Bt Communication Seperate Port Battery Management System BMS for Power

Jul 18, 2025 · * Support standard tower power replacement, mainstream cabinet control protocol; * Support 4G communication, can connect to the background real-time detection of battery

DC powerline communications for management of high

Apr 25, 2024 · Abstract High voltage battery packs consist of a large number of individual rechargeable cells. As such, they are extremely expensive and their tight manament is of

Power Cabinets Battery Management System BMS with 4G Communication

Jun 30, 2025 · * Support standard tower power replacement, mainstream cabinet control protocol; * Support 4G communication, can connect to the background real-time detection of battery

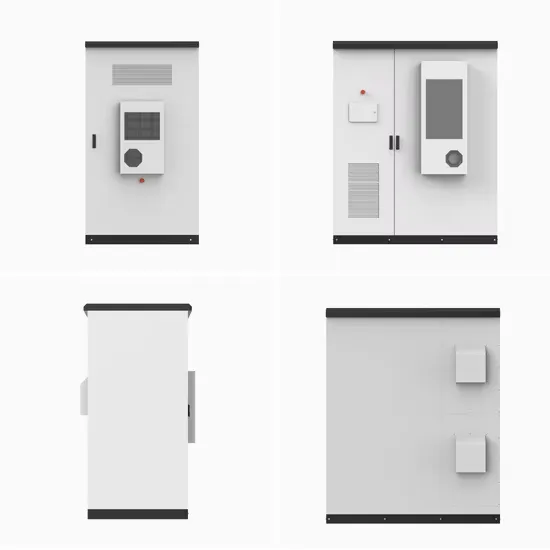

Energy storage high voltage cabinet structure

Voltage Outdoor Cabinet Up to 4 MWh Scalable rack cabinet configuration comprises several battery modules with. a dedicated battery energy management system. Lithium-ion batteries

High Voltage Battery Cabinet: Reliable Energy Storage

Jul 9, 2025 · This type of High Voltage Battery Cabinet provides the reliability and versatility needed to power manufacturing facilities and support entire city-wide energy grids, truly

Communication Protocol Reference Guide

Sep 12, 2023 · The Nuvation BMSTM is an enterprise-grade battery management system with support for various external communication protocols like Modbus RTU, Modbus TCP, and

High Voltage Battery Cabinet: Innovative Energy Storage

Jul 9, 2025 · High Voltage Battery Cabinet powers energy independence with advanced storage and intelligent management.As the world transitions towards renewable energy sources like

High Voltage Battery Cabinet by Hicorenergy: Secure Power

Jul 9, 2025 · The true innovation within a High Voltage Battery Cabinet lies in its internal engineering. A look inside Hicorenergy''s advanced rack-style solutions reveals the meticulous

Self-Adaptive and Optimal SOC Balancing Control for High Voltage

Apr 1, 2025 · State of charge (SOC) balancing is significant for high voltage transformerless (HVT) battery energy storage system (BESS) to utilize their full energy capacity

How to design an energy storage cabinet: integration and

Jan 3, 2025 · This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Energy storage high voltage cabinet structure

Energy storage secondary main control, real-time monitoring of battery cluster voltage, current, insulation and other status, to ensure high-voltage safety in the cluster, power on and off and

SmartLi 3.0 ST Datasheet

Dec 31, 2024 · Simple Active current balance control, supporting new and old battery cabinets mixed using, flexible to expand Smart active voltage balance control, Battery strings of

High Voltage Battery Cabinet: Top Energy Solution

Jul 9, 2025 · A High Voltage Battery Cabinet is the central hub for Industrial Battery Management, offering unprecedented control and oversight. Equipped with intuitive monitoring interfaces,

PowerPoint 演示文稿

Mar 1, 2024 · Simple Active current balance control, supporting new and old battery cabinets mixed using, flexible to expand Smart active voltage balance control, Battery strings of

