plaquetteSRACK_A4_8pages03

Oct 3, 2022 · The recycling efficiency of these recyclers exceeds 75% of the nickel based battery weight (a level which exceeds the mandated recycling efficiency of 65% applicable to lead-acid

NICKEL CADMIUM BATTERIES: INDIVIDUAL DATA SHEET

Feb 4, 2005 · *** Refer to "Charge Methods for Ni-Cd Batteries" Battery performance and cycle life are strongly affected by how they are used. In order to maximize battery safety, please consult

Vented Single Cell Ni-Cd Battery Range

Mar 25, 2025 · We develop and manufacture Ni-Cd cells of highest quality, pushing the boundaries of this proven chemistry with innovative design features. Delivering customized

nickeL-cadmium Battery

May 25, 2020 · Vented Ni-Cd batteries are used in transport applications such as aircraft, diesel engine starters, and railways where large energy per weight and volume are critical. Ni-Cd

Battery Disposal & Recycling

Mar 5, 2025 · The availability of the nickel metal hydride battery played a crucial role in facilitating Europe''s banning of the nickel-cadmium battery in the EEC''s Battery Directive of 2009. Nickel

Ni Cd Battery Nickel Cadmium Market Research Report 2032

In 2023, the global Ni Cd Battery (Nickel Cadmium) market size was valued at approximately USD 1.2 billion, and it is projected to reach around USD 1.8 billion by 2032, growing at a CAGR of

Best Practices for Storing Ni-Cd Batteries – Leading Battery

Feb 8, 2025 · Ideal storage temperatures range between 10-25°C (50-77°F). Discharge Before Storage – To prevent self-discharge issues, Ni-Cd batteries should be stored in a fully

BBTDEn0100507:2574-Saft-IBG BB1st 5xpages a-w

Dec 21, 2016 · Specified worldwide Diverse installations such as Australia''s Sydney Opera House, and AGIP Refinery in Italy, depend on Saft Ni-Cd power back-up. From USA substations to

Ni-Cd Block battery range

Oct 24, 2023 · Saft''s commitment to research and development and innovative engineering ensures that our nickel-cadmium (Ni-Cd) batteries offer the very latest in design, quality and

Typical materials composition (by percentage

Mar 29, 2025 · The composition of the various constituents of Ni-Cd batteries by percentage weight used for automotive and portable electronic applications is

Weight of Nickel

Feb 21, 2025 · Cadmium is a dense metal, and its presence in the battery contributes significantly to the overall weight. For example, a typical Ni - Cd battery with a capacity of 1000 mAh may

Nickel-Cadmium Battery Specification Sheet with partial

Foreword : All information relates to Industrial nickel-cadmium batteries complying with IEC 62259 standard for partial gas recombination for use in floating stationary applications.

Nickel-Cadmium Battery Specification Sheet with partial

The battery shall be of double perforated pocket plate. It shall be housed in polypropylene containers. It is acceptable to have containers (including several cells in series) in order to

Ni-Cd Battery (Nickel Cadmium) Market Expansion: Growth

Apr 16, 2025 · The global Nickel-Cadmium (Ni-Cd) battery market, valued at $1076.3 million in 2025, is projected to experience steady growth with a Compound Annual Growth Rate (CAGR)

Nickel-Cadmium (NI-CD) Batteries

In commercial production since the 1910s, nickel-cadmium (Ni-Cd) is a traditional battery type that has seen periodic advances in electrode technology and packaging in order to remain viable.

Safety Data Sheet for Nickel Cadmium Batteries

Nov 19, 2020 · Note: W= 0.5 x Nominal voltage x lp / weight lp = current in Amperes delivered by a fully charged battery for half the nominal voltage at one second Kg = Average battery weight

Ni-Cd Battery Market: Netherlands | Mexico | South Africa

Jul 25, 2025 · Stay ahead of the curve with the new Ni-Cd Battery Market Report, your go-to resource for in-depth industry analysis. The market was valued at USD 3.

Electrical engineering: Nickel-Cadmium Battery

Aug 26, 2024 · Compared to modern batteries like lithium-ion, Ni-Cd batteries have a lower energy density, meaning they store less energy per unit of weight. Working Principle of Nickel

Nickel-Cadmium Batteries | Umbrex

Nickel-Cadmium (Ni-Cd) batteries are a type of rechargeable battery known for their durability, reliability, and ability to deliver high discharge rates. Invented in 1899 by Waldemar Jungner,

6 FAQs about [Weight of Ni-Cd Batteries in Containers in South America]

What is a NiCd battery made of?

In a NiCd battery, nickel oxide hydroxide is used to make the cathode, and the anode is made from metallic cadmium. An aqueous alkali solution is used as the electrolyte between the two electrodes. NiCd batteries are currently widely used for portable electronics applications, like lead-acid and lithium-ion batteries.

What is a nickel cadmium battery?

A Nickel Cadmium Battery is a type of rechargeable battery that contains a nickel electrode coated with reactive nickel hydroxide and uses potassium hydroxide as the cell electrolyte. These batteries have higher energy densities, are lighter than lead-acid batteries, and cool down during recharging, allowing for quick charging times.

