Current Challenges in Efficient Lithium‐Ion

Sep 8, 2022 · Li-ion battery (LIB) recycling has become an urgent need with rapid prospering of the electric vehicle (EV) industry, which has caused a shortage

A review of new technologies for lithium-ion battery treatment

Nov 15, 2024 · Spent lithium-ion batteries (S-LIBs) contain valuable metals and environmentally hazardous chemicals, necessitating proper resource recovery and harmless treatment of these

Challenges and opportunities toward long-life lithium-ion batteries

May 30, 2024 · Following this, the degradation modeling and advanced management strategies for achieving long-life batteries are elucidated. Lastly, facing the existing challenges and future

Questions and Answers Relating to Lithium-Ion Battery Safety Issues

Jan 20, 2021 · The issues addressed include (1) electric vehicle accidents, (2) lithium-ion battery safety, (3) existing safety technology, and (4) solid-state batteries. We discuss the causes of

Ten major challenges for sustainable lithium-ion batteries

Jun 19, 2024 · Lithium-ion batteries offer a contemporary solution to curb greenhouse gas emissions and combat the climate crisis driven by gasoline usage. Consequently, rigorous

Opportunities and Challenges in Lithium-Ion Battery

Feb 22, 2025 · The implementation of the EU Critical Raw Materials Act and the Battery Regulation is expected to significantly advance LIBs recycling efforts, creating new

Advances in sodium-ion batteries at low-temperature:

Mar 1, 2024 · Despite the advancements in many other beyond-Li technologies, such as K and Mg-ion batteries, SIBs offer the best performance, cost-effectiveness, and scalability, and

Challenges and industrial perspectives on the development of sodium ion

Oct 1, 2024 · The ever-increasing energy demand and concerns on scarcity of lithium minerals drive the development of sodium ion batteries which are regarded as pro

The latest research on the pre-treatment and recovery

Dec 8, 2023 · The vigorous development of new energy vehicles, as well as the promotion policy and market, has made China the world''s leading producer and consumer of lithium-ion

Direct recycling of spent Li-ion batteries: Challenges and

Sep 15, 2023 · With the exponential expansion of electric vehicles (EVs), the disposal of Li-ion batteries (LIBs) is poised to increase significantly in the coming years. Effective recycling of

Environmental Impact of Lithium-Ion Batteries: What You

Feb 11, 2025 · Lithium-ion batteries are an integral part of our modern lives, powering everything from smartphones and laptops to electric vehicles and renewable energy systems. While these

Understanding materials failure mechanisms for the

Mar 20, 2025 · Lithium-ion batteries suffer from complicated degradation behaviours, posing challenges for recycling. This Review explores the failure mechanisms in state-of-the-art

Understanding materials failure mechanisms for the

Mar 20, 2025 · In this Review, failure mechanisms in state-of-the-art LIBs are discussed from the particle scale to the cell scale, offering insights for navigating recycling efforts.

Advancements and challenges in solid-state lithium-ion batteries

May 14, 2024 · Despite these advantages, several obstacles still hinder their widespread adoption. This review focuses on the lithium-ion conductors and their complex ion conduction

Electrode materials for lithium-ion batteries

Dec 1, 2018 · In recent years, the primary power sources for portable electronic devices are lithium ion batteries. However, they suffer from many of the limitations for their use in electric

Surface-treating insights for the various substrates used in lithium

Feb 3, 2025 · Surface treatment enables proper coating adhesion, which allows the batteries to perform as designed. This article will review important criteria for successful surface treating

Current Challenges in Efficient Lithium‐Ion

Sep 8, 2022 · Technical difficulties include evaluating and testing the SoH of spent batteries, setting technical standards based on different designs since

Clearing surficial charge-transport obstacles to boost the

Nov 1, 2020 · The interfacial property of cathode materials in Li-ion batteries plays a vital role for the mass transport in electrochemical process. In this paper,

Electrolytes in Lithium-Ion Batteries: Advancements in the

Feb 1, 2024 · Solid-state batteries exhibited considerable efficiency in the presence of composite polymer electrolytes with the advantage of suppressed dendrite growth. In advanced polymer

Comprehensive review and comparison on pretreatment of spent lithium

Jul 1, 2024 · Pretreatment, the initial step in recycling spent lithium-ion batteries (LIBs), efficiently separates cathode and anode materials to facilitate key element recovery. Despite brief

