Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · This smart coordination enhances reliability and extends battery life, especially in applications involving frequent cycling or high power demands. A

customized large scale liquid cooled energy

6 days ago · Containerized Liquid-cooling Energy Storage System represents the cutting edge in battery storage technology. Featuring liquid-cooling DC battery

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · In practice, an energy storage container contains multiple battery clusters, and the flow of these clusters is affected by the interaction between adjacent pipelines, so there is still

Detailed explanation of the structure of the liquid

The key system structure of energy storage technology comprises an energy storage converter (PCS), a battery pack, a battery management BESS-372K, the liquid cooling battery storage

Liquid Cooling Battery Cabinet Efficiency & Design

Unlike air cooling, which relies on circulating air to dissipate heat, liquid cooling uses a specialized coolant that flows through pipes or plates integrated within the battery cabinet. This fluid has a

Liquid cooled energy storage battery cabinet

Self-developed long-life energy storage battery, the system 10,000 cycles, Lcos reduced by 32% Ten thousand cycles of the system: battery cycle life of more than 12,000 times, system life of

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-integrated Liquid Cooled Energy Storage Cabinet doesn''t just run cooler—it runs smarter and lasts longer. In practical applications like

Outdoor 55KW/110KW/233KWh liquid-cooled energy storage cabinet

We outdoor 55kW/110kW 233kWh liquid-cooled energy storage cabinet adopts an integrated design. It combines high-performance lithium batteries, intelligent BMS, advanced EMS,

GSL-BESS80K208kWh / 261kWh / 418kWh Liquid-Cooled Battery Energy

Jul 3, 2025 · GSL-BESS80K 208kWh/261kWh/418kWh integrated liquid-cooled BESS with 80KVA output, 314Ah LiFePO₄ cells, and smart thermal control. Supports 10-unit parallel, perfect for

How big is the lead-acid liquid-cooled energy storage battery

Structure diagram of liquid-cooled energy storage lead-acid battery Liquid cooling systems typically use a liquid-cooled plate (LCP) in direct contact with the battery, which poses a risk of

Structure of air-cooled energy storage cabinet

Mar 3, 2024 · Conferences > 2022 4th International Confer With the energy density increase of energy storage systems (ESSs),air cooling,as a traditional cooling method,limps along due

Liquid cooling solution Outdoor Liquid Cooling Cabinet

Jun 24, 2022 · Introduction SUNWODA''s Outdoor Liquid Cooling Cabinet is built using innovative liquid cooling technology and is fully-integrated modular and compact energy storage system

Liquid Cooling Energy Storage Cabinet Introduction

The 186kW/372kWh liquid cooled energy storage cabinet adopts an integrated design concept, which is a highly integrated energy storage product that integrates battery system, BMS, PCS,

Two-phase immersion liquid cooling system for 4680 Li-ion battery

Sep 10, 2024 · 1. Introduction Lithium-ion batteries are widely adopted as an energy storage solution for both pure electric vehicles and hybrid electric vehicles due to their exceptional

Liquid-cooled energy storage battery charging station

Keywords: NSGA-II, vehicle mounted energy storage battery, liquid cooled heat dissipation structure, lithium ion batteries, optimal design. Citation: Sun G and Peng J (2024) Optimization

6 FAQs about [Energy storage liquid-cooled battery cabinet structure]

How are energy storage batteries integrated in a non-walk-in container?

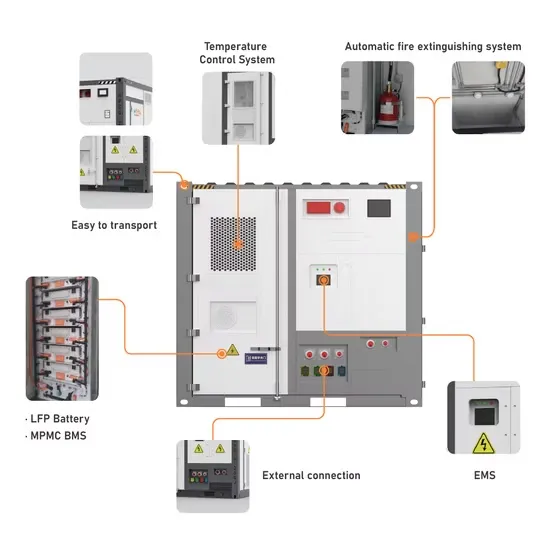

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What are the functions of the energy storage system?

The energy storage system supports functions such as grid peak shaving, frequency regulation, backup power, valley filling, demand response, emergency power support, and reactive power compensation. The 2.5MW/5.016MWh battery compartment utilizes a battery cluster with a rated voltage of 1331.2V DC and a design of 0.5C charge-discharge rate.

How does an energy storage inverter work?

Energy Storage Inverter: Each battery compartment connects to a 2500kW-PCS, enabling bidirectional energy conversion between the battery system and the grid. The battery compartment employs a 20’GP non-standard container measuring 6058mm×2550mm×2896mm, housing a total of 12 battery clusters, resulting in a total system capacity of 5.016MWh.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

How many battery clusters are in a 20 GP battery compartment?

The battery compartment employs a 20’GP non-standard container measuring 6058mm×2550mm×2896mm, housing a total of 12 battery clusters, resulting in a total system capacity of 5.016MWh. Each set of 12 battery clusters connects to a bus cabinet, forming a standard 5MWh DC compartment energy storage system.

Update Information

- Charging of liquid-cooled energy storage battery cabinet

- How much current does the liquid-cooled energy storage battery cabinet have

- Liquid-cooled energy storage battery cabinet manufacturers in Azerbaijan

- Ouagadougou liquid-cooled energy storage cabinet system lithium battery pack

- Liusha liquid-cooled energy storage battery cabinet

- Does Ecuador have liquid-cooled energy storage battery cabinets

- Outdoor safe charging energy storage battery cabinet ESS power base station

- Price structure of energy storage battery cabin

- How much does a battery energy storage cabinet cost in Palau

- Lithium battery energy storage cabinet recommendation

- Charging time of energy storage lithium battery cabinet

- Energy storage battery fit structure

- Immersed Liquid-Cooled Battery Energy Storage

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.