63 AMP Portable Industrial Socket Box IP66 Stackable With

These Industrial Portable Socket Box are wildly used in oil, chemical industry, metallurgy, power plants, coal mines, machinery, textile, ports, docks and other industries, specifically for

What is a Power Distribution Box? A Comprehensive Guide

Users can connect them with generators to manage the power supply. Key Components of a Power Distribution Box Many components contribute to stable power management. Power

Heavy Duty Temporary Power Distribution Box IP67

Our Portable Distribution Board: Industrial Plugs, Industrial Sockets and Industrial Connectors adopt "preventing incorrectly insertion" design and have the advantages of good electric

Waterproof Industrial Socket Box with Temporary Power Supply Box

Waterproof Industrial Socket Box with Temporary Power Supply Box Outdoor Portable Repair Plastic Site Temporary Switch Box No reviews yet 6 sold Shanghai Gb Machinery & Electric

Syntax MD3 200A HDPE Power Distribution Units IP67 Industrial

High quality Syntax MD3 200A HDPE Power Distribution Units IP67 Industrial Socket Box 630x430x680mm from China, China''s leading PE portable distribution box product, with strict

IP67 Waterproof Customized Portable Industrial

Aug 7, 2025 · Socket distribution box is a new tvpe power distribution eauipment with overload.short-circuit and residual current protection devices, it adoots

Professional Portable Socket Boxes | Industrial Power

Celecca Professional Portable Socket Boxes - Industrial-grade power distribution solutions with IP44/IP67 protection. Featuring comprehensive range of mobile power boxes with CEE

IP65 Waterproof PE Portable Socket Box With Industrial

MK1 Industrial Portable Socket Box IP65 Waterproof PE Assembly With Industrial Plugs And Sockets MCB RCD Application Our Mobile thermoplastic distribution boxes are suitable for in-

Ultra-Load Industrial Power Station Rechargeable Portable

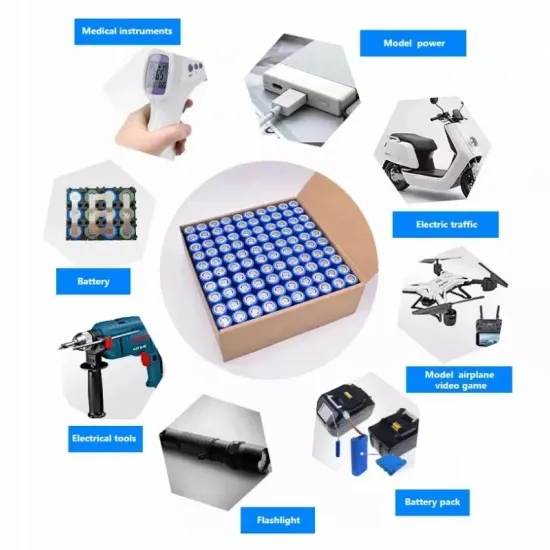

4 days ago · Our successfully developed energy storage industrial portable power station integrates DC welding power supply and AC power supply, the performance of which can

Update Information

- Structural design portable mobile power supply

- Uninterruptible power supply box manufacturers

- Morocco portable DC power supply manufacturer

- German portable energy storage power supply

- Portable automatic switching power supply

- Industrial and commercial energy storage is considered energy storage power supply

- The best portable outdoor power supply

- Generator Outdoor Small Portable Power Supply

- Eastern European portable energy storage power supply company

- How much does the BESS portable power supply cost in Managua

- Portable variable speed power supply

- Portable power supply manufacturer in Alexandria Egypt

- Malaysia s official portable energy storage power supply

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

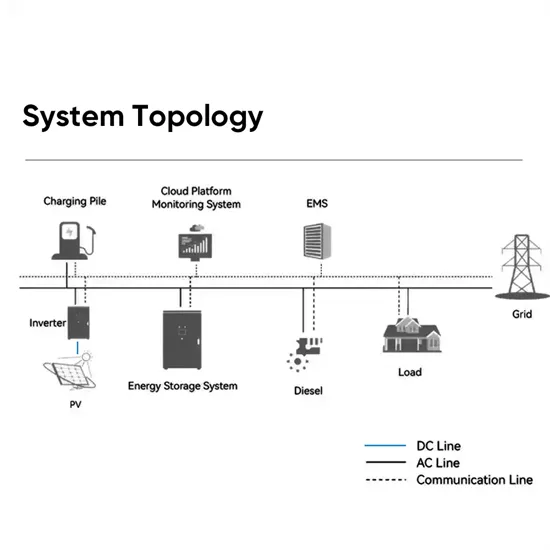

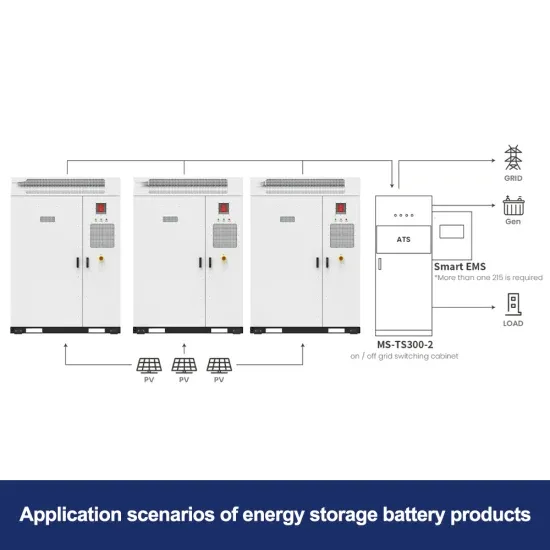

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.