Capacitor Replacement

Jan 24, 2020 · I''m pretty new to inverter repair. I have a Firestar (Voltronic from what I can work out) 3000VA 24V inverter that someone kindly connected 48v batteries to. They popped the

How to replace the capacitor of the inverter

Selecting dc-link capacitors for inverters Using a three-phase base power of √3V LINE I LINE = 9,880 VA results in per-unit capacitance values of C pu =3.36 for the electrolytic and 0.336 for

Nhx Series 48v Inverter User Manual-nfi | PDF | Power Inverter | Capacitor

Jun 20, 2025 · The N3H-X Series Hybrid Inverter user manual provides comprehensive instructions on installation, operation, and safety for qualified electricians. It covers essential

Replacement capacitor in inverter

May 2, 2023 · My Googling suggests the CCB22 are general purpose metallised polypropylene caps. Am I able to use a MKP cap such as the following as a replacement? Would rather a

Design of a 48 V three-phase inverter

Nov 25, 2022 · Abstract This project presents a design and construction of a three-phase inverter, drive circuit and dc-link capacitor bank. The inverter should be able to supply an electrical

Superwatt 5000W 48V repair

Jan 10, 2025 · I have currently an Superwatt 5000W 48 inverter out of service for repair at my lab. I have problems for rapairing the SMPS that failed. I have replaced all the caps, mosfets

Seeking advice regarding a spare 48V inverter to use if my

Jan 11, 2023 · However, it occurred to me that if the inverter ever has a fault and requires repair, how does a person in Australia obtain a replacement 48V inverter in a hurry? I''d have no

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

How to Replace the Battery of Your Photovoltaic Inverter

Let''s face it - your photovoltaic inverter''s battery is like the grumpy neighbor of your solar power system. You don''t think about it until the lights flicker during Netflix time. But here''s the kicker:

Will this work for pre-charging inverter capacitors?

Nov 2, 2019 · That will certainly do the pre-charge. Use a meter to watch the voltage rise the first time to gauge how long the button should be pressed. If

DC Link Capacitors Selection and Arrangement Procedure in

Dec 28, 2023 · The most important parasitic elements in high-power inverters are the ones associated with the DC-link and the capacitors used in its structure. This article will describe

48V systems: Driving power MOSFETs efficiently and

Aug 7, 2023 · In Peter Fundaro''s previous post on 48V automotive systems, he introduced a power-inverter system architecture and configuration as well as the design considerations for

Seeking advice regarding a spare 48V inverter to use if my

Jan 11, 2023 · I run a cheap inverter 24/7 in summer (a MUST EP3000, 6kW) to power my off-grid house, and have replacement parts for it if something goes wrong. In addition, I have a 3kVA

How to Install an AC Capacitor: A Step-by-Step

Jul 22, 2025 · Replace your AC unit''s run capacitor with our expert guide. Learn essential maintenance tips to keep your air conditioner running smoothly and

What is the cooling method of a 5kw 48v Inverter?

Our 5kw 48v Inverter Cooling Solution As a supplier of 5kw 48v Inverters, we understand the importance of effective cooling. Our inverters are designed with a combination of heat sink and

Interchanging / upgrading inverters

Jul 31, 2021 · While the electronics on the inverters would be new, the power circuit electric components, namely the transformer and main capacitor, would still be original. They are long

ECO-WORTHY 5000W 48V USER MANUAL Pdf Download

Adopt full digital voltage and current double closed-loop control and advanced SPWM technology to output pure sine wave. 2. Two output modes, i.e. mains bypass and inverter output can

Precharge with AC input?

Jun 8, 2022 · For a Multiplus II 3000/48v I plan to use a pushbutton with a 33 ohm/100 Watt resistor: Max DC Voltage: 3,65V x 16S = 58,4V Max power dissipation: 58,4 ^2 / 33 = 103 W

Life span and maintenance tips for photovoltaic

Nov 13, 2023 · The life of the inverter is determined by the shortest life components, usually IGBTs, capacitors, inductors, etc., and the service life is

Inverter Capacitor Pre-charging | DIY Solar

Mar 30, 2021 · That capacitor could carry 2300A for 1 millisecond, 23,000A for 0.1 millisecond charging to 48V. Energy 1/2 C V^2 = 56 joules (at 48V); this is

6 FAQs about [48v inverter capacitor replacement]

How many capacitors are on a Firestar 24V inverter?

I have a Firestar (Voltronic from what I can work out) 3000VA 24V inverter that someone kindly connected 48v batteries to. They popped the main capacitors on the inverter. There are 4 of them. They are 4200uf 35V electrolytic caps, which are not available locally as far as I can find.

Do DC-link capacitors increase inverter power?

DC-link capacitors can significantly contribute to this target by reducing parasitic losses and increasing thermal efficiency. High inverter powers can be theoretically achieved with multiple capacitor connections. However, a high number of parallel-connected parts also increase the complexity of the system stability.

Can DC-link capacitors reduce emissions?

High energy, reliable and volumetric efficient inverters are essential to reducing emissions of vehicles based on 48 V technology. DC-link capacitors can significantly contribute to this target by reducing parasitic losses and increasing thermal efficiency. High inverter powers can be theoretically achieved with multiple capacitor connections.

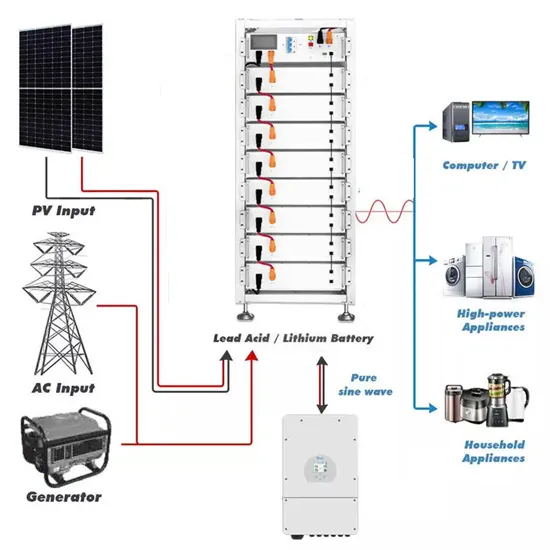

What are the components of a grid tie inverter?

Grid tie inverters require filter components in two key areas: The DC bus and AC output. The AC output filter is a low pass filter (LPF) that blocks high frequency PWM currents generated by the inverter. Three phase inductors and capacitors form the low pass filters.

What are axial hybrid polymer capacitors?

Axial Hybrid Polymer Capacitors are mainly targeted at higher power class 48 V inverters, for example, 15 kW and up, where the RMS ripple current for the DC-link capacitor bank is in the range of 150 Arms for continuous application and short periods can reach values of 300 Arms.

How long does a capacitor last?

You want at least 5000 h, preferably 10 000 h at 105°C. So something you get from a hobby electronics store is unlikely to work long term. Sure, any capacitor that is over 2 200 μF and physically fits will work for a week, but these capacitors protect the MOSFETs from spikes, so cheap capacitors will likely result in a loud bang within a year.

Update Information

- Central Africa DC inverter level capacitor

- 48v inverter price in Vilnius

- 48V inverter voltage regulation protection

- Tanzania inverter 48v to 220v inverter

- 48v to 22ov inverter

- Warsaw 48v inverter 12v to 220

- 48v inverter cost

- Inverter plus AC capacitor

- 500kw photovoltaic inverter capacitor quantity

- What kind of inverter is used for 48v

- Can the inverter 48v be converted to 60v

- 12v to 48v inverter output 220v

- Imported inverter 48v

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.