Energy storage power station grid cabinet

What type of batteries are used in energy storage cabinets? Lithium batterieshave become the most commonly used battery type in modern energy storage cabinets due to their high energy

Battery capacity cabinet parameter settings

When the battery SOC drops to 0%, charge the batteries in a timely manner. If the batteries are not charged in a timely manner, the battery capacity will attenuate irreversibly. The resulting

An optimal dispatch strategy for 5G base stations equipped with battery

The escalating deployment of 5G base stations (BSs) and self-service battery swapping cabinets (BSCs) in urban distribution networks has raised concer

What are the meanings of energy storage cabinet

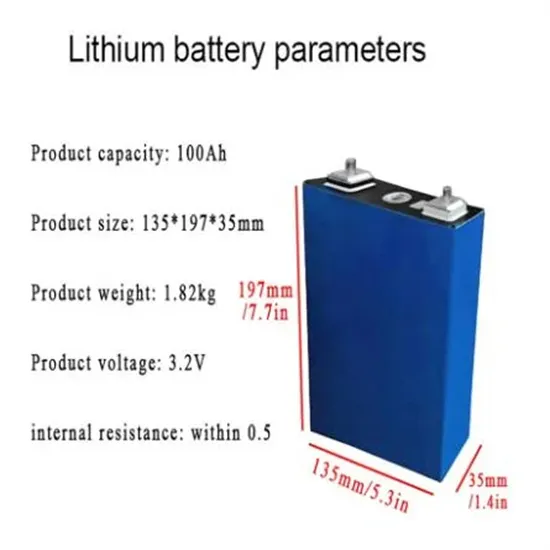

What are the parameters of a battery energy storage system? Several important parameters describe the behaviors of battery energy storage systems. Capacity[Ah]: The amount of

Accuracy requirements for battery aging cabinets in battery

Jun 30, 2025 · The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

General parameters of energy storage battery cabinet

The Optimal Parameters Matching of Hybrid Energy Storage Abstract: It is the consensus of the world that mass penetration of battery electric vehicles (BEVs) is the main solution to

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · VRLA Batteries have specific requirements for compliance with the building codes, fire codes, OSHA and may be subject to additional requirements from Authorities having

Energy storage cabinet related parameter table

About Energy storage cabinet related parameter table As the photovoltaic (PV) industry continues to evolve, advancements in Energy storage cabinet related parameter table have become

Lithium battery storage cabinet test parameters

Discover our specially-designed cabinets for lithium-ion battery storage. Engineered to prevent thermal runaway risks and fires, ensuring utmost safety for both people and goods. Protect

Battery Cabinet

Feb 28, 2025 · To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet

Battery capacity cabinet parameter settings

A Review on Design Parameters for the Full-Cell Lithium-Ion Batteries The lithium-ion battery (LIB) is a promising energy storage system that has dominated the energy market due to its

Battery storage cabinet parameter settings

When using the latest firmware on all compatible connected devices, and once the battery module has been detected by the GX device, battery charging parameters (e.g. Maximum Charge

Structural performance evaluation of mobile solar-powered battery

Dec 30, 2024 · This study introduces a structural design and static analysis of a Mobile Battery Swap Station for electric motorcycles, powered by solar energy, to address the critical need for

Battery energy storage cabinet technical parameters

Several important parameters describe the behaviors of battery energy storage systems. Capacity[Ah]: The amount of electric charge the system can deliver to the connected load

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Rechargeable Battery Cabinet Deployment for Public

Jul 29, 2022 · Zhigang Gao, and Siwen Zheng Abstract—Public Bike Systems (PBSs) offer the popular service for the short distance in daily life. The battery powered bike is an interesting

Specifications and requirements for battery cabinets in

o Battery rack/cabinet (if battery modules or Pre-assembled battery system requires external battery racks/cabinets for mechanical mounting/protection). o Balance of system components

6 FAQs about [Battery station cabinet parameter setting requirements]

Do you need a sign for a stationary battery system?

IFC 608.7; NPFA 52.3.8 Approved signs are required for Entrances to rooms and buildings with stationary battery systems of all technologies. Signs need to state the room has “energized battery systems, energized electrical circuits, the battery electrolyte solutions, where present are corrosive liquids.”

Do you need a barrier for a stationary battery system?

Instead, a standard barrier is recommended with the pads that contain less neutralizing absorbing compound. IFC 608.7; NPFA 52.3.8 Approved signs are required for Entrances to rooms and buildings with stationary battery systems of all technologies.

How is battery room compliance interpreted?

Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte and voltage present. Although the code is specific about requirements, the local interpretation can vary depending on the end users experience or awareness.

How should batteries be maintained?

Batteries should be maintained according to the manufacturer’s maintenance schedule and IEEE-1188 best practices. Approved devices should be used to measure and trend parameters to avoid a thermal runaway condition.

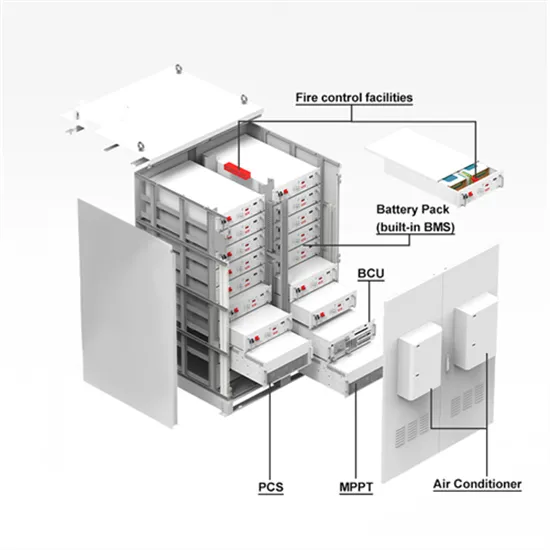

What is a battery management system?

The battery management system is considered to be a functionally distinct component of a battery energy storage system that includes active functions necessary to protect the battery from modes of operation that could impact its safety or longevity.

Do cabinets with VRLA batteries need a sign kit?

In addition, cabinets with VRLA batteries have a separate requirement to identify the details of the battery system, electrical, chemical and fire hazards. Remember New York City B-29 Certificate of Fitness requires a specialized sign kit for all five boroughs.

Update Information

- Requirements for power system of base station with battery cabinet

- Battery cabinet production line base station power generation requirements

- Lithium battery station cabinet base station energy and process

- Energy storage battery station cabinet

- Making a battery cabinet base station at home is real

- Battery cabinet phase change station cabinet

- Technical requirements for customized lithium battery station cabinets

- Replaceable lithium battery station cabinet photovoltaic communication

- Pretoria communication base station battery cabinet spot price

- DC screen battery cabinet base station

- Lisbon 72v lithium battery station cabinet

- Where to replace lithium battery station cabinet in Germany

- Lithium battery station cabinet charging cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.