Energy storage system of communication base station

Energy storage system of communication base station Base station energy cabinet: floor-standing, used in communication base stations, smart cities, smart transportation, power

2024-2030全球与中国通信基站用锂电池市场现状及未来发展趋势

2024-2030 Global and China Lithium Battery for Communication Base Stations Market Status and Forecast 报告编码: qyr2404221027288 服务方式: 电子版或纸质版 电话咨询: +86-176 7575

Selection and maintenance of battery for communication base station

Mar 30, 2025 · Focused on the engineering applications of batteries in the communication stations, this paper introduces the selections, installations and maintenances of batteries for

Telecom Site Battery Backup-Product-BESCOM Battery

Lithium-ion batteries will gradually become the first choice for high-end backup power solutions. BESCOM base station lithium battery module is widely used in communication base stations

Lithium-ion Battery For Communication Energy Storage System

Aug 11, 2023 · Lithium-ion Battery For Communication Energy Storage System The lithium-ion battery is becoming more and more common in our daily lives. This new type of battery can

Energy storage system of communication base station

The Energy storage system of communication base station is a comprehensive solution designed for various critical infrastructure scenarios, including communication base stations, smart

Communication Base Station Energy Power Supply System

The wind-solar-diesel hybrid power supply system of the communication base station is composed of a wind turbine, a solar cell module, an integrated controller for hybrid energy

Selection and maintenance of battery for communication base station

Mar 30, 2025 · Abstract: Battery is a basic way of power supply for communications base stations. Focused on the engineering applications of batteries in the communication stations, this paper

Communication base station battery maintenance equipment

Mar 12, 2019 · This configuration, which was originally named "Battery Detector" and participated in the battery maintenance scale, has been widely deployed by the communications industry to

COMMUNICATION BASE STATION-en spowers

High safety lithium iron phosphate/sodium ion cell is used. Highly integrated, lightweight, standardized, intelligent control. 48V10Ah-200Ah adapting to all scenarios. Integrated BMS

Battery Management System for Communication Base Stations

Why do communication base stations use battery energy storage? Meanwhile, communication base stations often configure battery energy storage as a backup power source to maintain the

China High Quality Communication Base Station Suppliers

Dec 1, 2024 · The Communication Base Station is a versatile device that acts as a wireless repeater, enhancing the range and quality of communication signals. It is designed to be

Introduction to Communication Base Station Batteries

What is the traditional configuration method of a base station battery? The traditional configuration method of a base station battery comprehensively considers the importance of the 5G base

Maintenance of communication base station power supply

At present, most of the main equipment in mobile base stations (hereinafter referred to as base stations) in the communication industry rely on DC uninterruptible power supply systems to

ICTRFN4177A Install radio communications base station

Apr 8, 2024 · Application of the unit Field officers from private or public organisations apply the skills and knowledge in this unit. They combine technical radio communications skills with

Battery repair for communication base station

Telecom base station battery is a kind of energy storage equipment dedicatedly designed to provide backup power for telecom base stations, applied to supply continuous and stable

Selection and maintenance of batteries for communication base stations

This article focuses on the engineering application of the battery in the power supply system of the communication base station, and focuses on the selection, installation and maintenance of the

New technology for backup batteries in communication base stations

Backup Battery Analysis and Allocation against Power Outage for Cellular Base Stations paper, we closelyexamine the base station features and backup battery features from a 1.5-year

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

5 FAQs about [Communication base station battery equipment installer 04]

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

Which battery is best for telecom base station backup power?

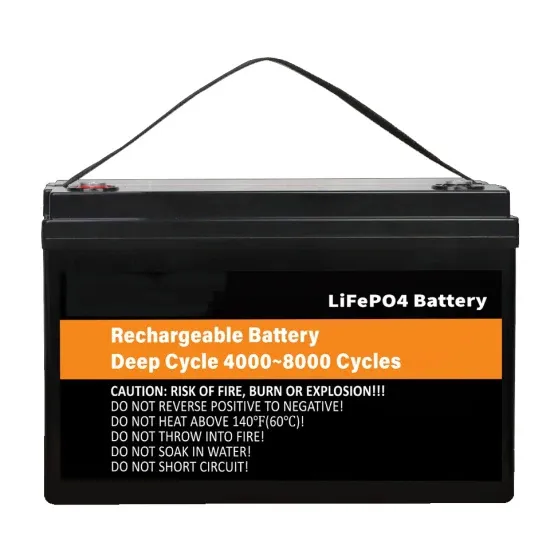

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

How do you protect a telecom base station?

Backup power systems in telecom base stations often operate for extended periods, making thermal management critical. Key suggestions include: Cooling System: Install fans or heat sinks inside the battery pack to ensure efficient heat dissipation.

What is a battery management system (BMS)?

Battery Management System (BMS) The Battery Management System (BMS) is the core component of a LiFePO4 battery pack, responsible for monitoring and protecting the battery’s operational status. A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging.

What makes a good battery management system?

A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging. Temperature Management: Built-in temperature sensors to monitor the battery pack’s temperature, preventing overheating or operation in extreme cold.

Update Information

- Kazakhstan Communication Base Station Battery Energy Storage System Equipment Processing Factory

- Battery energy storage system equipment maintenance at Gitega communication base station

- Vienna communication base station flow battery equipment manufacturer

- Is the flow battery room of a communication base station considered equipment

- Kingston Communication Base Station Battery Equipment Price

- Liquid flow battery for 5G communication base station in Windhoek

- Communication base station flow battery range

- Calculation formula for the battery life of a communication base station lithium battery

- Communication base station battery testing manufacturer

- How does base station communication equipment transmit data

- Ghana communication base station battery energy storage system safety distance

- 2 Carrier frequency 800m digital trunking communication base station battery energy storage system

- Kathmandu outdoor communication battery cabinet quotation and base station

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.