VENTILATION SYSTEM OF ENERGY STORAGE CONTAINER AND ENERGY STORAGE

The energy storage container ventilation system of the present disclosure uses an air conditioner to dissipate heat. Ventilation plates are provided at communicating parts of the air duct and

A CFD based methodology to design an explosion

Jul 1, 2023 · This work developed a performance-based methodology to design a mechanical exhaust ventilation system for explosion prevention in Li-Ion-based stationary battery energy

Explosion protection for prompt and delayed deflagrations in

Dec 1, 2022 · Explosion hazards can develop when gases evolved during lithium-ion battery energy system thermal runaways accumulate within the confined space of an energy storage

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Lithium batteries are widely used in energy storage systems due to their advantages such as high energy density, large output power, low self-discharge rate, long

Lithium ion battery energy storage systems (BESS) hazards

Feb 1, 2023 · There has been an increase in the development and deployment of battery energy storage systems (BESS) in recent years. In particular, BESS using lithium-ion batteries have

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The HVAC system for a BESS container must be meticulously designed to achieve the desired temperature and air volume conditions. This involves the strategic placement of

Ventilation Volume Calculation for Energy Storage Containers

Summary: Proper ventilation design is critical for ensuring the safety and efficiency of energy storage systems. This guide explains how to calculate ventilation requirements for battery

Ventilation Volume Standards for Energy Storage Containers

This guide explores global ventilation volume standards, calculation methods, and best practices to prevent thermal runaway in battery containers. Discover how to balance safety, efficiency,

Energy storage container ventilation calculation

If you''''re looking to combat excessive moisture inside your 10 foot Storage Container, 20 foot Storage Container, 40 foot container or 40? high cube container, we offer Louvered vents,

ventilation volume calculation for energy storage container

Fundamentals of high-temperature thermal energy storage, transfer The storage duration is commonly in the range of minutes to hours for the temperature above 300°C. The different

Ventilation Requirements for Energy Storage Containers

This article explores key ventilation strategies, industry best practices, and real-world case studies to help engineers and project managers optimize their energy storage solutions.

Numerical investigation on explosion hazards of lithium-ion

Nov 1, 2023 · It was based that the TR propagation of battery energy storage unit occurs, releasing flammable gas that accumulated inside the container over time to form a premixed

Energy storage container ventilation calculation

To ensure a suitable operating environment for energy storage systems,a suitable thermal management systemis particularly important. If you''''re looking to combat excessive moisture

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Safety Conditions in Battery Rooms for Renewable

Nov 25, 2024 · Batteries used for electrical energy storage must be installed in enclosed enclo-sures that comply with the relevant regulations. This will ensure safety for personnel and

Thermal equalization design for the battery energy storage

Dec 15, 2024 · The Battery Energy Storage System (BESS), as the primary power source for electric ships, must maintain its temperature within an appropriate range to ensure safe

Effect of ambient pressure on the fire characteristics of

Dec 1, 2024 · As lithium-ion battery energy storage gains popularity and application at high altitudes, the evolution of fire risk in storage containers remains uncertain. In this study,

Ventilation volume standard for energy storage containers

An ideal ventilation option for shipping containers is "balanced ventilation" — this uses both an extractor fan and a supply ventilation system for optimal results. Foundation Vents Foundation

Analysis of hydrogen leakage characteristics and hazard

Jun 18, 2025 · To save calculation time, steady-state simulation is used in this study regarding the effects of parameters such as inlet and outlet locations, the longitudinal ventilation air volume

Paper Title (use style: paper title)

May 13, 2024 · Bernard.dabe@vigilexenergy Abstract—This presentation is talking about safety for energy stationary storage systems (BESS) with lithium-ion batteries and covers

6 FAQs about [Energy storage container ventilation volume]

Can a battery container fan improve air ventilation?

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized system for the development of a healthy air ventilation by changing the working direction of the battery container fan to solve the above problems.

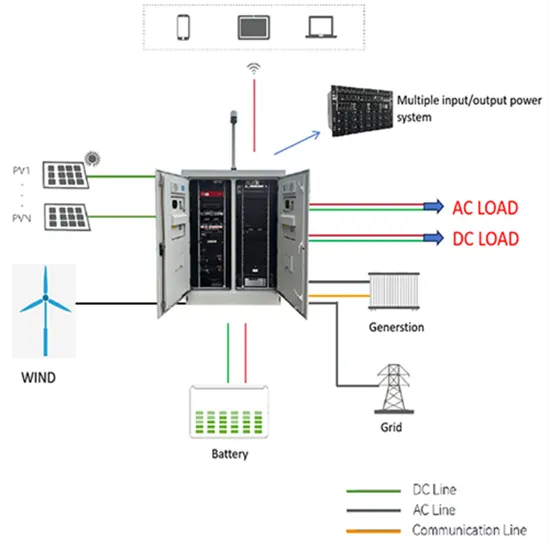

What is a battery energy storage system?

The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these systems, one key element that ensures their efficient and safe operation is the Heating, Ventilation, and Air Conditioning (HVAC) system.

What is energy storage system (ESS)?

The energy storage system (ESS) studied in this paper is a 1200 mm × 1780 mm × 950 mm container, which consists of 14 battery packs connected in series and arranged in two columns in the inner part of the battery container, as shown in Fig. 1. Fig. 1. Energy storage system layout.

Does airflow organization affect heat dissipation behavior of container energy storage system?

In this paper, the heat dissipation behavior of the thermal management system of the container energy storage system is investigated based on the fluid dynamics simulation method. The results of the effort show that poor airflow organization of the cooling air is a significant influencing factor leading to uneven internal cell temperatures.

How do I ensure a suitable operating environment for energy storage systems?

To ensure a suitable operating environment for energy storage systems, a suitable thermal management system is particularly important.

How to improve airflow in energy storage system?

The aim of this strategy is to improve the fan state at the top so that the entire internal airflow of the energy storage system is in a circular state with the central suction and the two blowing ends. Optimized solution 4: fans 3 and 9 are set to suction state and the rest of the fans are set to blow state.

Update Information

- 1mw container energy storage power station volume

- What is the volume of a 1MW base station container energy storage power station

- Yaounde container energy storage system manufacturer

- What brands of energy storage container manufacturers are there

- Energy storage container solar photovoltaic module factory photothermal equipment

- Which standard should energy storage container refrigeration meet

- Energy storage container system installation requirements

- United Arab Emirates Container Energy Storage System Company

- Micronesia container energy storage cabinet manufacturer

- Eastern European container energy storage cabinet manufacturers

- Energy storage container cooperative design plan

- Which companies need energy storage container equipment

- Photovoltaic power station energy storage container manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.