Solution of Mobile Base Station Based on Hybrid System of Wind

Mar 14, 2022 · The development of renewable energy provides a new choice for power supply of communication base stations. This paper designs a wind, solar, energy storage, hydrogen

Wind Energy Design and Fundamentals

Mar 15, 2023 · In terms of technology, turbine design focuses on optimizing power output by focusing on two key parameters: blade length and average wind speed. The latter is affected

How to make wind solar hybrid systems for telecom stations?

To provide a scientific power supply solution for telecommunications base stations, it is recommended to choose solar and wind energy. This will provide a stable 24-hour

Telecommunication base station system working principle

The ESB-series outdoor base station system utilizes solar energy and diesel engines to achieve uninterrupted off grid power supply. Solar power generation is the use of photovoltaic panels to

Optimal sizing of photovoltaic-wind-diesel-battery power

Mar 1, 2022 · Abstract The paper proposes a novel planning approach for optimal sizing of standalone photovoltaic-wind-diesel-battery power supply for mobile telephony base stations.

Optimal Control of the Green Low-Carbon Base

Jan 20, 2025 · This paper establishes an energy router system for green and low-carbon base stations, a −48 V DC bus multi-source parallel system including

Optimal sizing of photovoltaic-wind-diesel-battery power

Mar 1, 2022 · Amutha et al. analyzed and compared seven different configurations of hybrid power supplies for mobile base stations starting from a sole application of diesel generator to a

6 FAQs about [Base station power module wind power principle]

Can wind energy be used as power supply for BTS?

The wind speed at certain area (the test is conducted at the coast of Lhokseumawe, Aceh), which has wind speed that relatively strong whole day long, can generate electric energy of 50Ah, and charged the battery within 10.41 hours. It is shown that the wind energy can be used as power supply for BTS.

Can solar cells and wind turbines be integrated into BTS?

The result of the design and implementation of the hybrid system of solar cell and wind turbine proved that the energy produced within 10 hours that stored in the battery can be implemented into BTS.

How can a hybrid wind turbine and solar cell generate energy?

Therefore, due to fulfil the need of BTS, the energy can be supplied by a substitution of distributed generator (DG) such as wind turbine and solar cell. This research conducts by designing a hybrid of wind turbine and solar cell energy modules. These modules are able to generate 50 Ampere-hour of electric energy.

How much electricity does a PV/wind/battery hybrid system produce?

Monthly average electricity pro duction of PV/Battery hybrid system. 5.1.2. PV/Wind/Battery configuration are DC. The result is based upon the system w ith 41.4 kWh/day telecom load at 5.83 kWh/m solar radiation, 3.687m/s of wind speed and $0.8/L diesel price.

Can solar and wind provide reliable power supply in remote areas?

Solar and wind are available freely a nd thus appears to be a promising technology to provide reliable power supply in the remote areas and telecom industry of Ethiopia. The project aim generate and provide cost effective electric power to meet the BTS electric load requirement.

What is the difference between a PV panel and a wind turbine?

type voltage as backup, whereas the PV panels a nd wind turbine output is DC type. The converter is affect nature of the renewable s ources. Hybrid model of these three energy sources in parallel with uninterrupted power supply. Figur e 5 presents the schematic representation of HOMER simulation model considered. Figure 5.

Update Information

- Base station power supply 48v wind power supply principle

- 5g base station wind power module

- Base station power supply 48v wind power rectifier module

- Lisbon communication base station wind power design business

- 800M base station power supply wind power

- How many companies make up the communication base station wind power

- How is the wind power of communication base station set up

- How long will the wind power of the communication base station be disconnected if no one maintains it

- Communication base station wind power dv site

- Tunisia communication base station wind power equipment installation 6

- HJ mobile base station equipment wind power

- Outdoor wind power base station and wind power standard installation

- Airport materials outdoor base station wind power

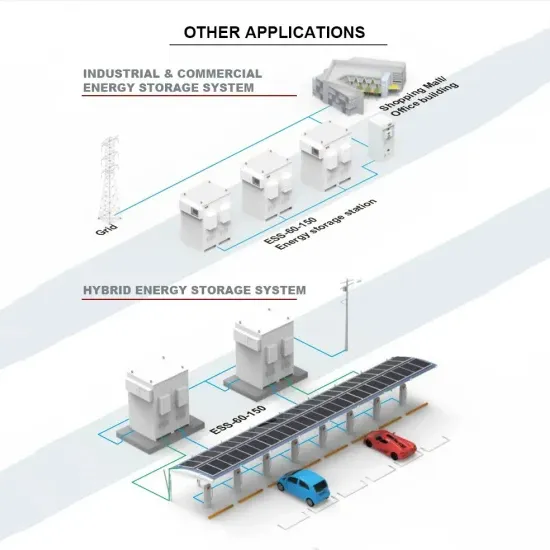

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.