Progress and challenges in using sustainable carbon anodes

Nov 1, 2021 · Open access Abstract Rechargeable lithium-ion batteries (LIBs) are one of the most promising alternatives to effectively bypass fossil fuels. However, long-term energy application

Obstacles to the development of lithium batteries-EEWORLD

Lithium-ion batteries also have many defects: short cycle life, complex charging circuit, and high requirements for internal battery protection circuits. Especially for lithium-ion batteries

Intensification of lithium carbonation in the thermal treatment

May 1, 2023 · The recycling of lithium-ion batteries remains an essential question, the recovery of lithium is a central matter since the European Commission identified it as a critical raw

Future Prospects and Challenges of Lithium-Ion

Dec 18, 2024 · Innovators are actively addressing the challenges facing Li-ion battery technology, from energy density and charging speeds to sustainability

FRONTIER TECHNOLOGY ISSUES LITHIUM-ION

Jul 8, 2021 · Li-ion batteries and significant price declines due to investment in productive capacity. It is the urgent and inescapable mandate for the entire humanity to reduce gree.

Life cycle assessment of secondary use and physical

Apr 15, 2024 · In this paper, the retired Electric vehicles lithium-ion batteries (LIBs) was the research object, and a specific analysis of the recycling treatment and gradual use stages of

Life Cycle Assessment of Lithium-ion Batteries: A Critical

May 1, 2022 · Evolving technological advances are predictable to promote environmentally sustainable development. Regardless the development of novel technologies including Li-ion

Electrochemical Approach for Lithium Recovery

Jul 2, 2024 · The challenges and opportunities of electrochemical methods in the field of lithium recycling from spent LIBs are presented and evaluated, from

Advances in lithium-ion battery recycling: Strategies,

Jan 1, 2025 · The use of lithium-ion batteries in portable electronic devices and electric vehicles has become well-established, and battery demand is rapidly incre

6 FAQs about [What are the obstacles to the treatment of lithium-ion batteries in communication base stations ]

How are innovators addressing the challenges facing Li-ion battery technology?

Innovators are actively addressing the challenges facing Li-ion battery technology, from energy density and charging speeds to sustainability and recycling. By actively overcoming these challenges, researchers are unlocking new possibilities for Li-ion batteries, enabling wider adoption in EVs, renewable energy systems, and beyond.

How will the EU critical raw materials act affect lithium-ion batteries recycling?

The implementation of the EU Critical Raw Materials Act and the Battery Regulation is expected to significantly advance LIBs recycling efforts, creating new opportunities for the recycling industry. Pre-treatment and pre-processing are critical steps in the recycling of lithium-ion batteries (LIBs) [4, 5].

Can membrane processes be used to recover lithium from batteries?

Classical technologies for recovering lithium from batteries are associated with various environmental issues, so lithium recovery remains challenging. However, the emergence of membrane processes has opened new research directions in lithium recovery, offering hope for more efficient and environmentally friendly solutions.

What is a lithium ion battery?

Lithium-ion (Li-ion) batteries are actively powering modern technology, driving portable electronics, electric vehicles (EVs), and renewable energy storage systems. As the world actively shifts toward more sustainable energy solutions, the role of lithium-ion batteries is expanding rapidly.

Why are lithium-ion batteries used in electric vehicles & energy storage stations?

In the backdrop of the carbon neutrality, lithium-ion batteries are being extensively employed in electric vehicles (EVs) and energy storage stations (ESSs). Extremely harsh conditions, such as vehicle to grid (V2G), peak-valley regulation and frequency regulation, seriously accelerate the life degradation.

Why is recycling used lithium ion batteries important?

To ensure the sustainability of both the LIBs and automotive industries, the recycling of spent LIBs is crucial. Recycling not only provides critical metals needed for the production of new batteries but also mitigates the environmental impacts associated with improper disposal of spent LIBs.

