Double Pulse Test of the Paralleled Power MOSFETs in High Current 48V

Sep 28, 2022 · Double Pulse Test of the Paralleled Power MOSFETs in High Current 48V Inverter Design Abstract: Paralleling the discrete power MOSFETs is essential in low voltage (LV) high

AN-Power stage of 48V BSG inverter

Sep 9, 2021 · The power stage was developed to support customers during their first steps in designing 48V inverter for Belt-driven Starter Generator (BSG) application. The document

48V Systems: Driving Power MOSFETs Efficiently and

Aug 7, 2023 · In Peter Fundaro''s previous post on 48V automotive systems, he introduced a power-inverter system architecture and configuration as well as the design considerations for

TIDA-010936 reference design | TI

TIDA-010936 48V/16A small form factor three-phase GaN inverter reference design for integrated motor drives Design files Overview Design files & products Technical documentation Support

Power stage of 48V BSG inverter Application Notes | Infineon

Aug 2, 2018 · The power stage was developed to support customers during their first steps in designing 48V inverter for Beltdriven Starter Generator (BSG) application. The document

48-V, 10-A, High-Frequency PWM, 3-Phase GaN Inverter Reference Design

Apr 3, 2017 · Description Low-voltage, high-speed drives and low-inductance brushless motors require higher inverter switching frequencies in the range of 40 kHz to 100 kHz to minimize

48V systems: Design considerations for a typical auxiliary

Aug 3, 2023 · In this blog, I''ll discuss the main considerations in powering a brushless DC motor (BLDC) off of a 48V battery supply. BLDCs are highly efficient motors and a good fit for battery

The Growatt 3kVA 48V Inverter

3 days ago · The Growatt 3kVA 48V Inverter is designed to deliver dependable energy for households and small businesses. Because it uses advanced inverter technology, the Growatt

Top 48V Inverters for RVs, Campers, and Off-Grid Setups

Jul 8, 2025 · This article analyses the finest 48V inverters for RVs, campers, and off-grid setups in 2025, focussing on their features, possible technological capabilities, and practical uses. What

Design your own Sine Wave Inverter Circuit from

Dec 19, 2024 · In this article I have explained comprehensively regarding how to design a sine wave inverter without any form of coding or complex circuit

Reference design supports 48 V, 72 V, and 96 V light EV

May 6, 2025 · Arrow Electronics, in collaboration with Vishay eMobility, today announced the launch of a low-voltage traction inverter reference design tailored for light electric vehicles

48V, 85A Small Form-Factor Three-Phase Inverter

May 31, 2025 · This reference design demonstrates a 48V DC input, 85ARMS output, three-phase motor drive inverter. The 100V intelligent half-bridge gate driver DRV8162L enables a small

Simple 48V Inverter Circuit

Nov 25, 2022 · This project presents a design and construction of a three-phase inverter, drive circuit and dc-link capacitor bank. The inverter should be able to supply an electrical machine

TIDM-02017 reference design | TI

TIDM-02017 is a 5kW 48V traction-inverter reference design which aims to provide a foundation for you to develop high-performance high-efficiency traction-inverter systems for 2-wheeler

TIDM-02014: 15kW Traction Inverter Reference Design

Oct 2, 2024 · Part Number: TIDM-02014 Tool/software: Hello E2E Experts, Good day. Do we have a 15kW, 48V inverter for 3 wheeler application? If none, is there any way to

48V Solar Inverters: 2025 Buyer''s Guide & Top

Apr 3, 2025 · A 48V solar inverter converts direct current (DC) generated by solar panels into alternating current (AC), specifically designed for 48V battery

48-V, 10-A, High-Frequency PWM, 3-Phase GaN Inverter

Apr 3, 2017 · Description Low-voltage, high-speed drives and low-inductance brushless motors require higher inverter switching frequencies in the range of 40 kHz to 100 kHz to minimize

48-V Three-Phase Inverter With Shunt-Based In-Line

Apr 7, 2017 · The TIDA-00913 reference design realizes a 48-V/10-A three-phase GaN inverter with precision in-line shunt-based phase current sensing for accurate control of precision

48V, 3.5kW Small Form-Factor Three-Phase Inverter

Aug 2, 2024 · This reference design demonstrates a three-phase inverter with nominal 48V DC input and 85Arms output current rating. The 100V intelligent half-bridge gate driver DRV8162L

Motor control/inverter reference design targets

Aug 27, 2020 · The 48V mobility winning combination solution is powered from a 25 AHr Li-ion battery that drives a 1600W inverter to attain speeds up to 5000

Update Information

- What kind of inverter is used for 48v

- Tanzania inverter 48v to 220v inverter

- Does solar charging 48v require an inverter

- Is a 48v inverter better than a 12v one

- 48V inverter voltage regulation protection

- Photovoltaic inverter home decoration design

- Photovoltaic inverter design example

- 48v inverter price in Vilnius

- 48v and 60v use the same inverter

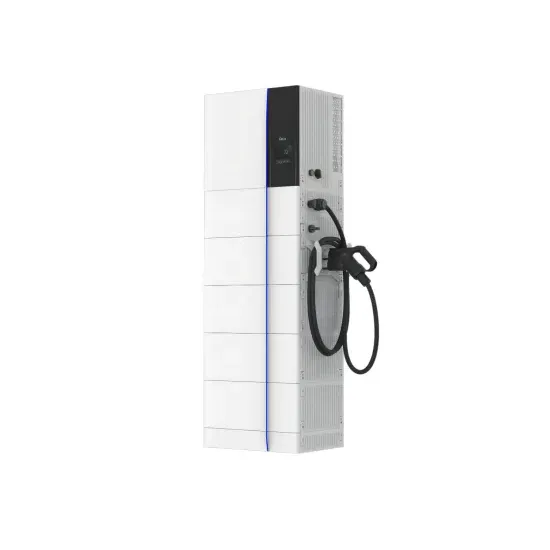

- 48v inverter with charging

- Design of grid-connected inverter operation

- Warsaw 48v inverter 12v to 220

- Three-phase inverter lc design

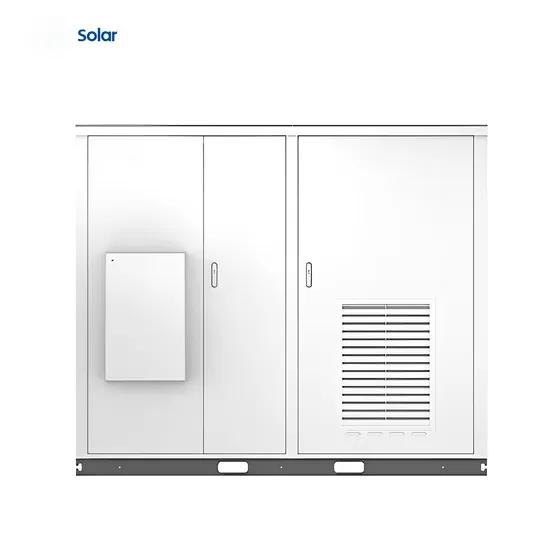

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.