Single crystal photovoltaic panel specifications and

Monocrystalline solar panels are a popular type of solar panel that is made from a single crystal of silicon. They are known for their high efficiency and durability, which makes

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Crystalline silicon photovoltaic (PV) cells are used in the largest quantity of all types of solar cells on the market, representing about 90% of the world total PV cell production in

Single crystal silicon photovoltaic panel size and weight

A monocrystalline solar panel is made from single-crystal siliconand is the most reliable type of solar panel. They have a uniform black colour and rounded edges -- popularly used residential

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

Solar Panel Sizes (Energy Use & Dimensions

Sep 2, 2024 · Solar panel sizes guide with residential & commercial solar panel dimensions, different types & how many solar panels you need for your home.

Size of single crystal silicon photovoltaic panels

The Czochralski process is currently the main route to fabrication of single- crystal silicon for both the microelectronics and solar PV industries. (favouring a rounded

Single crystal silicon photovoltaic panel size diagram

Monocrystalline solar panels are made from a single crystal of silicon, which is a semiconductor material that can convert sunlight into electrical energy. When sunlight hits the surface of the

Thin Film vs Crystalline Solar Panels: Which One

Aug 17, 2025 · Understanding Thin Film Solar Panels An examination of thin film solar panels reveals a photovoltaic technology that utilizes thin layers of

Single crystal photovoltaic panel specification size table

By interacting with our online customer service, you''ll gain a deep understanding of the various Single crystal photovoltaic panel specification size table featured in our extensive catalog,

Photovoltaic silicon panel size specification table

17. The PV module should have IS14286 qualification certification for solar PV modules (Crystalline silicon terrestrial photovoltaic (PV) modules -- design qualification and type

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · The Manufacturing Process Monocrystalline solar panels are created through a series of steps that include: Growing silicon ingots A crystal rod is dipped into molten silicon

Free-standing ultrathin silicon wafers and solar cells through

May 7, 2024 · Lightweight and flexible thin crystalline silicon solar cells have huge market potential but remain relatively unexplored. Here, authors present a thin silicon structure with

What Is A Monocrystalline Solar Panel? | Definition, Cost,

Feb 11, 2025 · A monocrystalline solar panel is a type of photovoltaic (PV) panel constructed from a single, continuous silicon crystal. This distinguishes them from polycrystalline panels, which

Crystalline Silicon Module

Crystalline silicon cell fabrication: Crystalline silicon PV cells are fabricated from the so-called "semiconductor silicon" that is prepared from metallurgical silicon by decomposition of SiHCl 3

Progress in n-type monocrystalline silicon for high

May 21, 2024 · To increase yield per crystal growth operation and reduce unit crystal growth cost, strategies such as larger starting charge sizes or pulling several crystals sequentially from a

Size of single crystal silicon photovoltaic panels

Feb 1, 2023 · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and development efforts that lead to

Silicon single crystals

Jan 1, 2019 · The single crystal growth methods, and resulting silicon structure, properties, and defects are extremely well studied and documented in the literature. However, single crystal

Evolution of Silicon Wafer Size

Jan 14, 2022 · Silicon wafers are divided into semiconductor wafers and photovoltaic wafers according to their uses. Photovoltaic silicon wafers can be single crystal silicon or

Single crystal silicon photovoltaic panel size diagram

What are monocrystalline solar panels? Monocrystalline solar panels are made from single-crystal silicon,resulting in their distinctive dark black hue. This uniform structure,with fewer grain

Single crystal silicon photovoltaic panel size and weight table

Solar Panel System Size (based silicon cells are fabricated from slices of either single-crystal or multi-crystalline silicon) sizes. This is a size increase of 20% to 30% above standard 2.0m x

Size of single crystal photovoltaic panels

The size of the silicon ingot depends on 3 factors: temperature gradient, cooling rate, and rotation speed. Creating Silicon Wafers; So far you have a huge single crystal silicon The typical lab

High-Efficiency Crystalline Photovoltaics | Photovoltaic

Apr 3, 2025 · High-Efficiency Crystalline Photovoltaics NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving

Single-Crystal Silicon: Photovoltaic Applications

Oct 2, 2020 · Introduction The vast majority of solar cells used in the field are based on single-crystal silicon. There are several reasons for this. First, by using this material, photovoltaic

Low cost single crystal CdZnTe-Silicon tandem PV

May 1, 2021 · In the last decade PV silicon cells and CdTe thin-film cells have made large gains in performance, cost, and installed energy capacity. Multi-crystalline silicon has gone from 14.5%