What is HSL+ type of nickel cadmium battery?

HSL+ type of Nickel Cadmium battery is developed by HBL to supply power to critical and demanding applications like solar photovoltaic or renewable energy. These batteries are completely reliable with minimal maintenance, withstand deep discharges, rough treatment over long periods and operates at widest temperature range.

How do you dispose of a Ni-Cd battery?

DISPOSAL CONSIDERATIONS As with all battery systems, Ni-Cd cells must be collected separately from other waste and recycled. Never incinerate Nickel Cadmium batteries. Never dispose Ni-Cd cells as landfill. Nickel Cadmium batteries must be recycled.

Can Ni-Cd batteries be recycled?

As with all battery systems, Ni-Cd cells must be collected separately from other waste and recycled. Never incinerate Nickel Cadmium batteries. Never dispose Ni-Cd cells as landfill. Nickel Cadmium batteries must be recycled. Contact Storage Battery Systems LLC for information. 14. TRANSPORT INFORMATION

How long does a Ni-Cd battery last?

120mA (0.1It) x 16 hrs. 120mA (0.1It) x 16 hrs. 1200mA (1It) x 1.5 hrs. 1200mA (1It) x 1.5 hrs. 1200mA (1It) x 1.5 hrs. ̊C ̊C ̊F * 0.2It discharge capacity after charging at 0.1It for 16 hours. ** For reference only. *** Refer to “Charge Methods for Ni-Cd Batteries” Battery performance and cycle life are strongly affected by how they are used.

Update Information

- South America Energy Storage Batteries

- Outdoor UPS Sales in South America

- Exporting photovoltaic inverters to South America

- South America Centralized Grid-connected Photovoltaic Inverter

- South America PCM UPS Uninterruptible Power Supply

- Cheap battery cabinets in South America

- Regular photovoltaic combiner box in South America

- South America Outdoor Power Supply Factory

- Photovoltaic panels installed on rooftops in South America

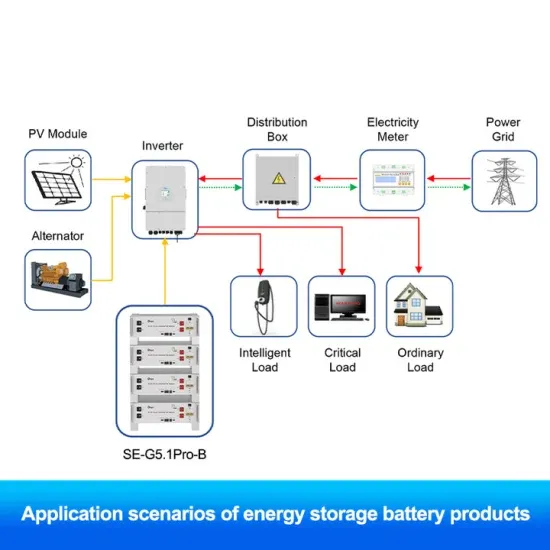

- Power Generation and Energy Storage in South America

- South America 10kWh outdoor power supply EK

- Direct sales of energy storage batteries in South Korea

- How big is the scale of energy storage containers

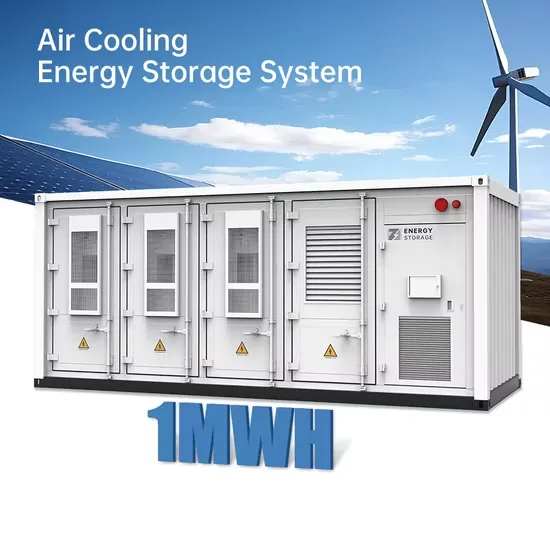

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

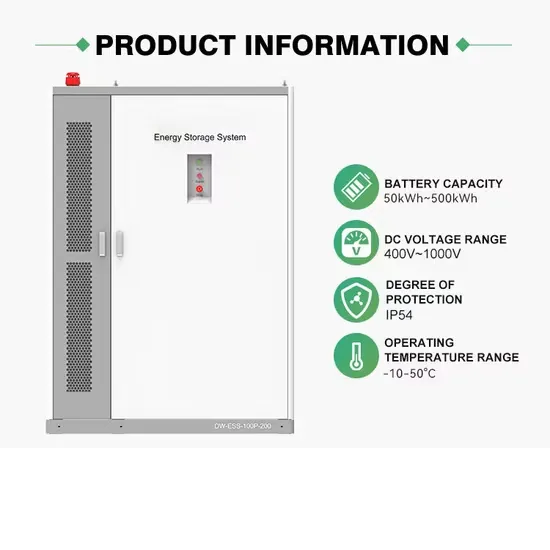

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.