Nantong Qiangsheng Photovoltaic Technology (QS Solar)

Company profile for solar panel, material and installer manufacturer Nantong Qiangsheng Photovoltaic Technology (QS Solar) Co., Ltd. – showing the company''s contact details and

DMEGC Solar Powers Module Production Entirely with 100

Presently, the grid-tied PV capacity at the DMEGC Solar manufacturing hub stands at 51.46 MW, delivering a self-consumption electricity tally of 22.28 GWh. Concurrently, there''s an agenda to

Photovoltaics in the Circular Economy | Photovoltaic

May 22, 2025 · Photovoltaics in the Circular Economy NREL applies its long-standing expertise in modeling and analysis to photovoltaics (PV) in the circular economy, supporting the

Greenhouse gas emissions embodied in the U.S. solar photovoltaic

Apr 26, 2025 · Here we analyze the silicon and solar PV supply chain for the United States (U.S.) market and find that the embodied GHG emissions of solar PV panel materials (such as

Comparing the carbon footprint of monocrystalline silicon

Jun 25, 2021 · This work discusses the life-cycle impact of manufacturing silicon monocrystalline (c-Si) (PV) panels in the United States compared to China. We compare the results using

LONGi Sets Global Benchmark with First Zero-Carbon PV

Aug 3, 2025 · Recognized by the World Economic Forum (WEF) as the PV sector''s first Lighthouse Factory, LONGi''s Jiaxing facility has long been a pioneer in automation, Industrial

德勤与远景联合发布《光伏组件——碳足迹及低碳发展报告

Aug 15, 2025 · 德勤 与 远景 联合发布 《光伏组件——碳足迹及低碳发展报告》 (以下简称"《报告》"),剖析了光伏产业在全球能源转型中的角色,以及中国作为光伏出口大国所面临的机

Greenhouse gas emissions embodied in the U.S. solar

Oct 16, 2024 · Solar photovoltaic (PV) electricity is considered to be an important source of electricity generation in the quest for net-zero carbon emissions. However, the growth of solar

How does solar panel recycling help reduce greenhouse gas

Dec 20, 2024 · By closing the loop through effective recycling, the solar industry enhances its environmental sustainability, ensuring solar energy remains a low-GHG option not just during

Deploying solar photovoltaic energy first in carbon

Dec 4, 2023 · Here we project the GHG emissions and mitigation of the global industrial chain of solar PV power through three manufacturing scenarios (continued concentration in China, M1;

Silicon-related materials demand and embodied greenhouse gas

Apr 1, 2025 · China is the world''s largest producer and consumer of solar photovoltaics (PV). A regional level study of the demand for silicon-related materials (Silica sand, MG-Si, SoG-Si,

Silicon-related materials demand and embodied greenhouse gas

Apr 1, 2025 · Here, we study and report the results of climate change implications of reshoring solar panel manufacturing as a robust and resilient strategy to reduce reliance on foreign PV

Assessing the carbon footprint of photovoltaic modules

Jun 1, 2023 · Bearing in mind that the environmental hotspots for PV modules mainly occur during the manufacturing phase, the aim of the paper is to develop a fully-fledged and adapted

Solar Panel Manufacturers and Products

Oct 13, 2024 · Solar Panel Manufacturers and Products The fastest-growing energy technology in the world is grid-connected solar PV. Solar power once again claimed the top spot for

Comparing the carbon footprint of monocrystalline silicon

Jun 20, 2021 · Eighty-five percent of the embodied GHG emissions are from PV panel production processes in China and other Asia–Pacific countries.

Greenhouse gas emissions embodied in the U.S. solar photovoltaic

Sep 21, 2023 · Here we analyze the silicon and solar PV supply chain for the United States (U.S.) market and find that the embodied GHG emissions of solar PV panel materials (such as

Dili Greenhouse Photovoltaic Panel Manufacturer

Discover how Dili''s specialized photovoltaic solutions are transforming greenhouse farming through clean energy integration. This article explores technical innovations, real-world

Reshoring silicon photovoltaics manufacturing contributes to

Mar 8, 2023 · Reshoring silicon photovoltaic manufacturing back to the U.S. improves domestic competitiveness, advances decarbonization goals, and contributes to mitigating climate change.

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Nevertheless, the manufacturing and end-of-life stages of solar power systems leave an environmental footprint and produce pollutants. Hence, a global perspective on

Update Information

- Photovoltaic panel greenhouse manufacturer in Democratic Republic of Congo

- Cairo Photovoltaic Panel Greenhouse Manufacturer

- Greek photovoltaic panel greenhouse cheap manufacturer

- Slovakia greenhouse photovoltaic panel manufacturer

- Nepal photovoltaic panel greenhouse manufacturer

- Shanghai energy storage photovoltaic panel manufacturer

- Beirut single crystal photovoltaic panel charging pile manufacturer

- Damascus Commercial Solar Photovoltaic Panel Manufacturer

- Greek explosion-proof photovoltaic panel manufacturer

- Manila Photovoltaic Panel Fixing Parts Manufacturer

- Uzbekistan Micro Photovoltaic Panel Manufacturer

- Kabul 2v photovoltaic panel manufacturer

- Romanian organic photovoltaic panel manufacturer

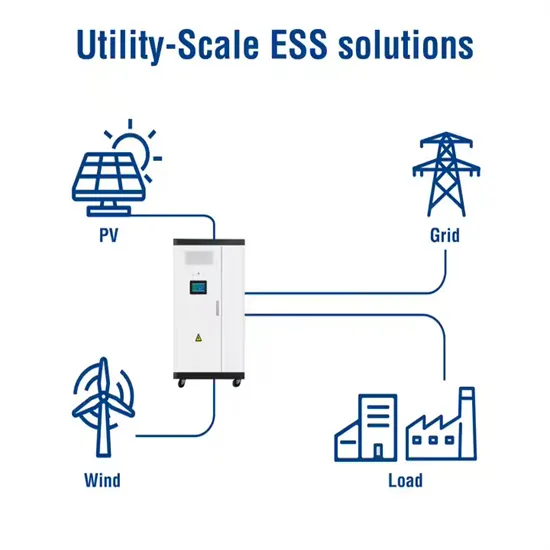

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.