Configuring Active Power Limitation

Apr 26, 2023 · Configuring Active Power Limitation In this article you will find out how to configure the limitation of the active power feed-in according to the parameters.

Unipolar and Bipolar PWM Inverter

Dec 29, 2014 · I. INTRODUCTION The basic inverter circuits performs the task of converting DC input power to AC output power. Inverter can be widely classified based on many parameters

Technical Note: Oversizing of SolarEdge Inverters

Oct 30, 2023 · The inverter limits or clips the power output when the actual produced DC power is higher than the inverter''s allowed maximum output. This results in a loss of energy.

Use the same device parameters as in Problem 5.6. The power

Use the same device parameters as in Problem 5.6. The power supply voltage is Vpp = 3.3 V. The channel length of both transistors is L = 0.8 μm. a. Determine the W/L ratio so that the

Inverter: voltage limits

Mar 12, 2023 · The inverter can perform the MPP tracking within a given voltage range, specified by VmppMin and VmppMax. the operating point is clipped at the limit voltage VmppMin or

PV inverter limits its own power

The quasi-Z-source inverter (qZSI) with battery operation can balance the stochastic fluctuations of photovoltaic (PV) power injected to the grid/load, but its existing topology has a power

Power Limit Control Strategy for Household Photovoltaic

Jul 16, 2021 · Under a power-limiting scenario, priority is given to power regulation through energy storage to absorb the limited active power. When the SOC of the BES reaches the upper limit

On the Grid-Tied Inverter Power Limitation

Nov 7, 2018 · The power limitation of grid-tied inverter is analyzed in this paper. For the grid-tied inverter to deliver the desired power into the grid, many factors should

Configuring Limitation of Active Power Feed-In

Oct 11, 2024 · The active power feed-in can be limited to fixed settings or controlled via external components. A Moxa device allows the grid operator, for example, to control the feed-in power

The optimal capacity ratio and power limit setting method of

Sep 1, 2023 · Aiming at the problem of optimal capacity ratio and power limit setting of photovoltaic power generation system, this paper takes the power cost of photovoltaic power

Geometry of the Feasible Output Regions of Grid-Interfacing

Apr 8, 2025 · Geometry of the Feasible Output Regions of Grid-InterfacingInverters with Current LimitsLauren Streitmatter, Trager Joswig-Jones and Baosen ZhangAbstract—Many resources

Array voltage sizing according to inverter

Aug 13, 2025 · The 2 first conditions are fuzzy conditions: if, during the simulation, the array voltage goes below the inverter limit VmppMin, or above the upper limit VmppMax, the inverter

Project design > Grid-connected system definition > Grid power limitation

Nov 7, 2024 · In the simulation The objective is to define an inverter maximum power (Pnom eff) which should correspond to the Grid specified limit power (PNom grid), plus the AC losses

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · If the PV input voltage is too low, power loss in the inverter''s boost circuit increases. If the PV input voltage is too high, it can cause power losses

Voltage THD smooth upper and lower bound comparison

Download scientific diagram | Voltage THD smooth upper and lower bound comparison for single-and three-phase inverters for six and ten levels. from publication: About Voltage Total

Growatt inverter limits

Jan 27, 2021 · Can someone confirm that they are able to power loads far in excess of the inverter limits when the unit uses the grid pass-through? Or, alternatively, can it be confirmed that

6 FAQs about [The inverter has upper and lower power limits]

How does an inverter lose power?

However there are limits in power, voltage and current. When attaining one of these limits, the inverter will clip the operating point on the intersection of the I/V curve and this limit. The power difference between the MPP of the arrays' I/V curve and the effective power of this operating point on the limit curves is accounted as inverter loss:

Can a low voltage inverter cause a power overload?

This is only possible when you define a low voltage for your array, i.e. few PV modules in series. Therefore in many cases when the operating (or nominal) current of the array is above the acceptable current for the inverter input, you will not see any Current loss during operation, but only Power overload.

What is the function of inverter input electronics?

The inverter input electronics assumes the function of choosing the operating point on the I/V curve of the PV array. In normal conditions it will choose the maximum power point (MPPT tracking). However there are limits in power, voltage and current.

How do you calculate inverter loss?

The power difference between the MPP of the arrays' I/V curve and the effective power of this operating point on the limit curves is accounted as inverter loss: The current limit condition may be specified: Imax = Pnom (DC) / VminPNom, where PnomDC = PnomAC / Efficiency.

How does an inverter track a power point?

In normal conditions it will choose the maximum power point (MPPT tracking). However there are limits in power, voltage and current. When attaining one of these limits, the inverter will clip the operating point on the intersection of the I/V curve and this limit.

What is the use of bus voltage in a photovoltaic inverter?

