Lithium-Ion Battery Charging Cabinet | Securall

Protect your facility and your team with Securall''s purpose-built Battery Charging Cabinets—engineered for the safe storage and charging of lithium-ion, lead-acid, and other

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements. Store batteries

Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

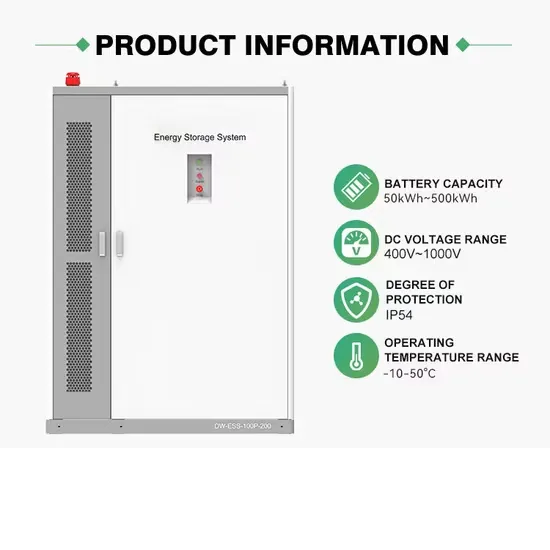

Standard Specifications for Lithium Battery Energy

AZE''''s 27U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

6 Battery Energy Storage Systems — Lithium | UpCodes

This section applies to battery energy storage systems that use any lithium chemistry (BESS-Li). Unoccupied structures housing BESS-Li must comply with NFPA 855, except where modified

Designing Industrial Battery Rooms: Fundamentals and

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

6 FAQs about [Requirements for special-shaped lithium battery station cabinets]

Are lithium battery storage cabinets safe?

Lithium battery storage cabinets have been available on the market for years; however, the lack of clearly defined testing procedures has led to consumer uncertainty and, in the worst case, serious safety hazards.

Are there guidelines for storing lithium-ion batteries at home?

Yes, there are unique guidelines for storing lithium-ion batteries at home. Proper storage practices ensure the safety and longevity of the batteries. These guidelines help mitigate the risks of fire, overheating, and reduced battery lifespan. Storing lithium-ion batteries requires attention to temperature, humidity, and physical conditions.

Why is proper storage important for lithium-ion battery safety?

Proper storage is critical for lithium-ion battery safety due to the inherent risks of overheating, short-circuiting, and chemical leakage that can lead to fires or explosions.

Do lithium ion batteries need a battery room?

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements. Store batteries at a temperature of 59°F (15°C). Also, refer to NFPA 70E for further safety guidelines, and ensure proper exhaust ventilation for off-gas events.

How do building codes affect lithium-ion battery storage?

Local jurisdictions may impose their own building codes concerning the storage of lithium-ion batteries. These codes can dictate structural requirements such as battery room construction, ventilation systems, and access control to minimize risks.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Update Information

- Technical requirements for customized lithium battery station cabinets

- Required test items for lithium battery station cabinets

- Base station energy storage lithium iron battery

- Lithium battery station cabinet safety signs

- Madagascar lithium battery station cabinet manufacturers ranked top ten

- Lithium battery station cabinet customized price latest

- China-Africa lithium battery station cabinet integration system

- Amman outdoor lithium battery station cabinet cost

- Requirements for lithium battery cells

- Turkmenistan lithium battery station cabinet system

- Power station energy storage battery policy requirements

- Base station lithium iron phosphate battery outdoor communication site

- Lithium cobalt oxide battery station cabinet cover

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.