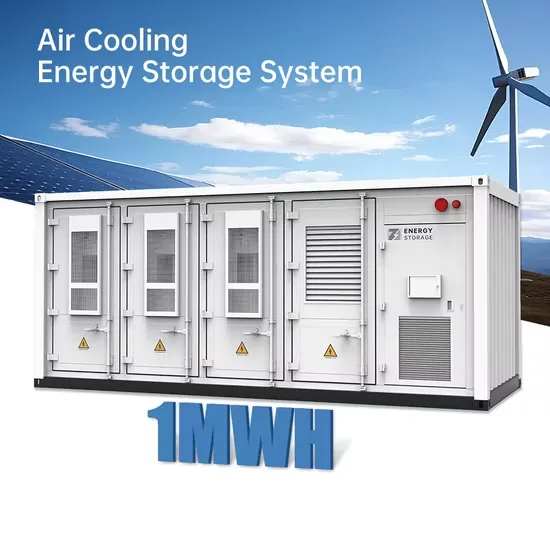

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.