How to Calculate Battery Size for Inverters of Any Size

Learn how many batteries for a 3000-watt inverter or a 1kVA inverter and more, right here at The Inverter Store. In order to size a battery bank, we take the hours needed to continuously run

How Many Batteries Do I Need for a 300 Watt

Dec 23, 2021 · On the flip side, a 300 watt solar panel needs no less than a 100ah battery to draw 1000W. A tiny solar battery sufficiently is assuming that you

How many batteries to run a refrigerator? A

Feb 5, 2024 · I get commissions for purchases made through links in this post. How many batteries to run a refrigerator? To run a refrigerator on batteries for

How to calculate battery capacity for inverter systems

Oct 27, 2016 · To find out how many batteries for your inverter. The rule is" maximize run time, minimize the battery size and cost." The formula is : Battery Capacity (WH)*Discharge

How Many Solar Panels Do I Need For a 3000 Watt Inverter?

If you need to run a lot of AC powered loads, a 3000 watt inverter can get the job done. These have become more affordable lately, but how many solar panels would you need to run a full

How Many Batteries Do You Need For a 300W Solar Panel?

Mar 15, 2025 · To find the required Ah battery for your home inverter, follow this guideline: For a 12-volt inverter, use 20% of its capacity. For a 24-volt inverter, use 10%. For example, a 500

Understanding Battery Capacity and Inverter Compatibility

Aug 20, 2024 · How Long Can a 100 Ah Battery Run a 1000W Inverter? To estimate how long a battery can run an inverter, we need to consider the power draw and the battery''s capacity.

How Many Batteries Do I Need for a 300 Watt

Dec 23, 2021 · Solar Inverter Load For 300W Solar Panels For the solar inverter, its load and term assume a gigantic part in deciding battery limit. The solar

Understanding Battery Capacity and Inverter Compatibility

Aug 20, 2024 · How Many Watt-Hours is 200 Ah? To accurately assess the energy capacity of a battery, converting amp-hours to watt-hours is essential. The formula for this conversion is

Here is how to select the best and reliable inverter battery

For example, one 12 V inverter with 100 Ah battery may give 2-hours'' backup for a certain load. It will give 4-hours'' backup for 180 Ah battery. A bigger battery costs more, takes up more space

Inverter Load Calculation: A Complete Guide for Your Home

Aug 17, 2025 · Use our free inverter load calculator to determine the right VA and Ah for your home. Learn how to calculate electricity load in kW for better power backup.

How Many Batteries For 300 Watt Solar Panel: A Complete

Dec 5, 2024 · Wondering how many batteries are needed for a 300-watt solar panel? This comprehensive article guides you through the essentials of solar panel systems, highlighting

6 FAQs about [How many ah batteries are required for a 300w inverter]

How long can a 100 Ah battery run a solar inverter?

A 100ah battery can supply 1000W of solar panel power to an inverter for 48 minutes. However this will completely drain the battery down to 0%. A lead acid battery has a 50% DOD so you have to double the capacity to 200ah. If you want to draw 1000W for longer than 48 minutes, get a larger battery or reduce the load.

What size inverter for a 200Ah battery?

To determine the appropriate inverter size for a 200Ah battery, consider the following: A 500VA inverter would be suitable, offering a balance between performance and battery life. For extended run times, consider larger inverters or additional batteries to meet higher power demands.

How many batteries do you need for inverter?

Based on this inverter voltage calculation, he need 4 no. of 150Ah lead acid battery. If he wants to install the latest technology battery, then he need 1 no. of CAML100 lithium battery. If he runs 2000 watt load, then it can give 2 hrs. backup time.

What is the capacity of an inverter battery?

The capacity of an inverter battery, measured in ampere-hours (Ah), determines how much power it can store and supply over time. A higher Ah rating means the battery can provide backup power for a longer duration before requiring a recharge. The basic formula for calculating battery capacity is:

Can a 1000 watt inverter run a 100 Ah lithium battery?

In reality, factors such as inverter efficiency and battery discharge characteristics might affect the actual run time. When pairing a 100 Ah lithium battery with a 1000 watt inverter, it is crucial to ensure compatibility to achieve optimal performance.

How many watts can a 200 Ah battery power?

For a 200 Ah battery, the calculation depends on the battery’s voltage. Assuming a 12V battery: Wh=200 Ah×12 V=2400 Wh Thus, a 200 Ah battery at 12 volts has a capacity of 2400 watt-hours. This metric is vital for determining how long a battery can power specific devices and for evaluating the overall energy storage capabilities.

Update Information

- How many Ah batteries are suitable for 24v3000w inverter

- How much energy storage is required for a 60kw inverter

- How many batteries does a 1600w inverter require

- How many Ah batteries does a 100 watt solar panel use

- How big a battery should a 12v inverter battery be

- How many types of cylindrical lithium batteries are there

- How many communication base station inverter companies are there in Tajikistan

- How big an inverter should I install for a 24v light truck

- How much does a 48v4000w inverter cost

- How many photovoltaic panels can be connected to the inverter

- How to find a communication base station inverter and connect to the grid

- How much does it cost to buy an inverter with energy storage battery

- How much AC power does the inverter output

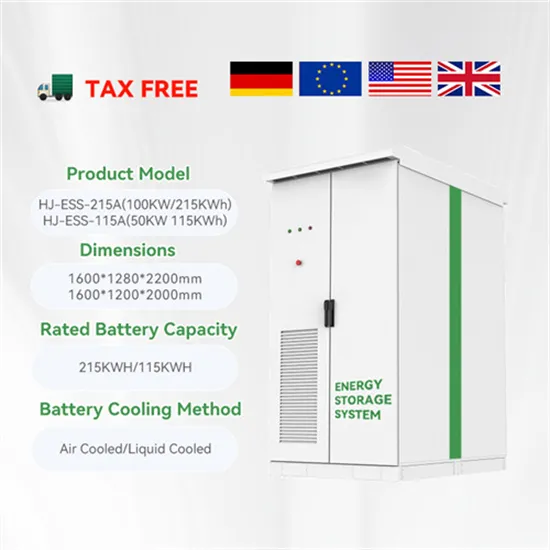

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.