Surge Protection for Cell Sites

Aug 14, 2023 · Tested surge protective devices (lightning current and surge arresters) shield the main and system power supply infrastructure. These arresters excel in handling follow currents

Research on Design of Switching Power Supply Based on Mobile Base Station

Jan 1, 2016 · Keywords: Mobile Base Station, Switching Power Supply, Control Circuit Abstract: With the rapid development of mobile communication service, the construction of mobile

Protection for an AC Power Supply in a Mobile

This Bourns® Power Play SolutionTM presents the power protection scheme for the AC input to a mobile transceiver power supply system. It will present the advantages of using Surge

Base station lightning protection system

The invention discloses a lightning protection system for a base station. The lightning protection system for a base station includes: a grounding bar connected to the ground wires of each

(PDF) Analysis of Lightning Protection and Grounding Effect

Aug 26, 2020 · By analyzing the lightning protection and grounding requirements of the respective systems of the communication base station and the power tower, the impact of the towers on

Design of mobile base station communication power supply

3) The mobile base station communication power supply system adds a comprehensive overvoltage protection circuit, and integrates lightning overvoltage protection and non-lightning

Research on lightning protection and earthing of radio base station

Sep 1, 2010 · Equipments and devices damaged by lightning strike in RBS include: power supply equipment accounting for 90% (transformers, power distribution boxes, regulators, rectifier

A complete 5G mobile base station power lightning protection

It generally includes the following four aspects: lightning protection of AC power cables, grounding connection between base station grounding network and station equipment, lightning

Protect mobile communication systems | DEHN

Our solutions for lightning and surge protection in the telecommunications sector not only protect equipment, power and data supply, but also – critically – your employees. And with the broad

Lightning Surge Protector-Lightning Surge Protector

The floor, computer center, telecommunications room, elevator control room, frequency conversion equipment control room, hospital operation room power distribution box, power

Protection for an AC Power Supply in a Mobile

Situation Telecom power supplies are typically powered by 48 VDC, but there is a growing trend where Base Transceiver Station (BTS) equipment is powered by 110/220 VAC. While it is

Lightning protection, earthing and surge protection of base

Dec 22, 2011 · An effective lightning protection design for a telecommunication facility requires an integrated approach to a number of key factors: Protection against direct

Lightning protection solutions for mobile base stations

Jun 28, 2020 · Most mobile base stations are built on high terrain, such as high mountains, suburbs, and buildings. The base station antennas are often higher than the existing lightning

Communication Base Station (Independent Station) Lightning Protection

This solution simplifies the complex base station ground network engineering by using the equipment method, and completely isolates the impact between lightning protection grounding,

How To Effectively Protect Electronic Systems In A Mobile Base-Station

Structural Lightning Protection alone will NOT prevent Surges damage. Effective Protection for the Sensitive Electronic Equipment contained in a cell site can be achieved by fitting Surge

6 FAQs about [Mobile base station equipment power supply lightning protection]

What is lightning & surge protection?

A thorough lightning and surge protection approach provides optimal safety for people and high availability systems. LSP designs specialized AC and DC Surge Protection Devices (SPDs) for mobile radio sites.

What is a lightning & surge arrester?

The cables from the energy supply and the backup power connect at the main distribution. Because strong lightning currents and overvoltages can occur in this part of the system, a compact device combination (type 1+2 special combined lightning current and surge arrester) is used for lightning and surge protection.

What is a type 1 Lightning current arrester?

This is why the standard DIN EN 62305 (IEC 62305) mandates a type 1 lightning current arrester at the boundary between lightning protection zone 0 B and 1. In mobile communication stations, this boundary typically aligns with the base station’s outlet.

Do mobile communication components need protection against lightning and overvoltage damage?

Mobile communication components, with their sensitivity and costliness in terms of procurement and upkeep, demand robust protection against lightning and overvoltage damage. A meticulously designed protection strategy is thus essential and advantageous in this context.

What is a cell site power supply?

In AC applications, cell site power supply is distinct from the building’s, forming a separate supply line. Tested surge protective devices (lightning current and surge arresters) shield the main and system power supply infrastructure.

Why do cell sites need to be protected from lightning strikes?

Cell sites are essential for communication infrastructure and need to be shielded from power surges caused by lightning hits. A major concern for telecom operators is towers going offline due to lightning strikes, which often target the tallest structures in a region.

Update Information

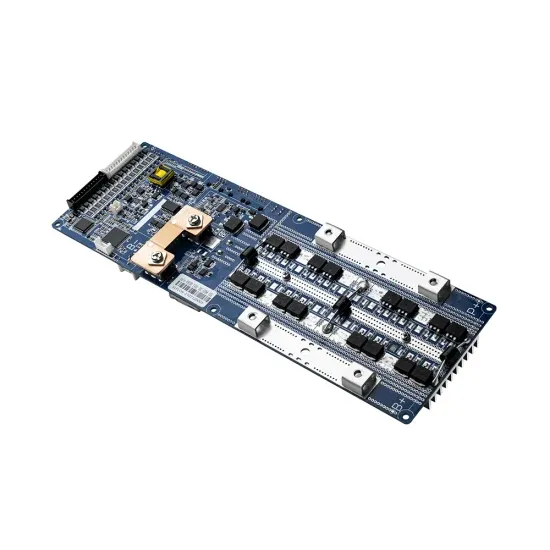

- Avalu Mobile Base Station Power Supply

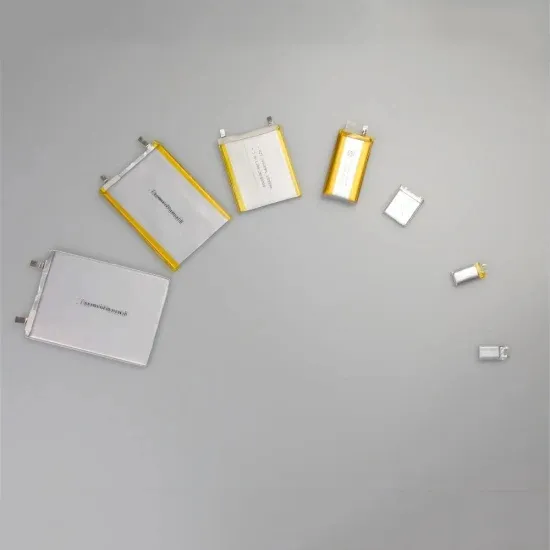

- Backup power supply for base station communication equipment

- Communication base station power supply equipment system

- Mobile base station power supply composition

- Mobile base station equipment photovoltaic power generation system

- Base station battery to mobile power supply

- Mobile base station power supply wind power system

- Base station wind power supply equipment installation

- Benin base station power supply equipment price

- Vietnam base station power supply equipment

- Base station power supply new energy storage

- Belgian communication base station wind and solar complementary lightning protection grounding

- Communication base station power supply changed to adjustable circuit

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.