The increase in bus voltage is used as the control signal of the PV output current to reduce the photovoltaic output current, such that the PV output power is reduced from 3000 W to the inverter power limit value of 1500 W, which meets the requirements of the inverter output power limit.

Update Information

- Kigali Solar Power Inverter

- High quality wholesale 200w power inverter manufacturer

- What is the grid-connected power of the inverter

- Bosnia and Herzegovina Photovoltaic Power Inverter Manufacturer

- Are the glass of double-glass photovoltaic panels divided into upper and lower parts

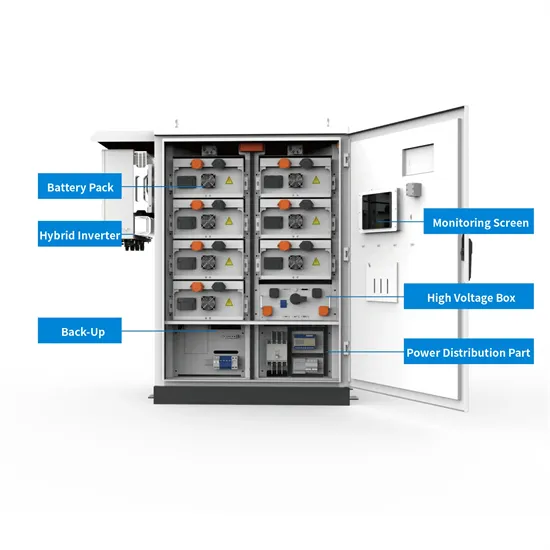

- Energy storage power station inverter structure

- RV low power inverter

- Photovoltaic inverter power rises slowly

- Off grid solar power inverter in Belarus

- Peru PV Power Station Inverter

- Single power inverter price

- Solar inverter high power 6000w all-in-one machine

- Inverter working power

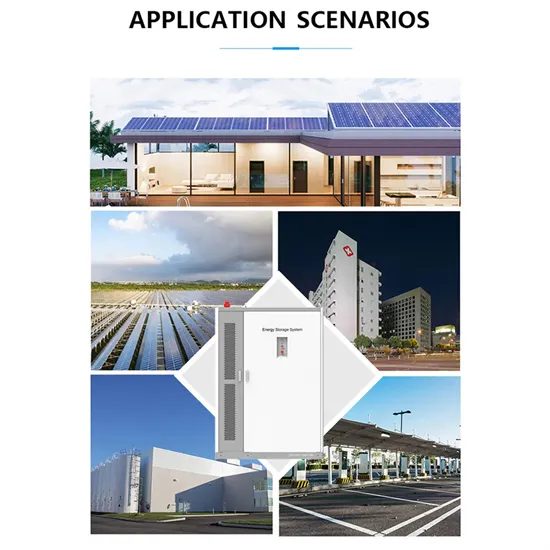

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

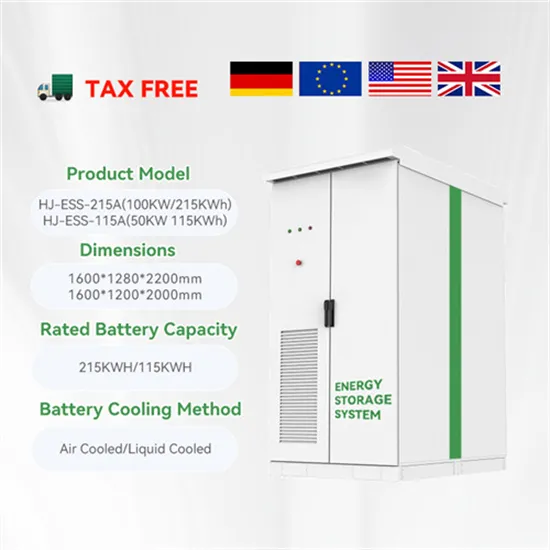

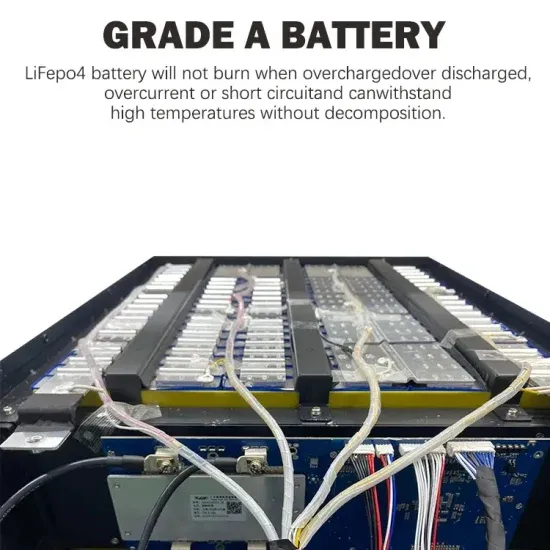

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.