Flame Propagation Between Flat Roofing and

Jun 30, 2021 · Flame Propagation Between Flat Roofing and Photovoltaic Installations By Farah Binte Mohd Faudzi Supervised by Prof. Grunde Jomaas Special thanks to Jens Steemann

Providing Access to Roofs with a PV System | NFPA

Jul 24, 2020 · Accessways for roof-mounted photovoltaic systems ensure firefighter safety and efficient operations during emergencies, adhering to NFPA standards.

Photovoltaic Array Row Spacing Calculator

The row spacing of a photovoltaic array is the distance between the front and rear rows of solar panels. This spacing is calculated to ensure that the rear panels are not shaded by the front

Calculate distance between rows of photovoltaic panels (In

Jan 15, 2025 · Roof A inclination (south) Roof B inclination (north) Tilt angle Roof Latitude Panel Length (Height) Angle of panel above Horizontal Minmum distance F1aP2 Recomended

How Close Can Solar Panels Be To Edge Of Roof?

Jan 9, 2023 · There are a few things to consider when determining how close solar panels can be to the edge of a roof. First, most jurisdictions have a minimum set-back requirement from the

Photovoltaic panel roof support distance

Considering that most solar panels are 5.5 feet x 3.25 feet and occupy roughly 20 square feet,the typical roof -which usually covers 1,600 square feet - can theoretically accommodate 80 solar

Solar photovoltaic panel installation distance

At its core,understanding solar panel spacing is about grasping the balance between maximizing energy absorption and minimizing shading losses. The spacing between panels determines

How much gap should be left between photovoltaic panels

two rows of solar panels should be five to s. x inches. This is how far apart should solar panels be. It is also recommended that you leave. 1 to 3 feet of space between every second or third row.

Building standards

Sep 20, 2018 · The photovoltaic (PV) roof mounted solar panels are located above concrete roof tiles with an external fire exposure classification of Broof (t4) and a reaction to fire classification

THE GRO BIOSOLAR BEST PRACTICE DESIGN GUIDE

Jul 18, 2024 · Purpose-made support frame systems for PV panels on green roofs have been developed and these are designed to be integral to the green roof and secured in place by the

How much gap should be left between photovoltaic panels

Talking about the gap between solar panels and the roof,the distance between the last row of solar panels and the edge of the roof should be a minimum of 12 inches. This ensures the

The distance between photovoltaic panels in the sun room

The distance between two rows of solar panels should be five to six inches. This is how far apart should solar panels be. It is also recommended that you leave 1 to 3 feet of space between

Calculation of shading distance of photovoltaic panels

Dec 30, 2020 · The parameters of the solar panel: the tilt angle is v = 35 o, the relative row distance (i.e., the ratio of the row distance to the tilted width) is d = 1.5. But in addition to these

Fire Safety Guideline for Building Applied Photovoltaic

Jun 10, 2024 · a PV-related fire compared to roofing fire without a PV system. The following points explain in more detail how the choosing and placement of solar panels and elements around

Slope, pitch, gradient of a roof or solar panels (calculator

Nov 14, 2024 · Calculator and relationship between slope, pitch, gradient, rise, run length and tilted length of a roof or solar photovoltaic panels Free online calculator of the slope according

6 FAQs about [Photovoltaic panel roof distance]

What is the row spacing of a photovoltaic array?

where: The row spacing of a photovoltaic array is the distance between the front and rear rows of solar panels. This spacing is calculated to ensure that the rear panels are not shaded by the front panels, maximizing the efficiency of the solar array. Let's assume the following values: Using the formula:

How far away should solar panels be from the roof?

However roof-mounted solar installations must also be more than 30cm away from the external edge of the roof, meaning that actually you will need an even larger space so this needs to be factored in to any roof sizing calculations. Your panels will need to be positioned on a South (or South-East to South-West) facing roof.

How much space should be between two solar panels?

There should be at least 4 to 7 inches of space between two rows of solar panels, to allow for proper passage in case of installation and maintenance. There should also be a centimeter-grade distance between two adjacent solar panels (the outer frame) in each row, as the panel frame contracts and expands with the weather.

How far should roof panels be from roof edge?

Leave enough space between panels and the roof edge for installation, maintenance, and safety, with a recommended minimum distance ranging from 6 inches to 2 feet. Ensure easy access for cleaning, inspections, and repairs by maintaining a safe distance from the roof edge.

How much space does a rooftop solar PV system need?

Based on the above, we can see that a rooftop solar PV system typically requires 100 SF (about 10 m 2) of shade-free roof area per kW of capacity. [youtube_popup] Rooftop solar PV plants are fairly heavy (about 30-60 Kgs/m 2 ). They do not pose a problem for concrete roofs but cannot be installed on asbestos roofed sheds.

How far can solar panels stay from a house?

Solar arrays can only stay a certain distance from the house before performance suffers, as is module spacing. Both the solar panel frame and the glass covering the battery are durable, but they don't bump into each other. Modules can also get quite hot depending on the weather, so make sure you have enough clearance between them.

Update Information

- Photovoltaic panel roof weak current installation

- Ground roof photovoltaic panel installation

- How much does the photovoltaic panel on the roof of Sofia cost

- 550w photovoltaic panel roof installation

- How much does the photovoltaic panel on the roof of Basseterre cost

- Kinshasa glass roof photovoltaic

- Brunei rooftop photovoltaic panel manufacturer

- Kenya photovoltaic panel 220v home complete set

- Morocco special price photovoltaic panel manufacturers

- Photovoltaic panel prices in Greece

- Shopping mall photovoltaic panel manufacturers

- 340W monocrystalline photovoltaic panel

- Tuvalu photovoltaic panel manufacturers

Solar Storage Container Market Growth

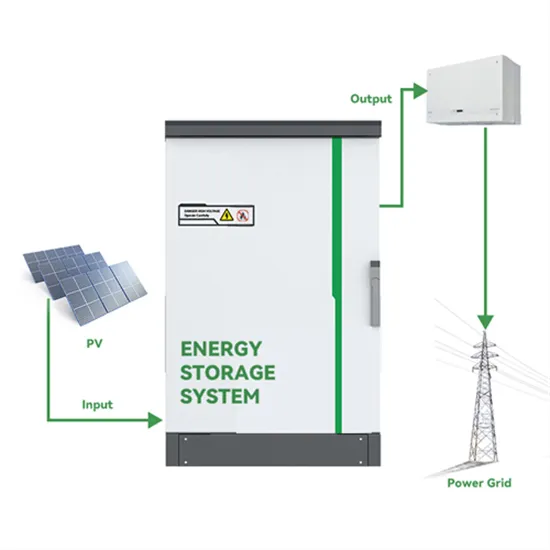

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.