Silicon-based photovoltaic solar cells

Jan 1, 2012 · The dominant contributor to PV energy generation capacity, at present and for the foreseeable future, is silicon-based technology; in particular, crystalline (c-Si) and

5 Types Of Solar Panels Explained

Jun 24, 2024 · Monocrystalline Silicon Solar Panels Single-crystal panels, also called monocrystalline silicon panels, are one of the most mature solar energy technologies on the

Monocrystalline Silicon Cell

Monocrystalline silicon cells are defined as photovoltaic cells produced from single silicon crystals using the Czochralski method, characterized by their high efficiency of 16 to 24%, dark colors,

Chapter 1 History of Solar Cell Development

Jul 25, 2023 · The First Single-Crystal Silicon Solar Cell Table 1.3 summarizes the events between 1950 and 1959 leading to the practical silicon single-crystal PV device. The key

6 FAQs about [Single crystal silicon photovoltaic panel size standard]

What are crystalline silicon photovoltaic modules?

The Crystalline silicon photovoltaic modules are made by using the silicon crystalline (c-Si) solar cells, which are developed in the microelectronics technology industry. The PV solar panels are composed of these solar cells as part of a photovoltaic system to produce solar energy from sunlight.

How big is a monocrystalline solar panel?

Monocrystalline Solar Panels have typical heights of 64”, 76.5” (163, 194 cm), widths of 39”, 51.5” (99, 131 cm), and depths between 1.2”-2” (3-5 cm). Solar cell sizes are 6” x 6” (15 x 15 cm). Outdoor fixtures are the different appliances and equipment that serve users in an outdoor setting.

What is a photovoltaic (PV) solar panel?

This solar panel is a photovoltaic (PV) panel that offers several advantages over the standard solar panel size, making them a good alternative. Some of the benefits of this solar panel type include: Sleek weight and flexibility – because of its weight, this solar panel is easier to install in different locations.

Are polycrystalline solar panels a good source for residential solar panels?

Polycrystalline is also a good source for residential solar panels. These solar cells are made by depositing a thin layer of photovoltaic material onto a substrate such as glass, plastic, or metal. They are less efficient than crystalline cells but are sleek weight, flexible, and can be made in various sizes and shapes.

What is a typical solar panel size?

Most residential solar panels’ standard size range from 65 by 39 inches, or 17.3 square feet, to 78 inches by 39 inches, or 20.5 square feet. Average solar panel size — large or small solar system size — is available to produce different levels of energy output.

How many Watts Does a monocrystalline solar panel produce?

A monocrystalline residential solar panel typically comes in two sizes: 60-cell and 72-cell. The 60-cell panels are about 65 by 39 inches and have a power output of around 280-320 watts, and the 72-cell panels are about 77 by 39 inches and have more power output of around 340-400 watts.

Update Information

- Which photovoltaic panel is better single crystal silicon n-type or p-type

- How many watts can a single crystal silicon photovoltaic panel hold

- Single 800W photovoltaic panel size

- Single crystal 695wp photovoltaic panel

- Beirut single crystal photovoltaic panel charging pile manufacturer

- What is the output voltage of a 550w single crystal photovoltaic panel

- Standard photovoltaic panel 260w size

- Single crystal photovoltaic panel 780 cm wide 39 cm

- How much does a double-sided single crystal 550W solar photovoltaic panel cost per square meter

- 585kwp photovoltaic panel size

- What is the voltage of a single dcl photovoltaic panel

- 250W photovoltaic panel size

- Libya folding photovoltaic panel size

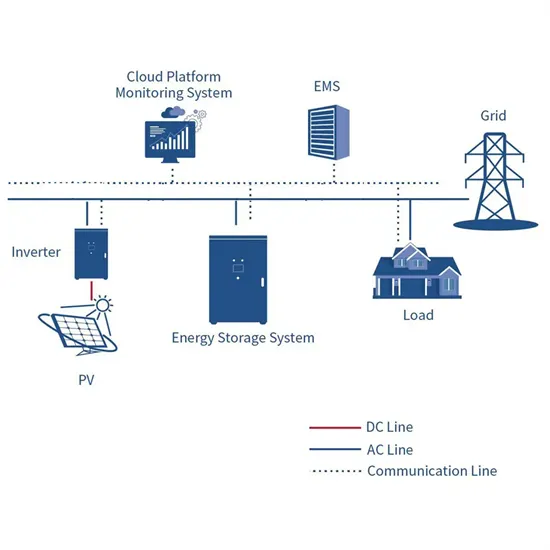

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.