Lightning protection solution for telecom communication base stations

May 8, 2025 · Lightning protection for telecom communication base stations involves a multi-layered approach, including direct and indirect lightning strike protection. This includes using

research on lightning protection and grounding safety

May 29, 2022 · Building 5g base station on power tower is an effective way to realize resource integration and save national resources. However, the voltage level and installe

UFC 3-575-01 Lightning and Static Electricity Protection

UFC 3-501-01, Electrical Engineering, provides the governing criteria for electrical systems, explains the delineation between the different electrical-related UFCs, and refers to UFC 3-575

(PDF) Analysis of Lightning Protection and Grounding Effect

Aug 26, 2020 · By analyzing the lightning protection and grounding requirements of the respective systems of the communication base station and the power tower, the impact of the towers on

Grounding and equipotential bonding

During operation and also in case of faults, electrical energy systems have an electromagnetic impact on the envi-ronment. To ensure faultless operation of equipment within and outside of

Lightning Protection Grounding Solutions for

6 days ago · 12 Lightning Protection & Grounding Solutions for Communication Sites Conductors from the tower legs to the radial system must have low inductance (large circumference) to

05. Bonding and Grounding

Mar 26, 2024 · The higher the impedance the lightning energy "sees", the greater the voltage increase. The higher the voltages, the more likely the energy will arc or take unwanted paths

THREE ESSENTIALS OF LIGHTNING PROTECTION:

Sep 10, 2018 · Abstract: Bonding, Grounding and Surge Protection are integral parts of a topologically shielded lightning protection system for reasons of codes compliance, good

ITU-T Rec. K.112 (07/2019) Lightning protection,

Recommendation ITU-T K.112 provides a set of practical procedures related to the lightning protection, earthing and bonding of radio base stations (RBSs). It considers two types of RBS:

Analysis of Lightning Protection and Grounding Effect of

Aug 1, 2020 · By analyzing the lightning protection and grounding requirements of the respective systems of the communication base station and the power tower, the impact of the towers on

Lightning protection scenarios of communication tower

Dec 1, 2011 · The outcome also shows that equipotential bonding of the grounding system, a distributed grounding network including a ring conductor and a suitable system of surge

IMS Guidelines: Minimum Standard for Grounding and

Jun 15, 2021 · IMS Guidelines: Minimum Standard for Grounding and Lightning Protection System at the IMS Stations. Based on statistics and experience in station''s installation and operations,

Lightning protection, earthing and bonding: Practical

May 1, 2021 · This Recommendation addresses the practical procedures concerning the lightning protection, earthing and bonding of radio base station (RBS) sites. The purpose of this

The Ultimate Guide to Lightning Protection and Grounding

Mar 7, 2025 · Conclusion Lightning protection and grounding are non-negotiable safety measures for C&I PV power plants. As the demand for solar energy grows, so does the need for robust

Technical requirements for lightning protection and grounding

Here we introduce the technical requirements for the installation project of lightning protection grounding for C network mobile base stations. 1 General technical requirements

Lightning Protection for Communications Facilities

Feb 14, 2011 · WHY GROUND? – one of the primary purposes of grounding electrical systems is to provide a low impedance path for transient overvoltages, such as lightning, to flow safely to

Telecommunications Grounding and Bonding | nVent

Aug 13, 2025 · Proper grounding and bonding for telecommunications infrastructure is essential to network reliability and public safety. nVent ERICO is a global leader in grounding and bonding

Lightning Protection Grounding Solutions for

6 days ago · 22 Lightning Protection & Grounding Solutions for Communication Sites On a well-designed ground system, the strike energy spreads out initially from the building.

6 FAQs about [Lightning protection and grounding requirements for communication base station energy management system]

How should a lightning protection System (RBS) be formed?

The earthing network of an RBS should be formed by a ring loop surrounding the tower, equipment room and fence, at a minimum. The mean radius re of this ring loop should be not less than l1, as indicated in Figure 1 and this value depends on the lightning protection system (LPS) class and on the soil resistivity.

Is a telecommunication tower impacted by lightning?

If the antenna is installed on the top of telecommunication tower, e.g., antenna positions 1 of Figure 29, it is considered to be impacted by or exposed to direct lightning strikes. Refer to [IEC 62305-3] for detail information about the protection angles and volume protected by an air termination system.

What is a lightning protection system (LPS)?

3.2.3 lightning protection system (LPS): Complete system used to reduce physical damage due to lightning flashes to a structure. NOTE – An LPS consists of both external and internal lightning protection system.

What is a radio base station (RBS) earthing network?

The most important objective of the radio base station (RBS) earthing network is to minimize the differences in potential between the conductive parts within the RBS site (equipotential bonding), which is beneficial for the safety, lightning protection and electromagnetic compatibility (EMC) performance of the equipment.

What is the minimum earthing resistance for RBS?

Therefore, whenever it is feasible, the RBS earthing resistance should be as low as 10 Ω. Alternatively, instead of achieving a low earthing resistance value, a minimum earthing network mean radius should be achieved. The earthing network of an RBS should be formed by a ring loop surrounding the tower, equipment room and fence, at a minimum.

How to protect the navigation light system in the equipment room?

Figure 12 shows protection of the navigation light system in the equipment room. If the NL has internal control circuits or it is based on LED technology, then an SPD is required on the top of the tower to protect the lamp. This SPD can be integrated into the lamp box.

Update Information

- Site requirements for communication base station energy management system

- Lightning protection and grounding construction of communication base station batteries

- Cairo Communication Base Station Battery Lightning Protection and Grounding Company

- Belgian communication base station wind and solar complementary lightning protection grounding

- Seoul communication base station energy management system room spot

- Reykjavik Communication Base Station Energy Management System Room

- Oslo communication base station energy storage battery requirements

- Marshall Islands Communication Base Station Energy Management System Location

- Austria Communication Base Station Energy Management System

- Communication Base Station Energy Management System Controller Company

- Wireless communication base station energy management system in Naypyidaw

- Armenia Communication Base Station Energy Management System Energy Storage Cabinet

- Design principles for communication base station energy management system

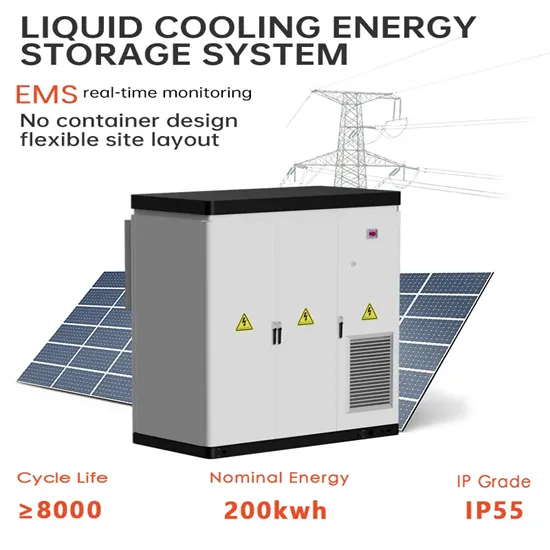

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.