ESS-GRID Cabinet Brochure EN-250106

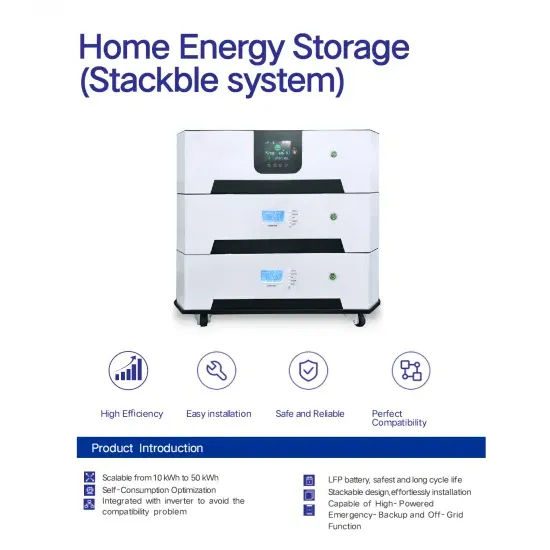

Jan 6, 2025 · Integrated Turnkey C&I ESS Solution The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent

Mate Outdoor Liquid Cooling High Voltage Lithium Battery Cabinet

Key attributes Battery Type Lithium Ion Grid connection Off grid, Hybrid grid Model Number WallArk Brand Name Matesolar Place of Origin Anhui, China Communication Port

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · Standardized communication protocols and interfaces, such as BMS compatibility: formulate a unified BMS (battery management system) communication protocol to support

Designing high cell count automotive applications with

Sep 29, 2023 · Using an optimized, unique daisy chain communication protocol, the battery monitors can be stacked up to support various battery pack sizes. Cheapest solution, but

Stackable Battery Management Unit Reference Design

Oct 12, 2023 · Description This reference design is a full cell-temperature sensing and high cell-voltage accuracy Lithium-ion (Li-ion), lithium iron phosphate (LiFePO4) battery pack (32s). The

Communication cabinet | Reliable Power Management

The communication cabinet adopts a standard cabinet and modular structural design, integrating functions such as system data collection, real-time monitoring, system lightning protection, grid

High Voltage Battery Cabinet for modern energy.

Jul 9, 2025 · The true performance of a High Voltage Battery Cabinet lies in its internal engineering and meticulous assembly. The advanced rack systems offered by Hicorenergy

6 FAQs about [Battery cabinet communication high voltage power balance]

Why is a battery management system important?

This translates into making the battery packs lower cost with higher energy densities. Every single watt-hour stored and retrieved from the cells is critical to extend the driving range. The main function of a battery management system (BMS) is to monitor cell voltages, pack voltages and pack current.

How is high voltage measured in a BJB?

High-voltage Measurements inside the BJB Voltage: The high-voltage is measured using divided-down resistor strings. These voltage measurements monitor the state of high-voltage components in the system.

Why do we need a battery pack monitor?

The massive electrification efforts happening in the automotive industry are driving the need to reduce the complexity of BMS by adding electronics in the junction box, while enhancing system safety. A pack monitor can locally measure the voltages before and after the relays, the current through the battery pack.

What is a battery management unit (BMS)?

Figure 1 presents a typical BMS architecture containing a battery management unit (BMU), cell supervisor unit (CMU) and a battery junction box (BJB). A BMU typically has a microcontroller (MCU), which manages all of the functions within the battery pack.

What are the features of a LFP battery?

Especially for LFP batteries where there is an extremely flat discharge profile. Built-in front end filter for each cell voltage input to reduce high frequency noise before ADC conversion. Dedicated Bulk Current Injection (BCI) filter to ensure measurement accuracy even in presence of common mode noise such as from the AC motor or inverter.

How do ti battery monitors maintain a time relationship?

TI’s battery monitors can maintain a time relationship by issuing an ADC start command to the cell monitor and the pack monitor. These battery monitors also support delayed ADC sampling to compensate for the propagation delay when transmitting the ADC start command down the daisy-chain interface.

Update Information

- New Energy Communication High Voltage Battery Cabinet

- Communication high voltage energy storage battery cabinet manufacturer

- New Energy Battery Cabinet Communication Power Solution

- Price of battery cabinet in communication power supply factory

- Cook Islands outdoor communication battery cabinet power

- High voltage cabinet can use UPS uninterruptible power supply

- Budapest liquid-cooled energy storage battery cabinet communication power supply

- Solar communication base station China high and low voltage distribution cabinet price

- How to install photovoltaic communication battery energy storage cabinet

- How to customize battery cabinet power supply

- Alofi Photovoltaic Communication Site Energy Battery Cabinet 72v

- Netherlands communication base station lead-acid battery cabinet manufacturer

- Battery cabinet output power

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.