Update Information

- What are the regulations for the location of flow batteries in communication base stations

- What are the types of lead-acid batteries used in communication base stations

- The crux of the difficulty in generating power through lithium-ion batteries for communication base stations

- The evolution of lithium-ion batteries for communication base stations

- New quota for lithium-ion batteries for communication base stations in 2016

- What batteries are there in communication base stations

- What cables are used for flow batteries in communication base stations

- What are the flow batteries for Kiribati s high-altitude communication base stations

- What are the lithium battery cells for communication base stations

- What are the brands of solar energy for communication base stations

- The principle of lithium batteries used in communication base stations

- What type of grid-connected B inverter is for communication base stations

- Do communication network base stations have batteries

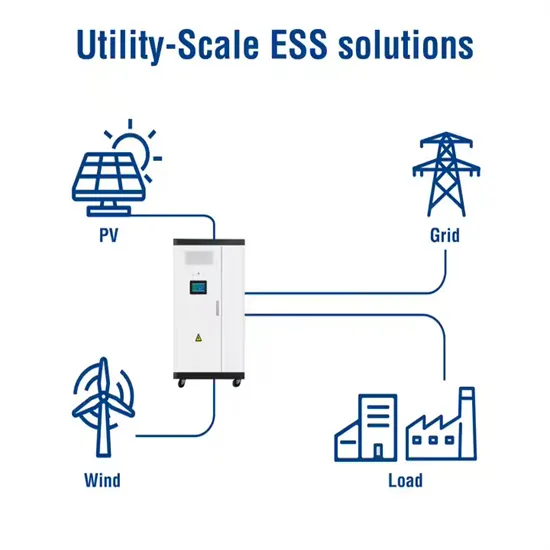

Solar Storage Container Market Growth

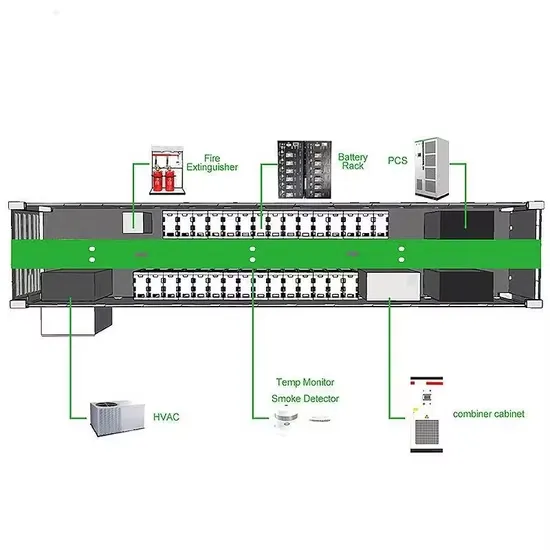

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

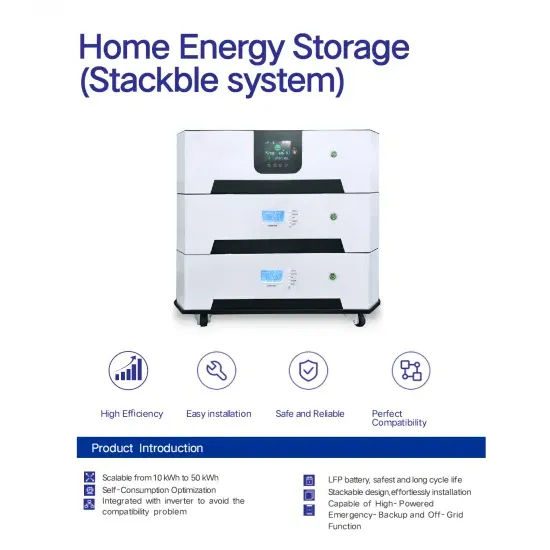

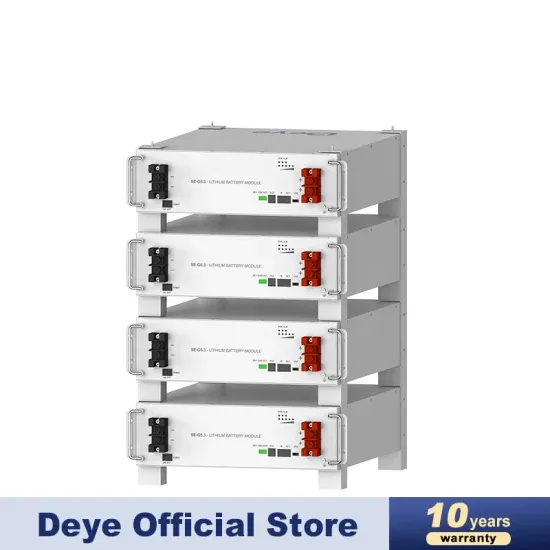

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.