Climate tech explained: grid-scale battery storage

Jul 17, 2024 · The fast-growing battery industry is most associated with electric vehicles, but its growth is also being driven by energy storage on a wider

How Much Does It Cost to Set Up a Battery Cell

On average, equipment costs can range from $30 million to $100 million, depending on the scale and technology used. A skilled workforce is essential for the successful operation of a battery

The Real Cost of Commercial Battery Energy Storage in 2025 | GSL Energy

Jun 9, 2025 · In today''s market, the installed cost of a commercial lithium battery energy storage system — including the battery pack, Battery Management System (BMS), Power Conversion

Tesla''s ''milestone'' Shanghai battery factory breaks ground

May 24, 2024 · SHANGHAI, May 23 -- U.S. carmaker Tesla broke ground on a mega factory in Shanghai on Thursday to manufacture its energy-storage batteries, Megapacks, a project

Tesla boosts China investment with plans for

Apr 9, 2023 · Tesla ''s Megapack system provides lithium-ion battery packs to help store renewable energy for electricity grids and represents a crucial driver for

Lithium-Ion Battery Production Is Surging, but at What Cost?

Sep 20, 2017 · The battery boom According to Bloomberg New Energy Finance, global battery-making capacity is set to double by 2021 to more than 278 gigawatt-hours per year.

Energy storage cost – analysis and key factors to

4 days ago · This article provides an analysis of energy storage cost and key factors to consider. It discusses the importance of energy storage costs in the

How Much Does Container Energy Storage Cost? A 2025

Nov 20, 2019 · Let''s cut to the chase: container energy storage systems (CESS) are like the Swiss Army knives of the power world—compact, versatile, and surprisingly powerful. With the

The Real Cost of Commercial Battery Energy Storage in 2025 | GSL Energy

Jun 9, 2025 · Discover the true cost of commercial battery energy storage systems (ESS) in 2025. GSL Energy breaks down average prices, key cost factors, and why now is the best time for

How much does factory energy storage cost? | NenPower

Apr 27, 2024 · The cost of factory energy storage varies greatly based on several factors, including the technology used, scale of storage, and specific application needs. 1. Battery

How much does factory energy storage power supply cost

Sep 30, 2024 · Apart from the battery technologies, the size and capacity of the energy storage solution also affects the overall expense. Larger systems that can store significant amounts of

How much does it cost to invest in an energy storage battery factory

Aug 12, 2024 · 1. The expenditure involved in establishing an energy storage battery factory is contingent on a multitude of factors, including but not limited to: 1. Technology selection, 2.

Cost Projections for Utility-Scale Battery Storage: 2021

Sep 17, 2021 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

What Are the 9 Startup Costs for Battery Manufacturing in

Jul 24, 2025 · How Much Does It Cost To Start Battery Manufacturing For Electric Vehicles? Starting an EV battery manufacturing business, such as VoltCraft Innovations, requires careful

Battery Energy Storage Lifecyle Cost Assessment Summary

Lithium ion battery energy storage system costs are rapidly decreasing as technology costs decline, the industry gains experience, and projects grow in scale. Cost estimates therefore

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · The Battery Cell Factory of the Future Offers Solutions The battery cell factory of the future addresses the challenges of cost optimization through

National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Lithium-based batteries power our daily lives from consumer electronics to national defense. They enable electrification of the transportation sector and provide stationary grid

How much does a factory energy storage system cost?

May 20, 2024 · The cost of a factory energy storage system typically involves several factors that can significantly affect the overall price. These include: 1. Type of technology used in the

6 FAQs about [How much does it cost to move an energy storage battery factory ]

Are battery electricity storage systems a good investment?

This study shows that battery electricity storage systems offer enormous deployment and cost-reduction potential. By 2030, total installed costs could fall between 50% and 60% (and battery cell costs by even more), driven by optimisation of manufacturing facilities, combined with better combinations and reduced use of materials.

How can a battery factory save money?

Upgrading to advanced, energy-efficient manufacturing equipment for batteries can yield savings of up to 20% on energy consumption, which is vital for maintaining a competitive battery factory investment. Reducing waste through recycling and sustainable practices is a proven method to lower production costs.

How much does energy storage cost?

For a 4-hour system, most costs were in the $2/kw-yr – $6/kW-yr range for large scale systems. A list of tasks can be found in the Energy Storage Operation and Maintenance Tracker . There may be some owner's tasks or responsibilities that should be accounted for separate from a service agreement.

How much does a gas storage system cost?

Generally speaking, the cost of the gas storage tank is the most expensive part of the entire system. Operation and maintenance costs include energy consumption and equipment maintenance. The current cost of compressed air energy storage systems is between US$500-1,000/kWh.

Do battery storage systems reach their end of life?

Although there has been a rapid increase in deployed energy storage, most systems have not reached their end of life and therefore the industry is still gaining experience decommissioning battery systems. In 2017, EPRI estimated end of life costs using the methodology and assumptions laid out in a battery storage disposal and recycling report .

How do you plan a battery factory investment?

Define realistic milestones by comparing your budget against $20 million to $50 million industry benchmarks for battery factory investment. Regularly update cash flow forecasts to reflect fluctuations in raw materials for lithium-ion batteries prices and labor costs.

Update Information

- How much does a household energy storage battery cost for 100 kWh of electricity

- How much does a battery energy storage cabinet cost in Beijing

- How much does an Avalu energy storage battery cost

- How much does a 300 kWh energy storage battery cost

- How much does a photovoltaic energy storage household battery cost

- How much does energy storage battery cost in Taipei

- How much does the battery of the Laayoune energy storage cabinet cost

- How much does Myanmar energy storage battery cost

- How much does it cost to replace the battery in the energy storage power station

- How much does the Brazilian energy storage battery cost

- How much does a household energy storage battery cost in Tallinn

- How much does the extra-long battery in the energy storage cabinet cost

- How much does a square meter of container energy storage cost in Minsk

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

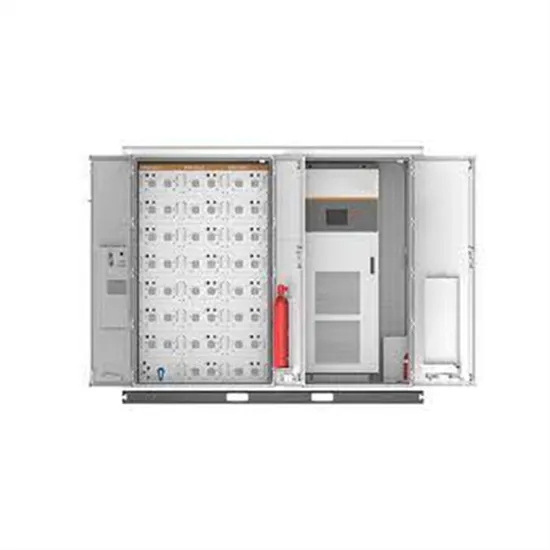

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.